h2x Tools

Pressure Drop Calculator

Learn everything about pressure drop, understand the Darcy Weisbach formula, and use our free online calculator.

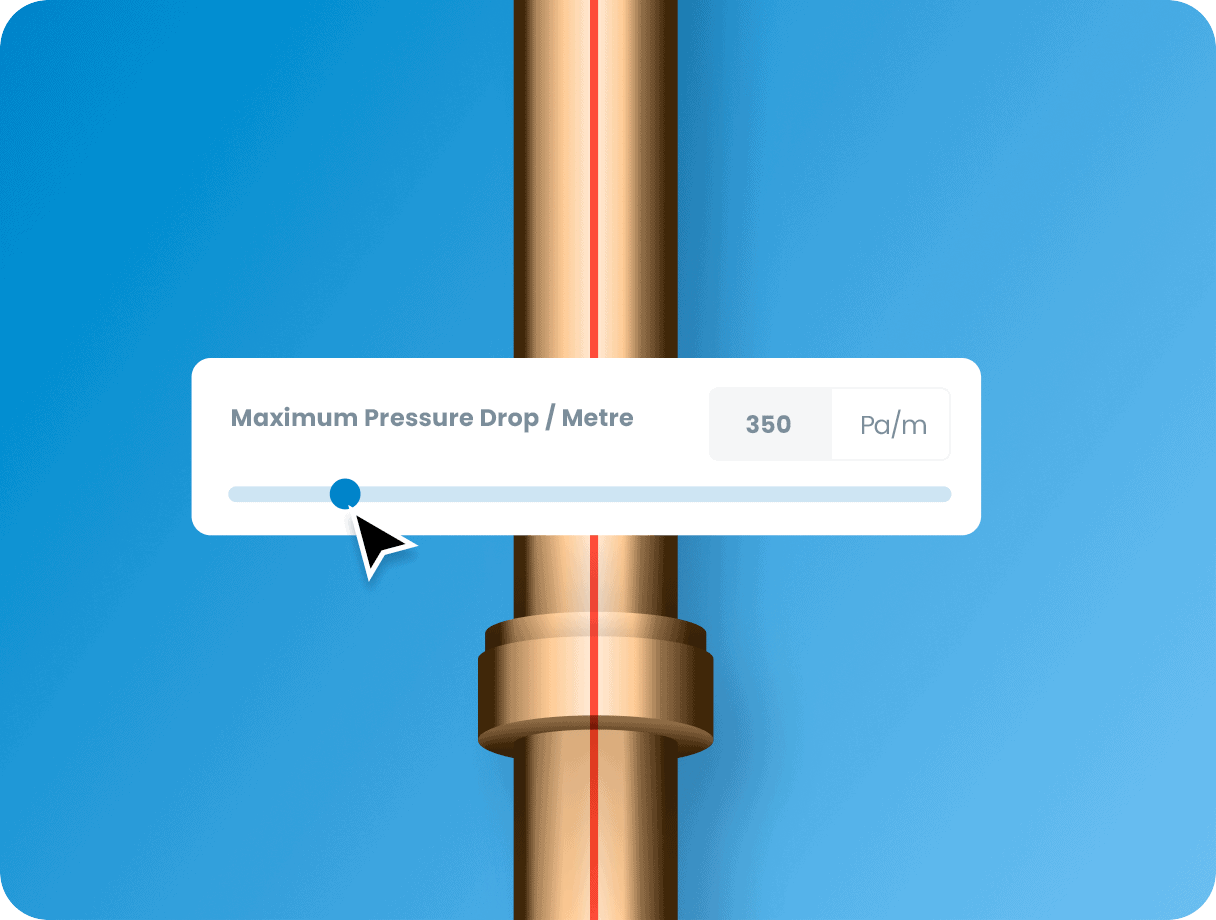

Get accurate results across the pipe length with this simple, yet powerful online calculator.

Enter fields below to get your results

Other Users Found These Online Calculators Useful

Calculate velocity through a pipe quickly and easily, eliminating the need to perform complex mathematical calculations manually.

Choose from a range of international standards, add fixtures, and automatically receive the peak flow rate calculation.

Find out how much water volume is in your pipe by simply inputting the pipe diameter (pipe d) and the pipe length (pipe l).

Variables:

Factors Affecting Pressure Drop

Pipe Details

The pipe roughness and pipe length (pipe l) will result in a higher pressure drop, while the opposite will result in a lower pressure drop.

Fluid Details

A more viscous and higher-velocity (flow rate) fluid will result in a higher pressure drop, while the opposite will result in a lower pressure drop.

Pressure Drop Formula

As the calculation can be measured in terms of ft/second and m/second, there are two different calculation methods to establish pressure drop:

Imperial Equation

The following equation can be used to calculate the pressure drop:

Components

- = Head loss in a pipe (ft)

- = Pipe length (ft)

- = Velocity of the fluid flow rate inside the pipe (ft/second)

- = Pipe internal diameter (ft)

- = Pipe roughness / Pipe friction factor {f = [1.14 + 2 log10(D/e)]-2} and then iteratively f = {-2*log10[((e/D)/3.7)+(2.51/(Re*(f1/2))]}-2

- = Gravity (ft/second2) , which has a constant value of approximately 32.2 ft/s2.

Metric Equation

The following equation can be used to calculate the pressure drop:

Components

- = Head loss in a pipe (m)

- = Pipe length (m)

- = Velocity of the fluid flow rate inside the pipe (m/second)

- = Pipe internal diameter (m)

- = Pipe roughness / Pipe friction factor {f = [1.14 + 2 log10(D/e)]-2} and then iteratively f = {-2*log10[((e/D)/3.7)+(2.51/(Re*(f1/2))]}-2

- = Gravity (m/second2) , which has a constant value of approximately 9.8 m/s2.

What is the Pressure Drop Calculation Used For?

Pressure drop is a critical aspect in various industries, including oil and gas, HVAC, plumbing, and many others.

It refers to the pressure loss as fluid or gas moves through a pipe.

Pressure drop calculations are crucial for ensuring efficient operation and preventing damage to equipment. Whether you're dealing with laminar or turbulent flow, our online calculator provides accurate results.

With advancements in technology, pressure drop calculations have become much easier with a pressure drop online calculator.

Whether you're a seasoned professional or just starting, this guide will give you a comprehensive understanding of pressure drop, its calculations, and how our online calculator can help.

h2x for Pressure Drop Calculations

- Calculates the pressure drop through every pipe (CIBSE-verified)

- Calculates the pressure drop through every valve and fitting (CIBSE-verified)

- Automates all of the calculations based on your design layout

h2x is CIBSE-verified design software built to improve the efficiency and quality of your design process. Read more.

Why Use a Pressure Drop Calculator?

There are several benefits of using our online calculator for Pressure Drop, including:

Increased Accuracy:

Provides accurate results, eliminating the possibility of human error when calculating fluid pressure drop by hand.

Time-Saving:

Saves time by providing quick and easy calculations, eliminating the need to perform complex mathematical calculations manually.

Easy to Use:

User-friendly and requires no special training or technical knowledge. Just provide the input and receive detailed results.

Cost-Effective:

Can save money by reducing the time spent on manual calculations and avoiding costly mistakes.