Hazen-Williams vs. Darcy-Weisbach

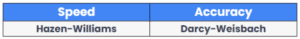

The Hazen-Williams and Darcy-Weisbach equations have their merits and limitations, mainly relating to their ease of use and accuracy.

Hazen-Williams vs. Darcy-Weisbach Introduction

When it comes to designing and analysing fluid flow in pipes, the Hazen-Williams and Darcy-Weisbach equations are two essential tools engineers rely upon.

This article will provide an in-depth comparison of the Hazen-Williams vs. Darcy-Weisbach equations, discussing their advantages, disadvantages, and differences to help you determine which method is most suitable for your needs.

Hazen-Williams

The Hazen-Williams equation is commonly used for water flow through pipes.

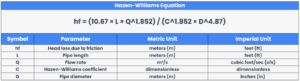

Hazen-Williams Equation

The Hazen-Williams equation is as follows:

hf = (10.67 × L × Q^1.852) / (C^1.852 × D^4.87)

Where:

- hf is the head loss due to friction (m)

- L is the pipe length (m)

- Q is the flow rate (m³/s)

- C is the Hazen-Williams coefficient (dimensionless)

- D is the internal pipe diameter (m)

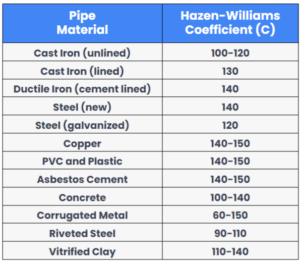

Hazen-Williams Roughness Coefficient

The Hazen-Williams roughness coefficient (C) represents the relative roughness of the interior surface of a pipe.

It is a dimensionless empirical value used in the Hazen-Williams equation to account for the effect of pipe material on flow resistance.

Higher values of the Hazen-Williams coefficient indicate smoother pipes, which generally result in lower head losses.

Here are some common Hazen-Williams roughness coefficients for various pipe materials:

- Cast Iron (unlined): 100-120

- Cast Iron (lined): 130

- Ductile Iron (cement lined): 140

- Steel (new): 140

- Steel (galvanized): 120

- Copper: 140-150

- PVC and Plastic: 140-150

- Asbestos Cement: 140-150

- Concrete: 100-140

- Corrugated Metal: 60-150

- Riveted Steel: 90-110

- Vitrified Clay: 110-140

Advantages

The advantages of the Hazen-Williams formula are:

- Simplicity: The Hazen-Williams equation is easier to use than the Darcy-Weisbach equation, as it doesn’t require iterative calculations.

- Easy: It estimates friction loss in a pipeline with just a few parameters.

Disadvantages

The disadvantages of the Hazen-Williams formula are:

- Limited: This equation is only applicable to water flow and cannot be used for other fluids.

- Inaccurate: It is less accurate for larger pipes and higher flow velocities.

Darcy-Weisbach

The Darcy-Weisbach equation is a more versatile and accurate method for calculating head loss due to friction in fluid flow.

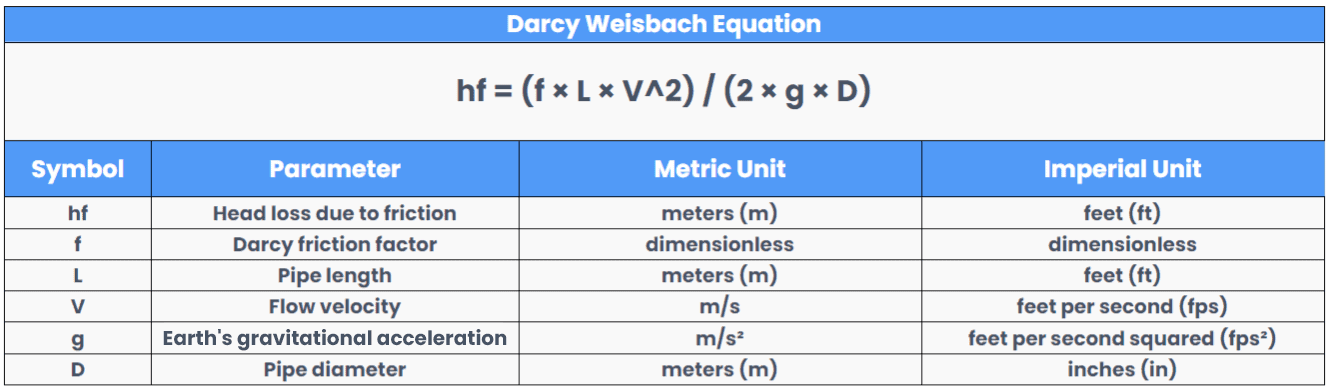

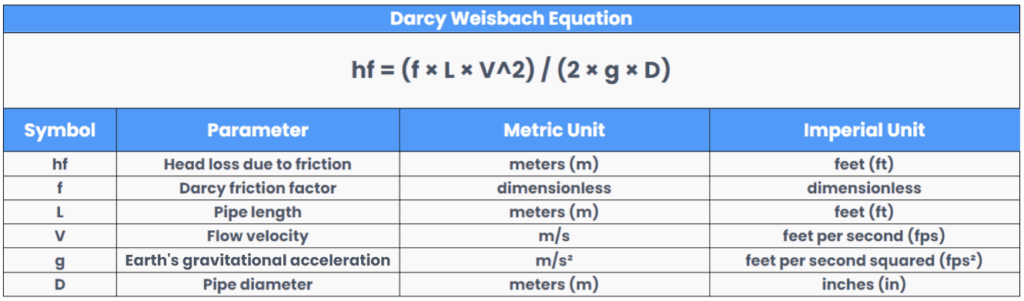

Darcy-Weisbach Equation

The Darcy-Weisbach equation is as follows:

hf = (f × L × V^2) / (2 × g × D)

Where:

- hf is the head loss due to friction

- f is the Darcy friction factor

- L is the pipe length

- V is the flow velocity

- g is the earth’s gravitational acceleration

- D is the internal pipe diameter

Advantages

The advantages of the Darcy-Weisbach formula are:

- Versatility: The Darcy-Weisbach equation can be used for various fluids, not just water.

- Accuracy: It provides more accurate results for a wide range of pipe sizes and flow velocities.

Disadvantages

The disadvantages of the Darcy-Weisbach formula are:

- Complexity: The equation is more complex, requiring iterative calculations and additional parameters.

- Friction Factor: The user must determine the Darcy friction factor, which can be challenging to estimate accurately.

Hazen-Williams vs. Darcy-Weisbach Comparison

Accuracy

While the Hazen-Williams equation is more straightforward, it sacrifices accuracy, especially for larger pipes, higher flow velocities, and a range of temperatures.

The Darcy-Weisbach equation offers higher accuracy across a broader range of applications.

Range of Applications

The Hazen-Williams equation is limited, while the Darcy-Weisbach equation can be applied to various scenarios, making it more versatile and suitable for a wide range of industries and applications.

Ease of Use

The Hazen-Williams equation is easier to use due to its simplicity and fewer required parameters.

However, the Darcy-Weisbach equation, although more complex, provides more accurate and comprehensive results.

Calculation Example

Let’s perform a comparison calculation for the Hazen-Williams and Darcy-Weisbach equations using the following parameters:

- Flow Rate (Q): 0.05 cubic meters per second (m³/s)

- Pipe Material: Copper

- Hazen-Williams Coefficient (C): 140

- Darcy-Weisbach Coefficient (ε): 0.0015 mm

- Pipe Length (L): 500 meters

- Internal Pipe Diameter (D): 0.15 meters (150 mm)

- Fluid temperature: 20°C

- Fluid density (ρ): 1000 kg/m³

- Dynamic viscosity (μ): 1.004 × 10^-3

Hazen-Williams Equation

- hf = (10.67 × L × Q^1.852) / (C^1.852 × D^4.87)

- hf = (10.67 × 500 × (0.05)^1.852) / (140^1.852 × (0.15)^4.87)

- hf ≈ 23.12 meters head

Darcy-Weisbach Equation

First, we need to calculate the velocity:

- A = π × (D / 2)^2

- A = π × (0.15 / 2)^2 ≈ 0.0177 m²

- V = Q / A

- V = 0.05 / 0.0177 ≈ 2.82 m/s

Next, we need to calculate the Reynolds Number (Re):

- Re = (ρ × V × D) / μ

- Re = (1000 × 2.82 × 0.15) / (1.004 × 10^-3)

- Re ≈ 419566

And we also need to know the Friction Factor (f):

- 1 / √f = -2 × log10((ε / (3.7 × D)) + (2.51 × (ν × √f) / (D × V)))

- 1 / √f = -2 × log10((1.5 × 10^-6) / (3.7 × 0.15) + (2.51 × (1.004 × 10^-6 × √f) / (0.15 × 2.82)))

- Following an iterative process, we find that f ≈ 0.0137

Now we can undertake the Darcy-Weisbach Equation:

- hf = (f × L × V^2) / (2 × g × D)

- hf = (0.0137 × 500 × (2.82)^2) / (2 × 9.81 × 0.15)

- hf ≈ 17.47 meters

As you can see from the above examples, the Darcy Weisbach calculation is more detailed but takes more time to undertake.

Choosing the Right Equation for Your Needs

When deciding between the Hazen-Williams and Darcy-Weisbach equations, consider the following factors:

- Accuracy: For higher accuracy, especially in larger pipes and high flow velocities, the Darcy-Weisbach equation is the better choice.

- Ease of Use: If simplicity and ease of use are more critical for your application, the Hazen-Williams equation may be preferred.

The two formulas above are for pressure drop through pipes. For the pressure drop through valves, feel free to read our blog on Flow Coefficient.

Hazen-Williams vs. Darcy-Weisbach Conclusion

In conclusion, both the Hazen-Williams and Darcy-Weisbach equations have their merits and limitations.

The Hazen-Williams equation is simpler and easier to use but is limited in scope and accuracy.

The Darcy-Weisbach equation is more versatile and accurate but requires more complex calculations.

Ultimately, the choice between the two methods depends on the specific requirements of your project, fluid type, and desired level of accuracy.

Learn More

Want to learn more about friction loss with real-life examples?

Watch the 13-minute webinar below:

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The software provides automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems, allowing you to focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo with us today to discover how h2x can help you improve your design and calculation workflow.

FAQs

Is the Darcy-Weisbach equation suitable for all pipe materials?

Yes, the Darcy-Weisbach equation can be used for all pipe materials, as long as the appropriate friction factor is determined.

How do I determine the Darcy friction factor?

The Darcy friction factor can be determined using various methods, such as the Moody chart, Colebrook-White equation, or Swamee-Jain equation.

Try our free pressure drop calculator which will calculate the friction factor for you.

Why is the Hazen-Williams equation less accurate for larger pipes?

The Hazen-Williams equation becomes less accurate for larger pipes due to its empirical nature and simplifications made during its development.

Which equation is more widely used in industry?

Both equations are widely used in their respective fields.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP