Understanding Thermal Bridging and Its Impact on Building Heat Loss

Learn how thermal bridging affects heat loss in buildings. Explore solutions and insights to improve energy efficiency.

What is Thermal Bridging

As engineers and architects strive to create energy-efficient buildings, the importance of accounting for thermal bridging within our structures cannot be overstated.

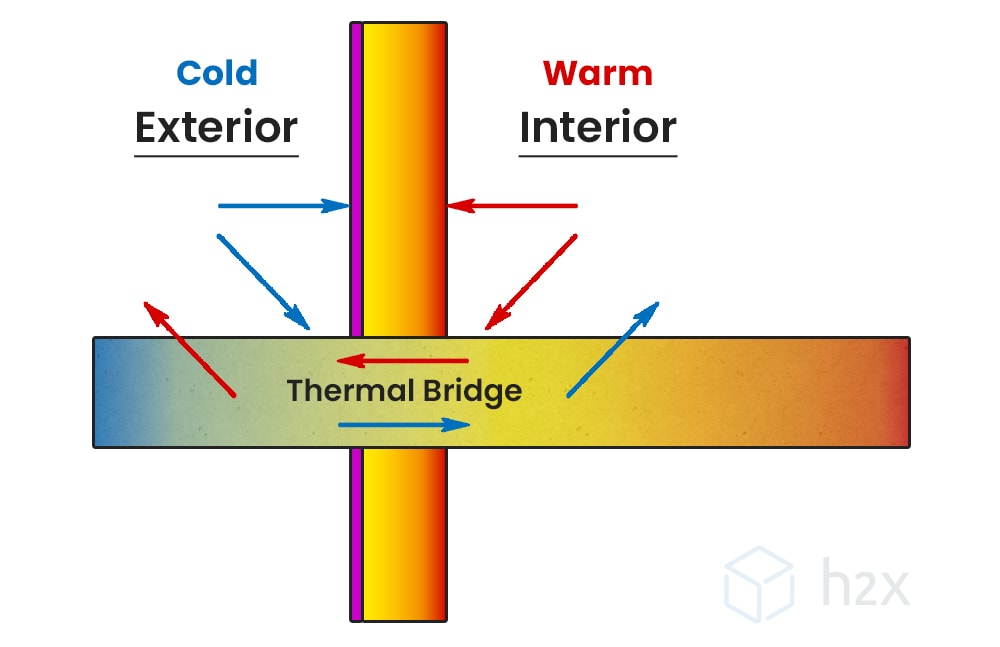

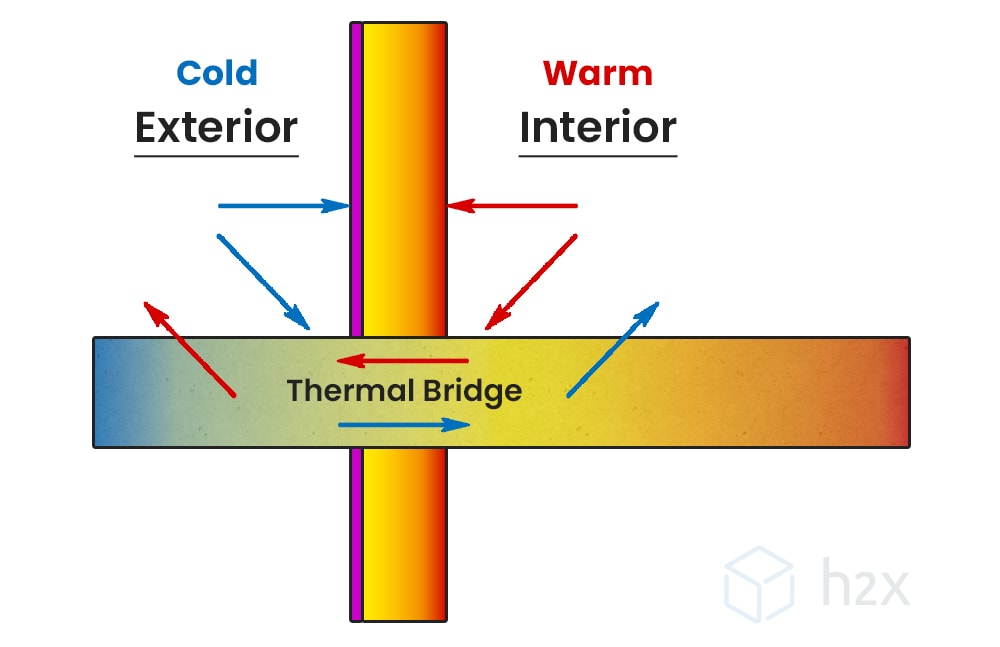

Thermal bridging, a major contributor to heat loss, occurs when a more conductive (or less insulative) material allows an easy pathway for heat flow across a thermal barrier.

This phenomenon significantly impacts building energy performance, potentially leading to more energy consumption, increased costs, and less comfort for occupants.

Where does thermal bridging occur?

Thermal bridging is typically found at various points within a building envelope, each offering distinct challenges:

1. Wall Studs: Metallic or wooden studs used for structural support in walls can interrupt the insulation continuity, providing a direct pathway for heat transfer.

2. Junctions between Wall and Floor/Ceiling: These junctions can often lead to insulation gaps, leading to thermal bridges and subsequent heat loss.

3. Fenestration: Doors and windows often provide less insulation than walls, creating thermal bridges, particularly around frames and sashes.

4. Roof and Ceiling Joists: These structural elements can disrupt the insulation layer similar to wall studs, becoming conduits for heat flow.

5. Balconies and Parapets: When these elements are constructed from highly conductive materials without proper insulation, they can form significant thermal bridges.

6. Utility Penetrations: Any breach in the building envelope for utilities, like pipes, wires, or ducts, can interrupt the insulation layer and create thermal bridges.

Quantifying the Impact of Thermal Bridging

The overall impact of thermal bridging on a building’s heat loss is substantial.

Rough estimates suggest:

- Wall studs can increase the total heat loss by 15-20%.

- Junctions, balconies, and parapets can add another 5-10% of heat loss.

- Fenestrations can account for up to 25% heat loss.

- Roof joists and utility penetrations can contribute an additional 2-5% heat loss.

These percentages can vary based on the specifics of the building design and the materials used.

How to Avoid Thermal Bridging

There are multiple strategies for mitigating thermal bridging, including:

1. Structural Design: Use a design that minimises the number of thermal bridges in the structure, such as continuous insulation or advanced framing techniques.

2. Material Selection: Select materials with lower thermal conductivity for components that may cause thermal bridges.

3. Thermal Breaks: Include thermal breaks, less conductive materials interrupting the heat flow path.

4. Enhanced Insulation: Increase the insulation level in areas where thermal bridging is unavoidable.

Understanding and properly addressing thermal bridging is key to designing and building energy-efficient structures.

By implementing careful design strategies, material selection, and advanced energy modelling techniques, we can significantly reduce the impact of thermal bridging on our buildings and create more comfortable, cost-effective, and sustainable environments.

The Importance in Building Energy Calculations

Including thermal bridging in your building energy calculations is vital for accurately understanding overall building performance.

By neglecting to account for thermal bridges, you risk underestimating the heat loss within a building, which can result in overestimating the building’s energy efficiency.

This could subsequently lead to inefficient use of heating or cooling systems, higher energy costs, and discomfort for the building’s occupants.

Thermal bridges can introduce significant heat flows that aren’t included in the U-values of individual building elements, which are usually calculated under the assumption of one-dimensional heat transfer.

By accounting for thermal bridges, we can better estimate the real-world, multi-dimensional heat transfer that occurs within buildings, thus producing more accurate energy performance calculations.

Moreover, ignoring thermal bridges might make certain energy-saving measures seem more effective in calculations than they would be in practice.

For example, if you’re considering adding more insulation to a wall, neglecting the thermal bridges caused by the wall studs could overestimate the energy savings this measure would achieve.

Including thermal bridging in your calculations will therefore lead to a more realistic understanding of a building’s energy performance and a better basis for decision-making about energy-saving measures.

It’s key to achieving genuinely efficient, sustainable buildings and should not be overlooked in any detailed building energy assessment.

Conclusion

Thermal bridging significantly contributes to heat loss and greatly impacts a building’s energy efficiency.

It occurs at various points within a building where there is a discontinuity in insulation, allowing heat to escape more readily.

By factoring in thermal bridging into our energy calculations, we can better understand a building’s energy performance, leading to more effective energy-saving measures, lower energy costs, and greater comfort for occupants.

Mitigation strategies, like thoughtful structural design, careful material selection, including thermal breaks, and enhanced insulation, can combat thermal bridging.

By prioritising these strategies, we can create more energy-efficient, sustainable buildings.

Empower your engineering endeavors with h2x’s cutting-edge Heat Loss Calculation Software, providing accurate calculations to optimise thermal efficiency in building designs.

Harness the power of h2x’s MCS-aligned heat loss tool to elevate the efficiency and precision of your heat loss calculations and heating system designs.

Simplify your projects and elevate energy performance effortlessly through the utilisation of our state-of-the-art tool.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

FAQs

What is thermal bridging?

Thermal bridging refers to the phenomenon where a more conductive (or less insulative) material provides a direct path for heat transfer across a thermal barrier, such as the insulating layer in a wall, floor, or roof.

What is a thermal bridge?

A thermal bridge is a specific point or component in a building where thermal bridging occurs. This could be a structural element like a metal stud in a wall, a concrete floor slab, or a window frame, among other things.

How to avoid thermal bridging?

Thermal bridging can be avoided through careful design and construction practices, such as:

- Using continuous insulation across the entire building envelope.

- Minimising the use of thermally conductive materials that penetrate the insulation layer.

- Designing junctions and transitions in the building envelope to minimise heat loss.

How to fix thermal bridging?

Fixing thermal bridging in existing buildings can be more challenging but possible solutions include:

- Adding insulation to the outside of the building envelope to cover thermal bridges.

- Replacing windows or doors with more energy-efficient models.

- Using thermal imaging to identify and then specifically address major thermal bridges.

How to prevent thermal bridging?

Preventing thermal bridging involves designing and constructing the building to minimise the potential for thermal bridges. This might involve using specific construction techniques such as:

- Advanced framing techniques that reduce the number of studs in walls.

- Using insulated window and door frames.

- Designing junctions to reduce heat loss.

How to prevent thermal bridging in walls?

To prevent thermal bridging in walls, you can use continuous insulation, minimise the number of structural elements that penetrate the insulation layer, or use insulated sheathing. Advanced framing techniques can also be beneficial.

How to reduce thermal bridging?

Reducing thermal bridging can be achieved by incorporating thermal breaks into the design of the building, using materials with low thermal conductivity, and ensuring that the insulation is continuous and properly installed.

How to reduce thermal bridging around windows?

To reduce thermal bridging around windows, you can use insulated window frames, ensure the window is properly installed and sealed, and consider using a continuous layer of insulation around the window frame.

How to stop thermal bridging?

While it may not be possible to completely eliminate all thermal bridging, it can be significantly reduced through the abovementioned strategies: careful design, use of materials with low thermal conductivity, and continuous insulation.

How to stop thermal bridging through rafters?

To reduce thermal bridging through rafters, you can install insulation between the rafters and across them, creating a continuous insulating layer. This is often done using rigid foam insulation or insulating sheathing. The details will depend on the specifics of the roof construction.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP