What is District Heating?

District heating systems are gaining traction worldwide for their energy efficiency and sustainable potential. This comprehensive guide will help you understand the ins and outs of district heating, from what it is and how it works, to its renewable capabilities.

Download your free PDF of this article below.

Introduction

District heating systems are gaining traction worldwide for their energy efficiency and sustainable potential.

This comprehensive guide will help you understand the ins and outs of district heating, from what it is and how it works, to its renewable capabilities.

What is a District Heating System?

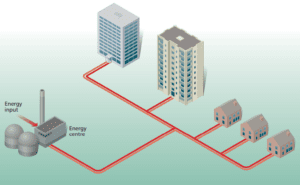

A district heating system is a centralised network that distributes heat to multiple buildings/apartments.

The heat is typically generated at a single plant, then recirculated through a network of (insulated) pipes to the residential, commercial, and/or industrial buildings.

The buildings/apartments use the heat for both space heating and domestic hot water purposes.

By using a single source of heat that takes into account diversity across the network, district heating systems can help to reduce energy consumption, therefore lowering heating costs and minimising greenhouse gas emissions.

Source: CIBSE CP1 Heat Networks

How is a District Heating System Different from Traditional Heating Systems?

As mentioned above, a district heating system is a centralised heating network that provides heat to multiple buildings/apartments from a single source.

In contrast, traditional heating systems rely on individual heat sources installed in each building/apartment.

Traditional systems are typically less energy-efficient as each heat source operates independently and can not benefit from diversifying their load.

Consequently, traditional systems have higher fuel consumption and therefore higher energy bills and carbon emissions.

How Does District Heating Work?

There are four key parts to a district heating system:

- Heat Generation:

- The heat for a district heating system can be generated through various means, including fossil fuels, biomass, heat pumps, waste heat from industrial processes, and many other means.

- The choice of energy source depends on the project budget, available options, and the sustainability goals of the community.

- Heat Distribution:

- The heated fluid is supplied through a network of insulated pipes from the central plant to individual buildings/apartments.

- Heat Interface Unit (Heat Exchanger):

- As the heated fluid reaches a building/apartment, it passes through another heat exchanger (known as a heat interface unit), transferring heat to the heating and domestic hot water system separately.

- Heat Recirculation

- The cooled fluid, on the outlet of the heat interface unit, returns to the central plant to be reheated and redistributed.

The image below shows the district heating pipes (red and cyan) connecting to heat interface units, which then supply the space heating (red and cyan) and domestic hot water (orange) to each apartment.

Source: CIBSE Ireland

What are the Benefits of District Heating

There are four key benefits to a district heating system:

- Energy Efficiency:

- Due to the high number of buildings/apartments connected, efficiency can be gained through applying diversity to the system .

- Cost Savings:

-

By consolidating heat generation for multiple buildings, district heating systems can reduce infrastructure and maintenance costs, leading to lower heating bills for consumers.

-

- Environmental Impact:

- Utilising renewable energy sources or waste heat can minimise greenhouse gas emissions.

- Flexibility:

- District heating systems can adapt to different energy sources and technologies, making them a future-proof solution as communities transition to renewable energy.

What are the Limitations of District Heating?

Limitations of district heating systems include:

- High initial investment costs

- Heat losses in the distribution network

- The complexity of retrofitting existing buildings.

The limitations of a district heating system are amplified as the distance between the energy center and the buildings/apartments becomes greater.

Is District Heating Renewable?

The renewable potential of a district heating system depends on the energy sources used for heat generation.

When powered by renewable energy sources like heat pumps, solar, geothermal, or biomass, district heating can be considered an eco-friendly and sustainable solution.

Additionally, using waste heat from industrial processes can significantly reduce the environmental impact of these systems.

However, it is possible to use fossil fuels for heat generation, which reduces the sustainability benefits of the system.

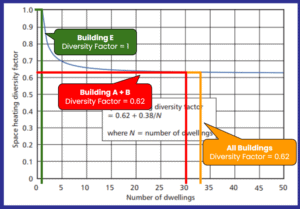

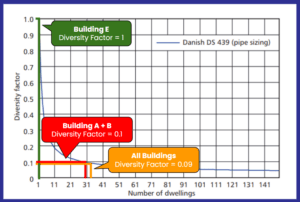

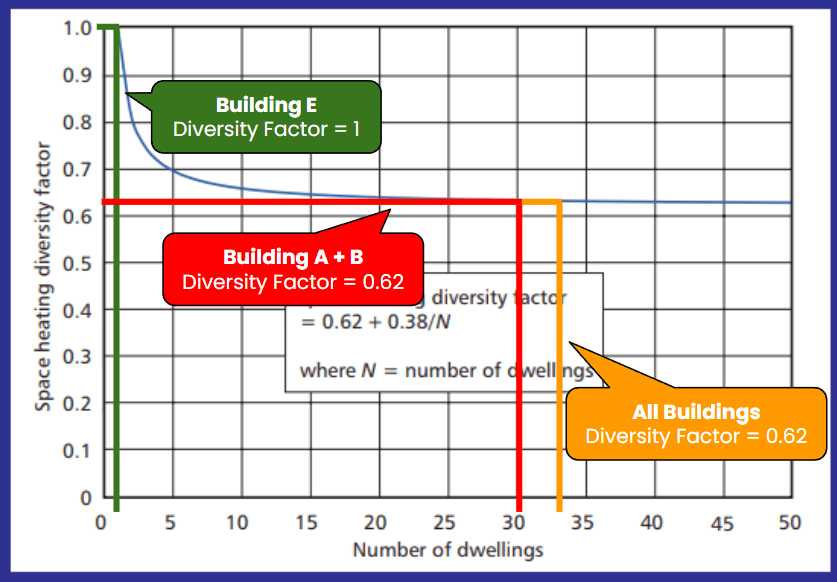

Diversity in a District Heating System

In large heating systems, accounting for diversity is crucial for designing an efficient and effective network.

Understanding and incorporating diversity into system design ensures that the infrastructure meets the system demands while minimising energy waste.

The CIBSE CP1 Heat Networks guidelines provide standardised diversity factors for both heating load and domestic hot water load.

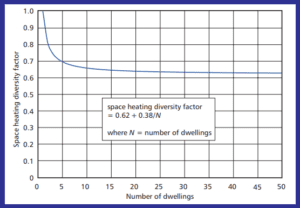

District Heating Diversity for Heating

Source: CIBSE CP1 Heat Networks

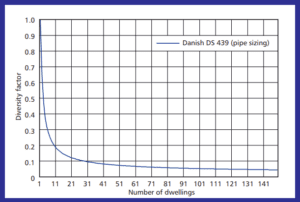

District Heating Diversity for Domestic Hot Water

Source: CIBSE CP1 Heat Networks

By applying these diversity factors, engineers can create a more efficient and effective heating network tailored to reflect the reality that not all buildings will experience peak demand simultaneously.

Design and Calculation Example of a District Heating System

Designing an efficient heating district system involves a series of calculations and considerations to ensure optimal performance.

We will walk you through a hypothetical design and calculation process to help you understand the details of creating a district heating system.

This step-by-step approach includes essential factors such as delta T, diversity, and recirculation, to help you learn how to design an efficient system.

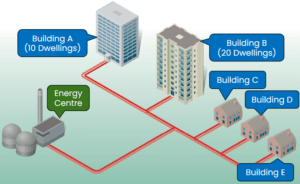

Step 1: Draw Your Layout

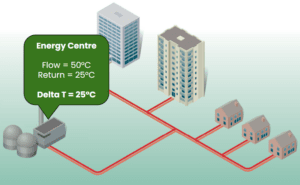

Let’s begin by sketching a layout of the district heating system.

We have the energy centre (central plant) and five buildings (some with multiple dwellings) that we need to supply with heat.

Step 2: Choose Your Delta T

You need to choose an appropriate temperature difference (delta T) between the supply and return pipes.

CIBSE CP1 Heat Networks provides a range of temperatures and delta Ts for the various generations of systems.

A typical delta T value for district heating systems is around 20°C to 30°C (68°F to 86°F).

In our example, we will use a delta T of 25°C.

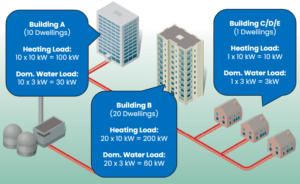

Step 3: Perform Heat Load Calculations

Calculate separate heat loads for the heating and domestic hot water systems in each building:

To learn how to do the heat load calculations in detail, refer to our Heat Pump eBook.

For simplicity in this article, we will use some assumptions.

- Heating load:

- Let’s assume a heating load of 10 kW per dwelling.

- Domestic hot water load:

- Let’s assume a hot water demand of 3 kW per dwelling.

Step 4: Calculate the Total Load on Each Section of Pipe

Sum the total heat loads for both the heating and domestic hot water systems on each pipe segment.

We will focus on three areas in this example, rather than every single pipe segment.

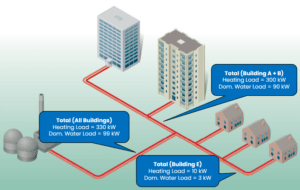

Step 5: Determine Diversified Heat Load Using CIBSE CP1 Diversity Factors

For the three pipe segments in this example, we will need to apply CIBSE CP1 Heat Networks diversity factors.

District Heating Diversity for Heating

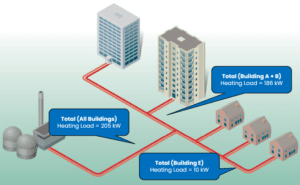

All Buildings

Heating Load: 330 kW

Diversity Factor: 0.62

Diversified Load: 205 kW

Building A + B

Heating Load: 300 kW

Diversity Factor: 0.62

Diversified Load: 186kW

Building E

Heating Load: 10 kW

Diversity Factor: 1

Diversified Load: 10 kW

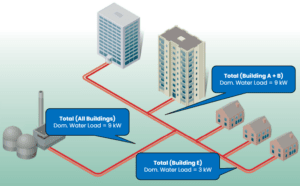

District Heating Diversity for Domestic Hot Water

All Buildings

Heating Load: 99 kW

Diversity Factor: 0.09

Diversified Load: 9 kW

Building A + B

Heating Load: 90 kW

Diversity Factor: 0.1

Diversified Load: 9 kW

Building E

Heating Load: 3 kW

Diversity Factor: 1

Diversified Load: 3 kW

Step 6: Calculate the Flow Rate Through the Pipes

After calculating the kW load on each pipe, we can now calculate the flow rates.

The formula we use for this is:

Flow rate (L/s) = Diversified heat load (kW) / (Specific heat capacity (kJ/kg°C) x delta T (°C))

Now let’s use this formula for the three pipe segments.

All Buildings

Diversified Heating Load: 205 kW

Diversified Domestic Hot Water Load: 9 kW

Total Diversified Load: 214 kW

Flow rate = 214 kW / (4.05 kJ/kg°C x 25°C)

Flow rate = 214 kW / 101.25

Flow rate = 2.11 L/s

Building A + B

Diversified Heating Load: 186 kW

Diversified Domestic Hot Water Load: 9 kW

Total Diversified Load: 195 kW

Flow rate = 195 kW / (4.05 kJ/kg°C x 25°C)

Flow rate = 195 kW / 101.25

Flow rate = 1.93 L/s

Building E

Diversified Heating Load: 10 kW

Diversified Domestic Hot Water Load: 3 kW

Total Diversified Load: 13 kW

Flow rate = 13 kW / (4.05 kJ/kg°C x 25°C)

Flow rate = 13 kW / 101.25

Flow rate = 0.13 L/s

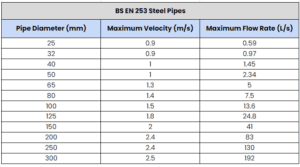

Step 7: Size the Pipes

CIBSE recommend that you size the district heating pipes based on a maximum velocity.

The maximum velocity limit changes based on the pipe material and size.

An overview of their recommendations is shown in the table below:

Try our free pipe velocity calculator for your next velocity calculations.

Based on the table, we can size the pipes for each pipe segment.

All Buildings

Flow rate = 2.11 L/s

Pipe Size = 50 mm

Building A + B

Flow rate = 1.93 L/s

Pipe Size = 50 mm

Building E

Flow rate = 0.13 L/s

Pipe Size = 25 mm

To learn how to do pipe sizing calculations in more detail, refer to our Heat Pump eBook.

Step 8: Calculate Recirculation Pump Duty

The final step in the design is to determine the recirculation pump duty.

The recirculation pump duty is sized based on:

- The total diversified flow rate:

- 2.11 L/s (as calculated above)

- The pressure drop through the index circuit:

- The index circuit is the section of the pipe network with the highest pressure loss, which is typically the furthest pipe route from the heat source

- The pressure loss will take into account the friction loss through all pipes, valves, fittings, and any other components

To learn how to do detailed pressure drop calculations in more detail, refer to our Heat Pump eBook.

You can also try our free pressure drop calculator.

Conclusion

District heating systems are an innovative and efficient approach to meeting the heating demands of communities.

By centralizing heat generation and using renewable energy sources, these systems can contribute to a more sustainable and environmentally friendly future.

As global efforts continue to focus on reducing carbon emissions and promoting renewable energy, district heating systems will undoubtedly play a crucial role in achieving these goals.

In h2x, you can design a District Heating system and get accurate, detailed calculations inclusive of the CIBSE CP1 Heat Networks diversity.

Learn more by watching the short video below:

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry standards.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start your free trial today to discover how h2x can help you improve your design and calculation workflow.

District Heating FAQs

What is a district heating system?

A district heating system is a centralized heating network that provides heat and hot water to multiple buildings or apartments from a single energy centre.

District heating systems offer improved energy efficiency, lower carbon emissions, and reduced maintenance requirements compared to individual heating solutions.

Why is diversity important in district heating systems?

Diversity is essential in district heating systems because it accounts for variations in heating demand among connected buildings.

By incorporating diversity factors, engineers can optimise system capacity, ensure that the network operates effectively during peak demand periods, and minimise energy waste.

What are CIBSE CP1 Heat Networks diversity factors?

CIBSE CP1 Heat Networks diversity factors are standardized percentages provided by the Chartered Institution of Building Services Engineers (CIBSE) to help engineers account for variations in heating and domestic hot water demand among connected buildings.

These factors enable more accurate heat load calculations and ensure efficient system design.

You can find the diversity tables earlier in this blog.

How do I apply CIBSE CP1 diversity factors to my district heating system design?

To apply CIBSE CP1 diversity factors, first calculate the heating and domestic hot water loads for each pipe segment and connected buildings.

Then, consult the CIBSE CP1 Heat Networks guidelines to determine the appropriate diversity factors.

The diversified heat loads can be used for system design and planning.

Can diversity factors be applied to both heating and domestic hot water loads?

Yes, CIBSE CP1 Heat Networks diversity factors can be applied to both heating and domestic hot water loads.

This ensures that the district heating system is designed to handle the varying demands of both types of loads, improving overall system efficiency and performance.

There are separate diversity factors for the heating and domestic hot water loads, so they are calculated separately and then added together.

Are there any other factors to consider when designing a district heating system?

In addition to diversity, other factors to consider when designing a district heating system include pipe sizing, insulation, pump selection, and control strategies.

It is also essential to account for local regulations, environmental factors, and any potential future expansions when planning your district heating network.

Where is district heating common?

District heating is common in countries with cold climates and high population density, particularly in Europe.

Examples include Denmark, Sweden, Finland, Germany, and the Netherlands.

It is also gaining popularity in countries like the UK, China, and Canada, as they strive to improve energy efficiency and reduce carbon emissions.

Are there different types/generations of district heating?

- 1st Generation:

- Steam-based systems operating at high temperatures and pressures, primarily using fossil fuels as their heat source.

- These systems were less efficient and environmentally friendly.

- 2nd Generation:

- Pressurized hot water systems with temperatures between 120°C and 150°C, which improved efficiency compared to the steam-based systems.

- These systems still primarily relied on fossil fuels as the primary heat source.

- 3rd Generation:

- Lower temperature hot water systems (80°C to 120°C), which are more energy-efficient and compatible with renewable energy sources.

- The focus of these systems is on reducing heat losses in the distribution network, utilising combined heat and power (CHP) plants, and integrating renewable energy sources.

- 4th Generation:

- Ultra-low temperature systems (below 80°C) that prioritise energy efficiency, integration of renewable energy sources, and smart grid technology.

- These systems aim to achieve low carbon emissions, higher efficiency, and improved flexibility in the heating network.

- 5th Generation:

- This potential future generation of district heating systems would focus on using ambient or low-grade heat sources and advanced heat pump technology to further reduce energy consumption and carbon emissions.

- The concept envisions a fully integrated and flexible energy system, which would enable the exchange of heat, cooling, and electricity between buildings, thus enhancing overall efficiency and sustainability.

Metering in district heating systems

Metering in district heating systems involves measuring the heat energy consumption of individual buildings or apartments connected to the network.

Accurate metering ensures fair billing for users, encourages energy conservation, and helps identify system inefficiencies or issues.

Modern district heating systems use smart meters that enable remote monitoring, real-time data collection, and integration with automated billing systems.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP