How to Design a Hot Water Recirculation System

Designing a hot water recirculation system can be one of the most challenging parts of the job for many engineers. When done correctly, the process can involve numerous iterations of calculations between pipe sizing and heat loss before the final results are realised.

Designing a hot water recirculation system can be one of the most challenging parts of the job for many engineers. When done correctly, the process can involve numerous iterations of calculations between pipe sizing and heat loss before the final results are realised.

This video demonstrates how simple it is to design a hot water recirculation system using h2x, and includes the following;

- How to Set Calculation Parameters

- Insulation type and thickness

- Maximum velocities

- Pipe materials

- Delta T between flow and return

- How to Add Hot Water Plant

- How to Draw Pipes and Set Pipe Heights

- How to Connect Fixtures and Valves

- Calculation Results

- Return system duty flow rate

- Return system pressure loss

- Return system heat loss

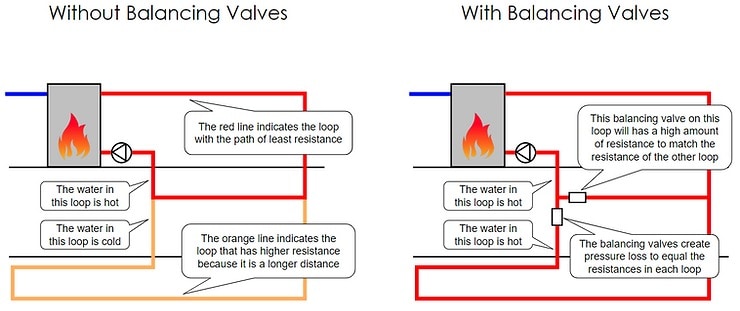

- Balancing valve Kv value

- Pipe peak flow rate

- Pipe return flow rate

- Pipe diameter

- Pipe velocity

- Pipe loading units

- Fixture static pressure

- Fixture dynamic pressure

- Fixture Dead Legs

Tip - Press the box in the bottom right-hand corner of the video to go full screen!

If you'd like to learn more technical details about Hot Water System design, why not check out our blog post at the link below.

6 steps you must consider before designing your next hot water system

Seen enough and would like to give H2X a try?

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP