Understanding Flow Coefficient: A Guide for Valve Sizing

Learn how flow coefficient (Cv) impacts valve sizing. Explore their calculation, importance in fluid dynamics, applications, and more in our guide today!

Have you ever wondered how to ensure the optimal performance of fluid systems?

One secret lies in selecting the right valve size, and the key to achieving this is understanding the flow coefficient (Cv).

A precise understanding of Cv is crucial for engineers and technicians alike, as it helps determine the appropriate valve size for a specific application, thus avoiding potential issues and inefficiencies.

In this guide, we will dive into the concept of flow coefficient, its variables, and how it plays a vital role in valve sizing.

We will also explore how to calculate Cv for different media types, such as liquids, gases, and steam, and discuss the importance of differential pressure in valve sizing.

Finally, we will compare Cv and Kv, two commonly used flow coefficients, and provide guidance on choosing the right flow coefficient for your needs.

Understanding Flow Coefficient (Cv)

The valve flow coefficient, often denoted as Cv, measures the fluid flow rate through a control valve.

It is a crucial factor in valve sizing as it helps determine the appropriate valve size for optimal performance.

The valve flow coefficient Cv is expressed as a percentage of the maximum possible flow rate, considering the corresponding pressure drop.

Cv, also known as ‘Valve Flow Coefficient’, is a practical definition used to measure the flow rate of water.

It quantifies the rate at which a valve can pass a certain volume of water at a particular pressure drop.

The measurement typically occurs when water with a temperature of 60 °F (16 °C) flows through a valve with 1 psi (6.9 kPa) pressure drop across it.

A valve’s Cv rating directly affects its flow capacity, with higher ratings resulting in greater water flow capacity.

The Cv value is indicated on the valve’s product description or specifications label and is utilised to determine the correct sized valve based on the required flow rate and pressure drop.

If required, it is advisable to select a valve with a Cv value higher than the calculated one. This provides you with a greater flow rate and it safeguards against potential changes in pressure or flow rate.

Valve Flow Coefficient Variables

Several factors influence the flow coefficient of a valve, including:

- The valve’s internal geometry

- Fluid properties, such as viscosity, density, and temperature

- The valve’s size

- The presence or absence of piping reducers adjacent to the valve

All of these factors play a role in determining the flow coefficient.

The desired flow rate also influences the flow coefficient of a valve.

Higher flow rates necessitate larger valves with higher flow coefficients to ensure enough flow capacity for the system requirements.

Thus, an accurate understanding of the fluid properties and valve characteristics is essential in determining the correct Cv value for a specific application.

Pressure Drop and Cv

Pressure drop is a critical factor in calculating Cv and plays a significant role in valve sizing.

The desired pressure is essential to consider, as pressure drop is the difference in fluid pressure between the inlet and outlet of the valve, often resulting from resistance to flow in the valve and piping system.

It can be determined by either consulting standard graphs or by comparing the upstream fluid pressure and downstream pressure.

Taking pressure drop into account when calculating Cv is essential for selecting the right valve size, as it directly influences the flow capacity of the valve.

By accurately calculating pressure drop, engineers can ensure optimal valve sizing and avoid potential issues, such as:

- Choked flow

- Inadequate flow capacity

- System inefficiencies

- Damage

Calculating Flow Coefficient for Different Media

Different media types, such as liquids, gases, and steam, require specific calculations for flow coefficient due to their unique physical properties and behavior.

These calculations take into account factors such as density, temperature, and pressure drop, ensuring accurate valve sizing for each type of fluid.

By understanding the distinct formulas for each medium, engineers can optimise the performance of their fluid systems and avoid potential issues associated with improper valve sizing.

In the following subsections, we will look into the specific calculations for the flow coefficient for liquids.

Gaining a thorough understanding of these formulas will enable you to accurately size control valves for various media types, ensuring optimal system performance and efficiency.

Flow Coefficient for Liquids

The flow coefficient for liquids is based on the flow rate of water in GPM at 60°F and 1 psi pressure drop across the valve.

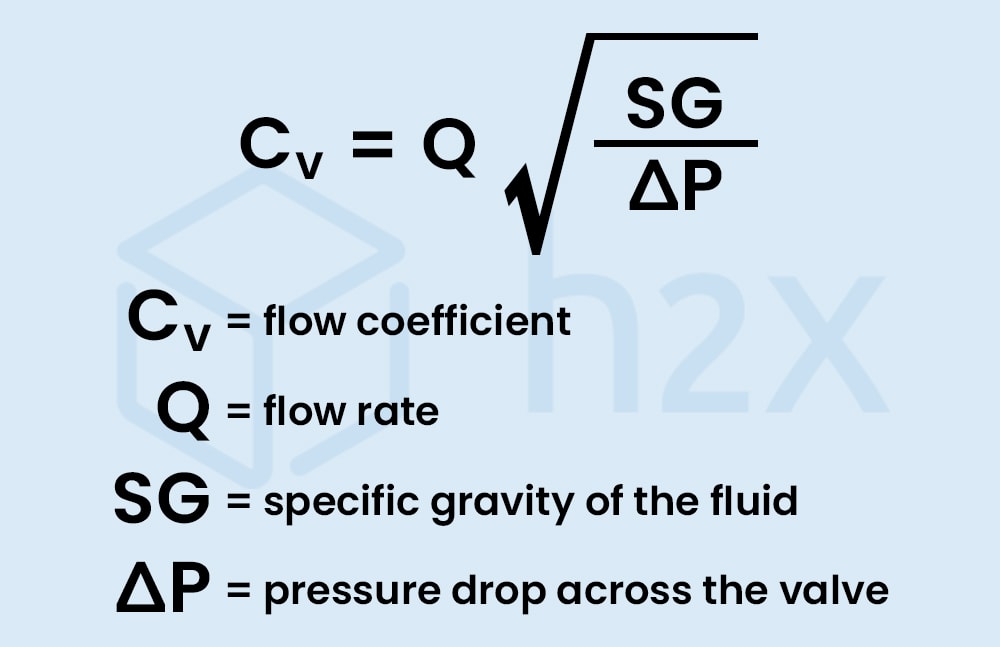

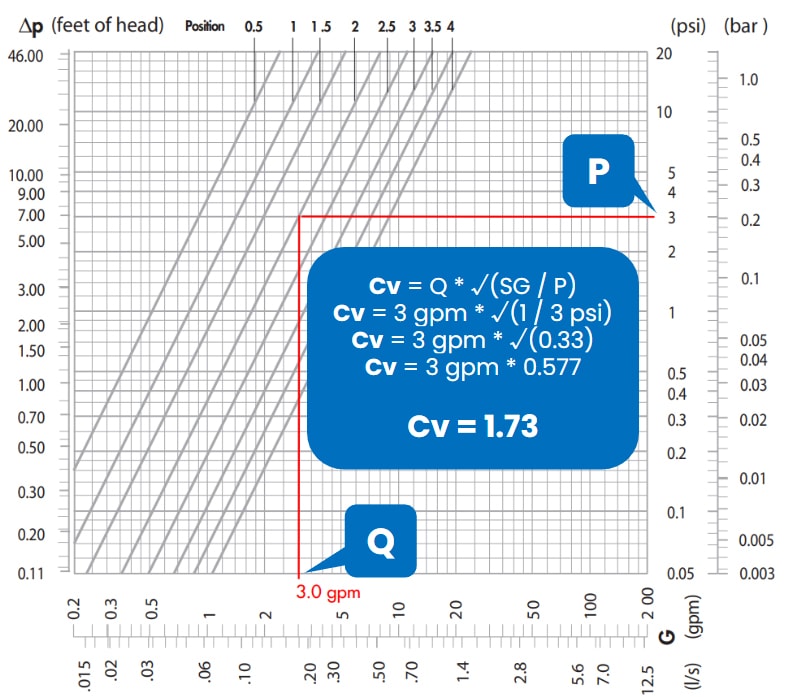

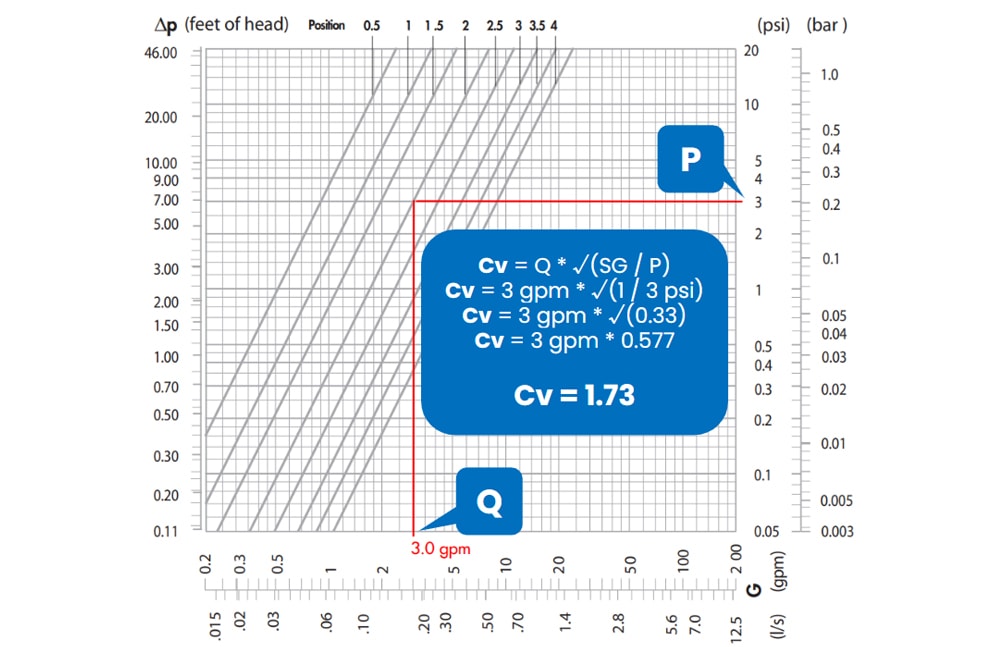

The formula for calculating the flow coefficient (Cv) for liquids is:

Cv = Q * sqrt(SG / P)

Q is the flow rate in gallons per minute (GPM)

SG is the specific gravity of the fluid

P is the pressure drop in pounds per square inch (psi).

An increased specific gravity leads to an increased flow rate, and a higher pressure drop results in a decreased flow coefficient.

By understanding this formula and the significance of specific gravity and pressure drop, engineers can accurately size valves for liquids, ensuring optimal performance and avoiding potential issues such as inadequate flow capacity or excessive pressure drop.

This knowledge is essential for the proper design and operation of fluid systems that handle liquids.

Control Valve Sizing and Flow Capacity

Proper valve sizing is essential for optimal performance, and flow capacity plays a significant role in determining the correct valve size.

Flow capacity is the maximum amount of fluid that can pass through a valve and is determined by utilising the flow coefficient (Cv) of the valve, the pressure drop across the valve, and the fluid density.

By understanding the relationship between flow capacity and valve size, engineers can ensure the correct valve size is selected for a given flow rate and pressure drop.

Undersized vs. Oversized Valves

An undersized valve has restricted flow capacity and could potentially cause a higher pressure drop across the valve, leading to poor performance and potential harm to the system.

Conversely, an oversized valve may have inadequate controllability and can exacerbate issues within the system, in addition to being more costly.

Therefore, it is crucial to select the right valve size for a given application to ensure optimal performance and efficiency.

By understanding the drawbacks of using undersized and oversized valves, engineers can make informed decisions when selecting the appropriate valve size for their fluid systems.

This knowledge helps to prevent potential issues and inefficiencies associated with improper valve sizing, ensuring optimal system performance and longevity.

Differential Pressure and Valve Sizing

Differential pressure, or the difference between inlet pressure and outlet pressure, is a crucial factor in valve sizing and flow capacity calculations. By taking differential pressure into account, engineers can:

- Accurately size valves for a given flow rate and pressure drop

- Ensure optimal valve performance

- Avoid potential issues such as choked flow or inadequate flow capacity.

Understanding the importance of differential pressure in valve sizing and flow capacity calculations helps engineers design and operate fluid systems that function optimally.

By selecting the appropriate valve size based on differential pressure, engineers can ensure the efficient operation of their fluid systems and prevent potential issues associated with improper valve sizing.

Cv and Kv: Comparing Flow Coefficients

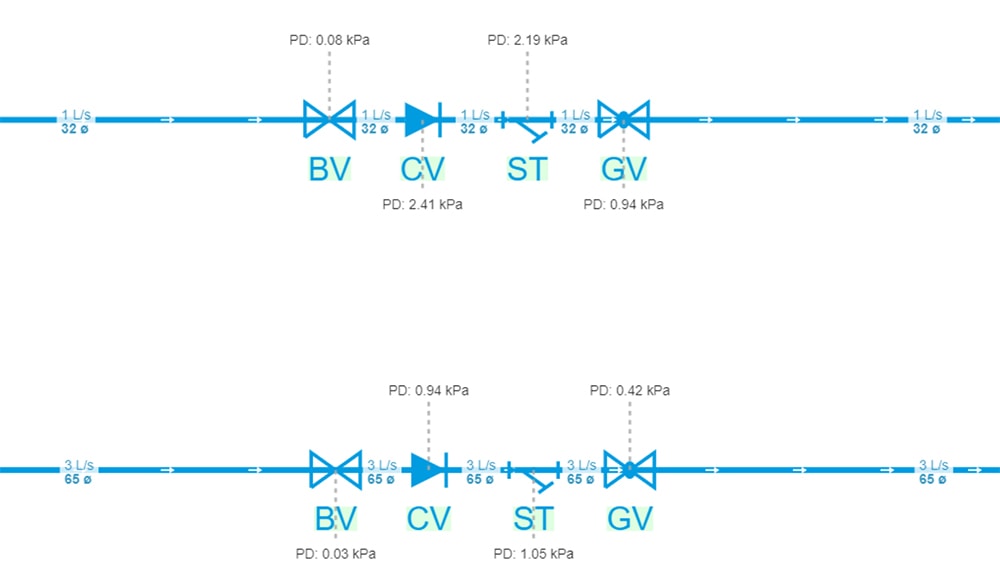

This image taken from h2x’s design software shows how the pressure drop across a valve changes as the pipe size, flow rate, and velocity change, due to the Cv/Kv value.

Even though they both differ in units and measurement systems, Cv and Kv are both flow coefficients used to measure fluid flow rate through a valve.

Cv is primarily utilised in the Imperial unit system and denotes the quantity of US gallons per minute of water at 60 °F that will flow through a valve with a pressure drop of 1 psi.

Conversely, Kv is employed in the metric unit system and indicates the amount of water that can pass through a valve in cubic meters per hour with a pressure drop of one bar.

In the following subsections, we will provide the conversion formulas for Cv and Kv, helping users switch between the two flow coefficients.

By understanding the differences between Cv and Kv and their respective units and measurement systems, engineers can accurately size valves for various applications, ensuring optimal system performance and efficiency.

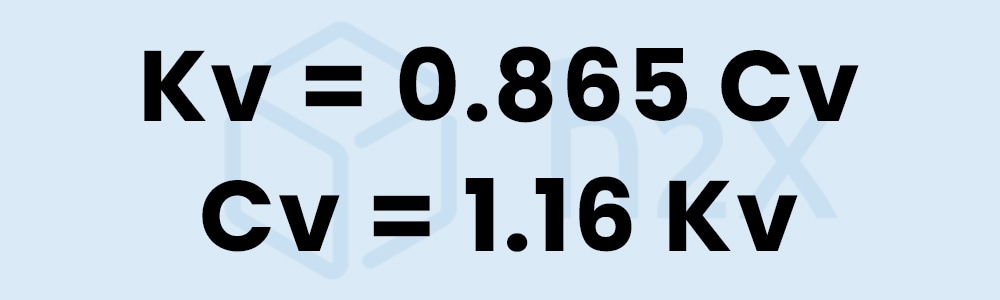

Conversion Formulas for Cv and Kv

To help users switch between Cv and Kv, the conversion formulas are provided: Kv = 0.865 Cv and Cv = 1.16 Kv.

These formulas allow users to easily convert between the two flow coefficients, ensuring accurate valve sizing regardless of the measurement system used.

For instance, if the Cv of a valve is 10, then the Kv of the valve is 8.65.

By understanding these conversion formulas, engineers can accurately size valves for various applications, regardless of the measurement system used.

This knowledge ensures optimal system performance and efficiency, preventing potential issues associated with improper valve sizing.

Choosing the Right Flow Coefficient

Selecting the appropriate flow coefficient is essential for accurate valve sizing and optimal system performance.

The type of fluid, the pressure drop across the valve, and the desired flow rate should be taken into account when selecting a flow coefficient.

By accurately calculating Cv or Kv values, engineers can ascertain the size of the valve required for a specific application.

By choosing the right flow coefficient, engineers can ensure optimal valve sizing and system performance, preventing potential issues associated with improper valve sizing.

This knowledge is essential for the proper design and operation of fluid systems, as it helps to avoid potential issues such as choked flow or inadequate flow capacity.

Conclusion

Throughout this guide, we have explored the importance of understanding the flow coefficient and its crucial role in valve sizing for optimal system performance.

By comprehending the variables affecting valve flow coefficient, calculating Cv values for different media types, and considering differential pressure in valve sizing, engineers can design and operate fluid systems that function efficiently and effectively.

Furthermore, recognising the differences between Cv and Kv flow coefficients and their respective units and measurement systems ensures accurate valve sizing across various applications.

The journey to mastering flow coefficient and valve sizing is a continuous process, but with the knowledge gained from this guide, you are well on your way to optimising your fluid systems.

As you apply these concepts to your work, you will not only improve the performance of your systems, but also contribute to the overall success of your projects.

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The software provides automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems, allowing you to focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

Frequently Asked Questions

What do you mean by flow coefficient?

The Flow Coefficient (Cv) is a measure of the flow capacity of a valve, defined as the volume of water at 60°F (in US gallons) that will flow through it per minute with a pressure drop of 1 psi across the valve.

What does a higher flow coefficient mean?

A higher flow coefficient indicates that a larger amount of fluid is able to pass through the valve with a given pressure drop, and the valve opening is also greater.

How do you calculate flow coefficient?

To calculate the valve flow coefficient, Cv, simply plug in the values for your variables into the equation Cv = Q (SQ/P). This should provide you with the result of the calculation.

What is the valve flow coefficient (Cv)?

The valve flow coefficient (Cv) is a measure of the rate of fluid flow through a control valve, and helps determine the correct size for optimal performance.

It is important to select the right size valve for the application to ensure optimal performance. The Cv value is used to calculate the flow rate of the valve, and is determined by the valve’s size, design, and operating conditions.

How do Cv and Kv differ?

Cv and Kv are both measures of flow, but Cv is commonly used in the Imperial unit system and Kv in the metric unit system. Cv is defined as the number of US gallons per minute of water at 60 °F passing through a valve with a pressure drop of 1 psi, while Kv is the quantity of water that can pass through a valve in cubic meters per hour with a pressure drop of one bar.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP