Essential Guide To Central Heating Design

View the essentials of central heating design with our comprehensive guide. Find innovative solutions to optimising your heating system.

Introduction to Central Heating Design

Central heating design is a critical aspect of modern building infrastructure, ensuring optimal comfort and energy efficiency.

As demand for sustainable and effective heating solutions grows, the importance of a well-conceived central heating system cannot be overstated.

A properly designed system not only provides consistent warmth but also significantly reduces energy consumption and operational costs.

By understanding the principles and components involved, engineers and designers can create systems that are both highly functional and environmentally-friendly.

Key Components in Central Heating

Central heating systems are composed of several critical components that work together to provide consistent and efficient warmth throughout buildings.

At the heart of the system is the heat source, which can range from traditional boilers to modern heat pumps.

These devices are responsible for generating the heat that will be distributed throughout the building.

Equally important is the heat distribution network, which includes an array of pipes and radiators or underfloor heating elements designed to transfer the generated heat to different areas.

Meticulously plan and install this network to ensure uniform temperature distribution and optimal performance.

Another vital element of central heating systems is the control mechanism, which includes thermostats, timers, and advanced control panels.

These devices allow users to regulate temperature settings precisely, ensuring comfort and energy efficiency.

Additionally, the expansion tank and circulation pump play crucial roles in maintaining system pressure and ensuring that heated water or air is effectively circulated throughout the system.

Understanding the function and interplay of these components is essential for designing and maintaining reliable and efficient central heating systems.

By mastering these key elements, engineers and designers can create solutions that meet the highest standards of performance and sustainability.

Heat Emitters

A heat emitter is any component that emits heat to a building space.

Heat emitters can take many different forms, the most common are:

Radiators

Radiators are traditionally common, cheap and easy to install.

However, their operational costs can exceed other heat emitters as they are less efficient at heating up spaces within buildings.

They are usually located in the coldest part of the room i.e. below the windows.

Radiators are not as effective with heat pump systems as they are with traditional gas boiler systems.

This is because their surface area suits higher water temperatures (~70°C) that traditional gas boilers operate at.

With heat pump systems, because their water circulates at lower temperatures (~40°C), radiators often need to be

significantly larger with larger pipework supplying them so their surface area can heat the space to the desired temperature.

Underfloor Heating

Although they are less common, more expensive and difficult to install, they have lower operational costs due to

their higher efficiency and provide better comfort for the occupants.

The manifolds for underfloor heating are generally located central to the zone they are supplying to ensure optimised performance.

It also needs to be accessible but in a location that is out of view as it is not aesthetic.

Underfloor heating is more suited to heat pump systems than radiators, due to their large surface area, which is great for emitting and maintaining temperatures that are within the heat pump’s range.

Feed and Return Pipes

Hot water is supplied from the heat source to each heating element through a pipe network.

This pipe network comprises two separate systems:

- Feed pipes that supply water from the heat source to the heat emitters

- Return pipes that circulate the water back to the heat source to be reheated

Feed and return generally run parallel, making them easy to install.

Route them efficiently to use fewer materials and avoid extra heat and friction loss through the pipes.

Heat Pump

The heat pump is a critical piece of the system as it is the heat source for the building.

It is important to locate the heat pump in the best position possible.

The main considerations for choosing the location are:

- As close to the rest of the system as possible to prevent unnecessary pipe runs

- Keeping it out of view of entrances and windows as they are not aesthetic

- Avoiding areas where occupants spend time as the noise could be a nuisance – MCS limit noise to 42.0 dB(A)

- Locating it in a shady area to avoid overheating during the summer months

- Avoiding areas where there is the possibility for it to be damaged by objects like falling branches

- Locating it in an area that has good airflow and room for maintenance

Buffer Tank (Volumiser)

Buffer tanks (also known as a volumiser) store water to increase the total system water volume and in turn reduce the cycling of a heat pump.

The buffer tank is only required if the heat pump is going to cycle too frequently.

The additional hot water storage the buffer tank provides reduces the heat pump’s on/off switching, which in turn reduces energy consumption of the heat pump.

These are generally located in the garage, basement or attic.

They can also be located outside if they have sufficient insulation.

When deciding on the buffer tank’s location, the main considerations are:

- As close to the rest of the system as possible to prevent unnecessary pipe runs

- Locating it in an area that has room for maintenance

- Keeping it out of view of entrances and windows as they are not aesthetic

- Locating it in an area where a leak would not be catastrophic

Domestic Hot Water Cylinder

A domestic hot water cylinder stores hot water for domestic use, such as showers and sinks.

The heat pump’s hot water should not be used directly for domestic purposes. However, it can increase the temperature of the cylinder’s incoming cold water.

An electrical immersion heater often supplements this process to raise the temperature to 60°C or higher.

The cylinder is generally located in the garage, basement or attic.

They can also be located outside if they have sufficient insulation.

When deciding on the cylinder’s location, the main considerations are:

- As close to the rest of the system as possible to prevent unnecessary pipe runs

- Locating it in an area where electricity is relatively easy to connect

- Keeping it out of view of entrances and windows as they are not aesthetic

- Locating it in an area that has room for maintenance

- Locating it in an area where a leak would not be catastrophic

Diverter Valve

Diverter valves are on the tee where the system splits off to the domestic hot water cylinder and heat emitters.

The diverter valve opens and closes to direct heated water to either the heating system or the hot water cylinder.

The valve chooses the domestic hot water cylinder as the priority.

Without the diverter valve, sizing the heat pump for the combined load of the heating system and the domestic hot water cylinder would be overkill.

It’s important to ensure there are no heat emitters between the heat pump and diverter valve, so it performs correctly.

Recirculation Pumps

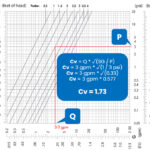

Recirculation pumps need to do two things:

- Circulate the water through the pipes fast enough to ensure the temperature of the water does not fall below the chosen Delta T

- Provide enough pressure for the water to circulate at the required flow rate

The smaller the Delta T, the higher the flow rate.

This is because the pump needs to move the water faster to prevent it from being exposed to the cold surfaces of the pipes and heat emitters for too long, thereby minimising temperature loss.

Generally, the faster the water is flowing, the higher velocity and pressure drop there will be too.

The recirculation pump is best located adjacent to the actual heat pump.

Commonly, installers place them on the heat pump’s feed or return side.

As the temperature is cooler on the return side, some industry experts argue that it’s the better location as it extends its life.

Effective Central Heating Design

Effective central heating design is pivotal in achieving optimal comfort and energy efficiency in any building.

A foundational aspect of this process is conducting accurate heat loss calculations.

These calculations are essential for determining the precise amount of heat required to maintain desired indoor temperatures, taking into account factors such as insulation, window placement, and building orientation.

Accurate heat loss assessments prevent the system from being overburdened or underperforming, which improves energy efficiency and reduces operational costs.

Equally crucial is the accurate sizing of equipment.

Selecting boilers, radiators, and pumps sized appropriately for the building’s specific requirements enables the system to operate at peak efficiency.

Oversized equipment can lead to unnecessary energy consumption and increased wear and tear, while undersized components may struggle to maintain comfortable temperatures.

Precise equipment sizing, therefore, is key to achieving a balance between performance and energy use.

System balancing is another integral aspect of effective central heating design.

This involves adjusting the flow of heat to different areas of the building to ensure uniform temperature distribution.

Proper balancing prevents some areas from becoming excessively warm while others remain cold, thus enhancing overall comfort and efficiency.

By prioritising accurate heat loss calculations, precise equipment sizing, and meticulous system balancing, engineers and designers can create central heating systems that deliver reliable performance and meet the highest standards of energy efficiency.

Central Heating Design Software with h2x

h2x Engineering’s central heating design tool provides engineers and designers with intuitive features to simplify the design process and enhance system performance.

From heat loss calculations to equipment selection and system layout, h2x’s solution delivers comprehensive functionality supported by industry-leading expertise.

With its user-friendly interface and advanced simulation capabilities, h2x’s software sets a new benchmark for efficiency and innovation in central heating design.

Book a demo or start a free trial with h2x today to explore how we can help you improve your workflow for designs and calculations!

Conclusion

In summary, central heating design is a sophisticated and essential element of modern building infrastructure, requiring a comprehensive understanding of various components and their interactions.

From the heat source and distribution network to control mechanisms and system balancing, each aspect plays a vital role in ensuring efficient and consistent warmth throughout a building.

Mastery of these elements, combined with precise heat loss calculations and accurate equipment sizing, empowers engineers and designers to create systems that are not only functional but also environmentally responsible.

By focusing on these critical areas, professionals can develop central heating systems that provide optimal comfort and efficiency, ultimately contributing to lower operational costs and reduced energy consumption.

h2x Engineering supports this process with innovative tools and expert guidance, setting new standards for excellence in central heating design.

As the industry continues to evolve, embracing these best practices and advanced technologies will be key to meeting the growing demand for sustainable and effective heating solutions.

FAQs

What are the latest advancements in central heating technology, and how do they compare to traditional systems?

The latest advancements in central heating technology include the development of smart thermostats, which allow for more precise temperature control and energy management through remote access and automation.

Additionally, modern heat pumps have become more efficient, with some capable of providing both heating and cooling.

These advancements often feature better insulation materials and improved designs that minimise heat loss, making them significantly more efficient compared to traditional systems.

Compared to older technologies, these innovations offer enhanced comfort, lower energy consumption, and greater ease of use.

How do you integrate central heating systems with renewable energy sources such as solar panels or geothermal systems?

Central heating systems can be effectively integrated with renewable energy sources like solar panels and geothermal systems.

Use solar thermal panels to heat water, which then circulates through the heating system, reducing reliance on fossil fuels.

Geothermal systems use the stable temperatures of the earth to provide heating and cooling, offering a sustainable alternative.

These integrations not only reduce the carbon footprint of the heating system, but also lower energy costs over time.

Proper planning and investment in these technologies can result in a more sustainable and cost-effective heating solution.

What are the typical costs associated with installing and maintaining a central heating system, and how can homeowners maximise their investment?

The costs associated with installing a central heating system can vary widely depending on the type of system, the size of the building, and the complexity of the installation.

Initial installation costs can be significant, but the long-term savings on energy bills and maintenance can make it a worthwhile investment.

To maximise their investment, homeowners should consider the efficiency of the system, potential savings on energy bills, and the availability of government incentives for energy-efficient upgrades.

Regular maintenance and timely upgrades can also help prolong the system’s lifespan and enhance its performance.

What are the best practices for ensuring the longevity and reliability of a central heating system, including regular maintenance and troubleshooting common issues?

To ensure the longevity and reliability of a central heating system, it is essential to follow best practices for maintenance and care.

This includes regular servicing by qualified professionals to check for and address any issues such as leaks, corrosion, or wear and tear on components.

Homeowners should also routinely check and replace filters, bleed radiators to remove trapped air, and ensure that thermostats and control systems are functioning correctly.

Addressing minor issues promptly can prevent them from developing into major problems, thus maintaining the efficiency and reliability of the system.

How can smart home technology and IoT devices be incorporated into central heating systems for enhanced control and efficiency?

Smart home technology and IoT devices can significantly enhance central heating systems by providing advanced control and monitoring capabilities.

Smart thermostats, for example, can learn a household’s schedule and adjust heating accordingly to save energy.

They can also be controlled remotely via smartphone apps, allowing users to adjust settings on the go.

IoT sensors can monitor temperature, humidity, and occupancy, optimising the system’s performance based on real-time data.

Integrating these technologies can lead to improved energy efficiency, increased comfort, and reduced operational costs, making central heating systems more responsive and adaptive to the needs of the occupants.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP