Glycol in Heating and Cooling Systems – What are the Implications?

Glycol is a substance commonly used in heating and cooling systems for its freeze protection capabilities. In this blog, we will discuss what glycol is, why it's used in heating and cooling systems, and how it affects system calculations.

Download your free PDF of this article below.

Glycol is a substance commonly used in heating and cooling systems for its freeze protection capabilities.

In this blog, we will discuss what glycol is, why it’s used in heating and cooling systems, and how it affects system calculations.

What is Glycol?

Glycol is a type of organic compound characterized by the presence of multiple hydroxyl (-OH) groups.

There are several types of glycols, but the most commonly used in heating and cooling systems are ethylene glycol and propylene glycol.

Glycol is typically mixed with water to create a solution that provides freeze protection, corrosion resistance, and efficient heat transfer.

Why Use Glycol?

The primary reasons for using glycol in heating and cooling systems include:

- Freeze Protection:

- Glycol lowers the freezing point of the fluid, preventing freezing in low-temperature environments and protecting the system from damage.

- Corrosion Resistance:

- Glycol solutions often contain corrosion inhibitors that protect the system components from corrosion and prolong their lifespan.

- Heat Transfer:

- Glycol solutions have excellent heat transfer capabilities, making them ideal for use in heating and cooling applications.

How Does Glycol Affect Friction Loss Calculations?

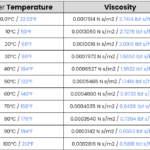

The presence of glycol in a system increases the fluid’s viscosity, which in turn affects the friction loss calculations.

You can learn more about Friction Loss Calculations here.

Higher viscosity fluids experience greater resistance to flow, resulting in increased friction losses.

When designing a glycol-based system, it is essential to account for these increased losses to ensure proper pump and pipe sizing.

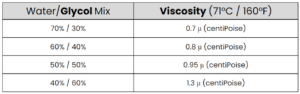

You can see the viscosity for various water / glycol mixes in the table below:

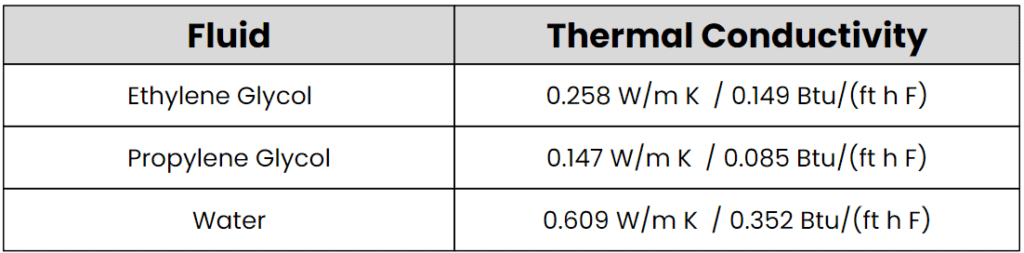

How Does Glycol Affect the Thermal Conductivity of the System?

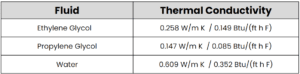

Glycol solutions generally have lower thermal conductivity compared to pure water.

This reduction in thermal conductivity means that glycol-based systems generally require higher flow rates to achieve the desired heat transfer performance.

Implications on System Sizing When Adding Glycol:

Adding glycol to a system has several implications for system sizing:

- Heat Source Load:

- The reduced thermal conductivity of glycol solutions may necessitate a larger heat source (heat pump, boiler, heat exchanger, etc.) to compensate for the loss in heat transfer efficiency.

- Recirculation Pump Size:

- Due to the increased viscosity and friction losses caused by glycol, larger recirculation pumps will generally be required to maintain adequate temperature with the increased flow rates and friction losses.

- Pipe Sizes:

- Increased viscosity may also necessitate larger pipe sizes to minimise pressure drops and ensure optimal flow rates throughout the system.

Conclusion on Glycol in Heating and Cooling Systems

Using glycol in heating and cooling systems offers numerous benefits, such as freeze protection, corrosion resistance, and efficient heat transfer.

However, it is essential to understand how glycol affects system calculations, such as friction losses and thermal conductivity, to ensure proper system sizing and optimal performance.

By considering these factors, you can effectively implement glycol into your heating and cooling systems for reliable and efficient operation.

The video below gives an overview of the difference that the glycol mixture has on a system’s sizing calculations:

FAQs

Can I mix different types of glycol?

Mixing different types of glycol is generally not recommended, as it can lead to unpredictable performance and compatibility issues with system components.

How often should I replace the glycol in my system?

The frequency of glycol replacement depends on factors such as system operating conditions, glycol type, and concentration.

Regular testing and monitoring of the glycol solution can help determine when it should be replaced.

What is the difference between ethylene glycol and propylene glycol?

Ethylene glycol and propylene glycol are both widely used in heating and cooling systems, but they have some critical differences.

Ethylene glycol generally provides better heat transfer and freeze protection compared to propylene glycol but is toxic and can be harmful if ingested or released into the environment.

In contrast, propylene glycol is considered non-toxic and environmentally safer, making it a preferred choice for applications where toxicity is a concern.

How do I determine the appropriate glycol concentration for my system?

The optimal glycol concentration depends on factors such as the desired freeze protection level, heat transfer requirements, and system materials.

Generally, a glycol concentration of 30% to 50% is recommended for most heating and cooling systems.

It is essential to consult the manufacturer’s guidelines to determine the appropriate concentration for your specific application.

Can glycol be used in potable water systems?

Glycol is generally not recommended for use in potable water systems due to its potential toxicity, especially in the case of ethylene glycol.

In situations where freeze protection is necessary for potable water systems, alternative solutions such as heat tracing or insulation should be considered.

h2x will provide accurate friction loss calculations for your design based all of your chosen temperatures, fluid mixtures, and pipe properties.

In addition, h2x provides automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems mean that you can focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start your free trial today to discover how h2x can help you improve your design and calculation workflow.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP