UK – Domestic Mains Water Pipe Size Calculator

Welcome to this mains water pipe size calculator for the UK.

Download your free PDF of this article below.

Welcome to this mains water pipe size calculator for the UK.

Residential:

BS EN 806.3:2006

Commercial:

BS 8558:2015 (formerly BS6700)

CIPHE Design Guide (similar to CIBSE Guide G and an extension from the Institute of Plumbing)

Each pipe sizing method works by assigning loading units to individual fixtures. Fixtures that use higher volumes of water are generally assigned higher loading unit values.

As more loading units are connected to a pipe, the higher the peak flow rate becomes. This is because it is assumed that more fixtures are likely to operate simultaneously.

All three pipe sizing methods determine the ‘peak’ flow rate (the 99th percentile) using a conversion from loading units. However, each method has its own unique difference that is explained below.

BS EN 806.3:2006

This pipe sizing method is recommended to be used for residential building designs.

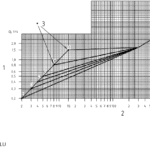

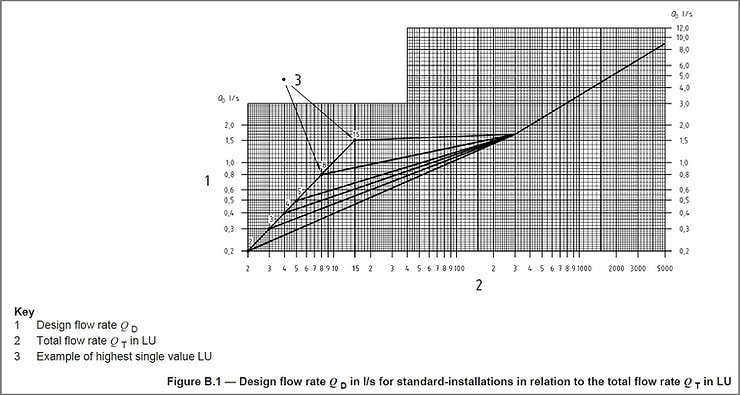

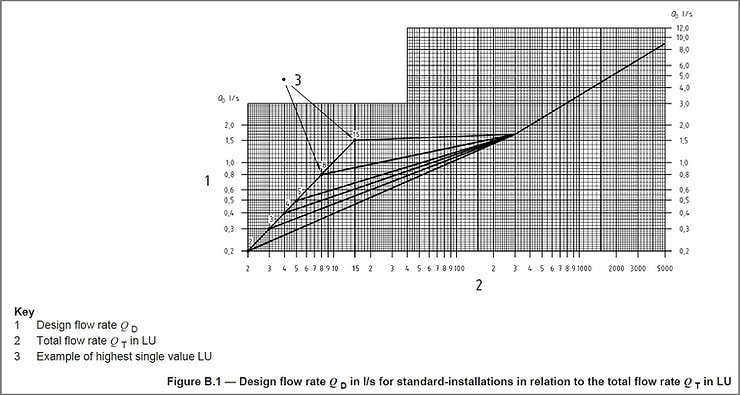

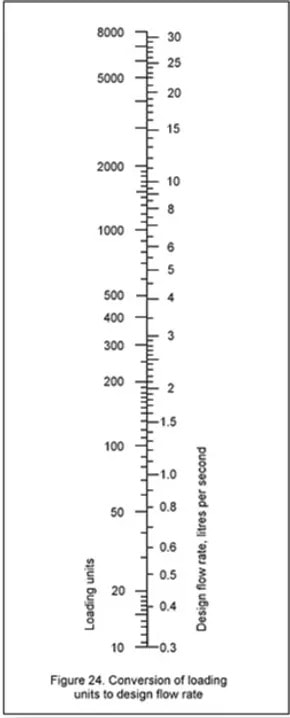

The conversion from loading units (2) to a flow rate (1) can be seen in the below chart.

What is unique about this method is that the fixture with the largest loading unit (3) plays an important part in the calculation.

For example:

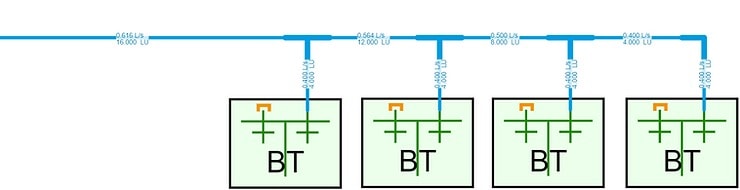

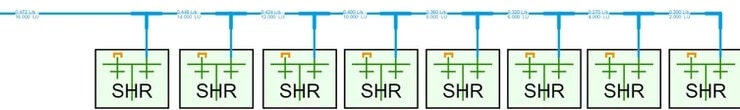

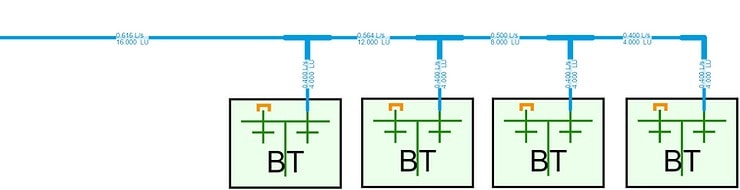

A pipe that is supplying four baths (4 loading units each) has 16 loading units.

A pipe that is supplying eight showers (2 loading units each) also has 16 loading units.

However, as you can see in the images above, the pipe that is supplying the 16 loading units has a different peak flow rate result.

When the largest loading unit connecting to the pipe is 4, the peak flow rate is 0.616 L/sec.

BS 8558:2015

This pipe sizing method is recommended to be used for commercial building designs.

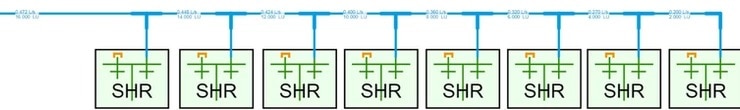

The conversion from loading units to a flow rate can be seen in the below chart.

This conversion is much simpler than BS EN 806.3:2006 because it does not factor in the largest fixture loading unit that is connected to the pipe.

This method generally provides higher flow rates than BS EN 806.3:2006 as it assumes the number of fixtures that could operate simultaneously in a commercial building is higher than in a residential building.

For example:

A pipe that is supplying four baths (10 loading units each) has 40 loading units which convert to a peak flow rate of 0.670 L/sec. This is higher than BS EN 806.3:2006.

A pipe that is supplying eight showers (3 loading units each) has 24 loading units which convert to a peak flow rate of 0.488 L/sec. This is higher than BS EN 806.3:2006.

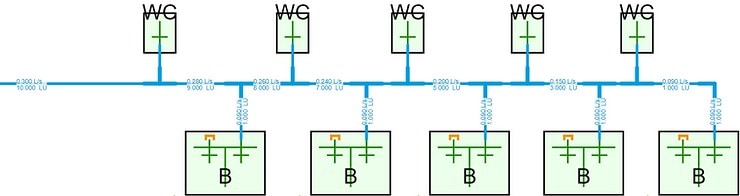

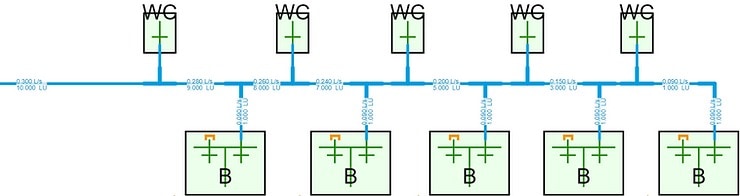

CIPHE Design Guide

This pipe sizing method is recommended to be used for commercial building designs and is an alternative to BS 8558:2015.

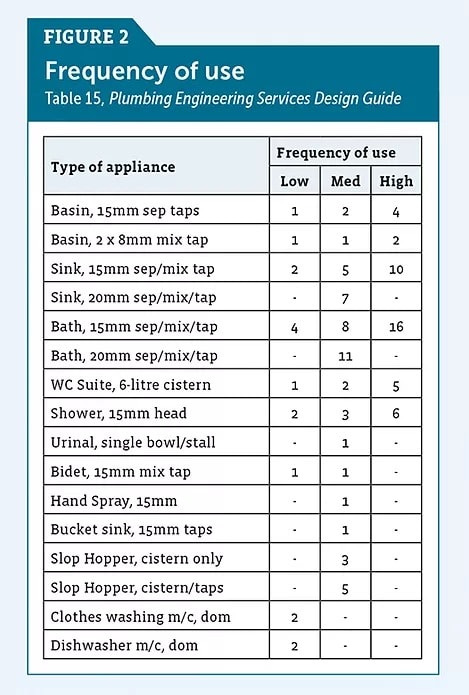

The conversion from loading units to a flow rate uses the same chart as BS 8558:2015. However, the key difference between the two methods is that the CIPHE Design Guide has options for the loading unit of each fixture based on how often the fixture is expected to be used.

As shown below, when the fixture’s frequency of usage gets lower, the loading units assigned to the fixture are lower too.

‘Low’ frequency = 20 minutes time difference between each use

‘Medium’ frequency = 10 minutes time difference between each use

‘High’ frequency = 5 minutes time difference between each use

Low frequency of use occurs where there is a single person or small group. High frequency of use occurs in buildings such as sports stadiums where there is a large group of people.

For example:

In a ‘low’ frequency of use building such as an office, a pipe that is supplying five basins (1 loading unit each) and five WCs (1 loading unit each) has 10 loading units which convert to a peak flow rate of 0.300 L/sec.

In a ‘high’ frequency of use building such as a stadium, a pipe that is supplying five basins (4 loading units each) and five WCs (5 loading units each) has 45 loading units which convert to a peak flow rate of 0.720 L/sec.

Additional Information to Consider for Mains Water Pipe Size Calculator

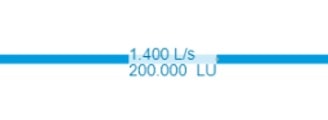

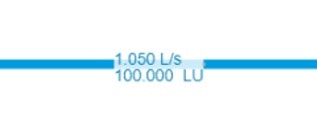

Combining Hot and Cold Water Loading Units

It is important to know whether the tapware that is used for each fixture will consist of two outlets (one for hot and one for cold) or one outlet (either hot or cold).

If the hot and cold water at a fixture can operate simultaneously, this will lead to an increased number of loading units on your pipe and consequently a higher flow rate.

For example:

Using the BS EN 806.3:2006 pipe sizing method, a pipe that supplies 100 basins that have a separate outlet for hot and cold water will convert to a flow rate of 1.40 L/sec.

If those 100 basins shared an outlet for hot and cold water, the loading units will be significantly less and will convert to a flow rate of 1.05 L/sec.

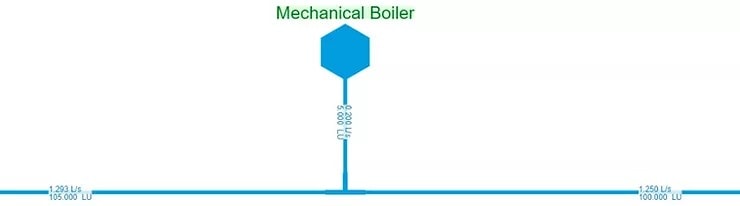

Other Water Requirements

When sizing pipes, it is important to consider more than the fixtures that are shown by the architect. There may be other water requirements on the project too such as mechanical boilers.

These items will not have loading units that are pre-defined because they are unique and project-specific.

To allow for these in your design, you will need to estimate a suitable load to assign to them based on their technical requirements.

For example:

Using the BS 8558:2015 pipe sizing method, a pipe that supplies 100 loading units will convert to 1.25 L/sec.

If you estimate the load from the mechanical boilers is equivalent to 5 loading units, the load will be allowed for in the upstream pipe and the flow rate is therefore increased to 1.293 L/sec.

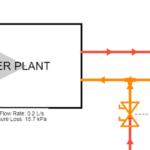

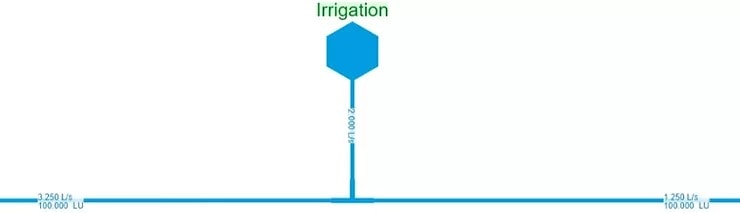

Continuous Flow Rates

Not all water requirements should be diversified. A supply to an irrigation system that is known to operate at 100% demand (2 L/sec) every day at 10am should be incorporated into the mains water pipe size calculator methodology .

For example:

Using the BS 8558:2015 pipe sizing method, a pipe that supplies 100 loading units will convert to 1.25 L/sec.

Because the irrigation system could operate at the same time as the peak usage of the building fixtures, the 2 L/sec should be combined directly with it (not combined and diversified).

This will result in a peak flow rate of 3.25 L/sec.

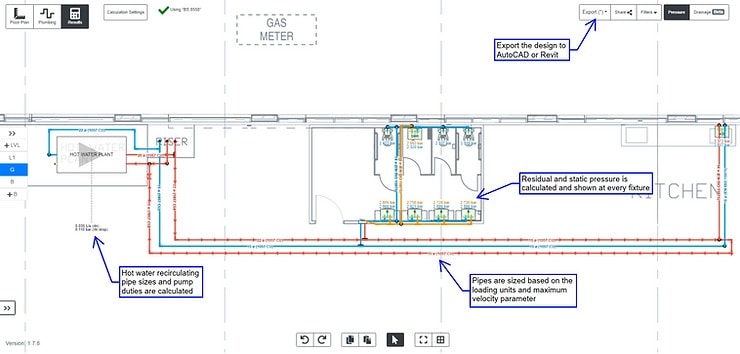

H2X – Mains Water Pipe Size Calculator

All of the different pipe sizing methods mentioned in this blog are included in H2X’s design and calculation tool.

In addition to providing you with accurate flow rates based on your design layout, H2X Pipe Velocity Calculator will also calculate the velocities, pressures, and heat loss for your Pipe Volume Calculator and Pressure Drop Calculator.

Once you have completed your design, H2X will export the layout into AutoCAD or Revit.

If you would like to try a free trial of H2X, you can start today by following this link.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP