Pipe Sizing for Heat Pump Systems (Includes a Worked Example)

It is commonly stated throughout the industry that heat pumps require 28mm pipes. This is a myth, is misleading, and should be avoided. Learn the correct way to size pipes for heat pump systems below.

Introduction to Pipe Sizing for Heat Pump Systems

It is commonly stated throughout the industry that heat pumps require 28mm pipes.

This is a myth, is misleading, and should be avoided.

The “28mm pipe” myth emerges from the understanding that heat pumps require larger flow rates than gas boilers.

So where a gas boiler system would typically need a 15mm or 22mm pipe, people are using rule of thumb to ‘guesstimate’ that 28mm should be appropriate for heat pumps.

The Problems with Incorrectly Sized Pipes in Heat Pump Systems

The correct pipe sizing in heat pump systems is critical for optimal operation and efficiency.

Both undersized and oversized pipes can lead to significant issues.

Problems with Undersized Pipes

- Reduced Efficiency: Due to their inability to maintain necessary flow rates for optimal heat exchange, undersized pipes can compromise the overall system’s efficiency.

- Increased Wear: Higher flow velocity in undersized pipes strains the system, leading to more frequent maintenance and potentially reducing its lifespan.

- Noise and Vibration: High-speed flows in smaller pipes can cause undesirable noise and vibrations.

- Elevated Energy Consumption: Systems with undersized pipes work harder to reach desired temperatures, leading to higher energy bills.

Problems with Oversized Pipes

- Higher Costs: Oversized pipes and fittings can unnecessarily inflate installation costs.

- Poor Heat Transfer: Lower flow velocities in larger pipes can result in suboptimal heat transfer and reduced system efficiency.

- Scaling and Corrosion Risk: Lower velocities can allow sediment to settle, leading to potential pipe scaling and corrosion.

- Energy Inefficiency: Larger diameters pipes lose their heat at a higher rate, contributing to higher energy consumption.

In summary, incorrect pipe sizing, whether undersized or oversized, can adversely affect your heat pump system’s performance, efficiency, and lifespan.

How to Size a Pipe Correctly

For a pipe to be 28mm, or any other size, it must be accurately sized.

To do this, you need to know:

- The load of the heat emitters connected to each pipe

- Refer to our blog Calculating Heat Loss for reference material relating to calculating the load of heat emitters

- The Delta T of the feed and return temperatures

- 5degC is generally recommended for heat pump systems

- It is advised to never go higher than 10degC

- The pipe material and its technical properties

- You can get this information from your preferred supplier’s technical data sheet

- The maximum design velocity

- MCS and CIBSE recommend a maximum of 1m/s

- The maximum allowable pressure drop per metre

- CIBSE recommend a maximum of 350 pa/m

Pipe Sizing For Heat Pump Systems Example:

Heat Emitters Connected to the Pipe

Heat Emitter 1 = 3kW

Heat Emitter 2 = 2kW

Total Load = 5kW

Delta T

The difference between the temperature on the feed and return pipes.

Heat pumps are recommended to operate around 40°C with a Delta T of around 5°C.

Feed temperature (40°C) – Return temperature (35°C) = Delta T of 5°C

Pipe Flow Rate

Convert the heat load to a flow rate.

Flow Rate (L/s) = Heat Load (kW) / (Delta T (°C) * Specific Heat Capacity of Water (kJ))

Heat Load = 5kW

Delta T = 5°C

Specific Heat Capacity of Water = 4.18kJ

Flow Rate = 5kW / (5°C x 4.18kJ)

Flow Rate = 0.24L/s

The flow rate should also consider the heat lost through the pipes.

This is very difficult to calculate and could be an blog in itself, so for simplicity, we are adding a factor of 10% to the heat emitter load.

Flow Rate = 0.24 L/s + 10%

Flow Rate = 0.264 L/s

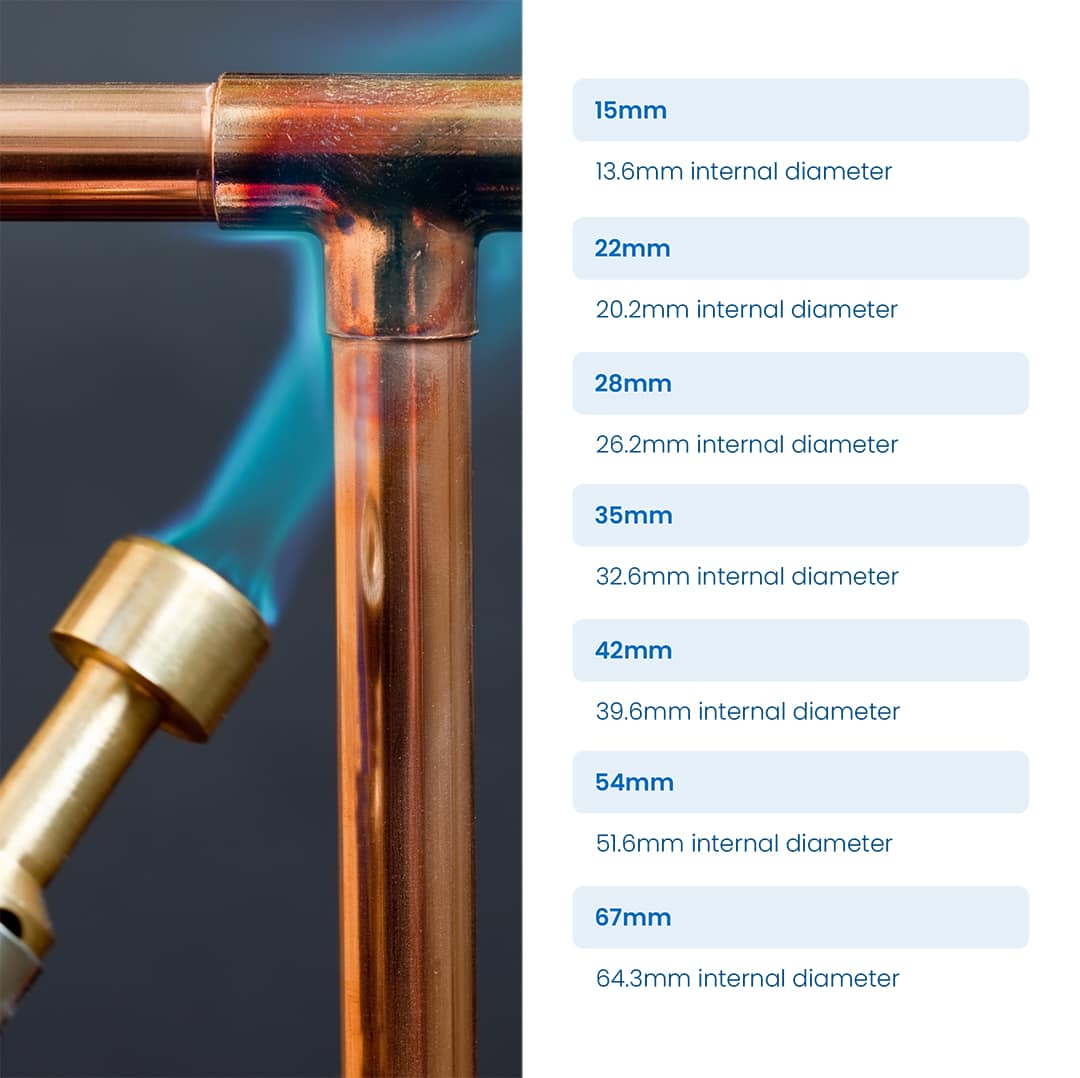

Pipe Properties

For the pipe material, the main piece of technical information you need to know is the internal diameter.

It is important you use the internal diameter rather than the nominal or external diameter otherwise the results will be incorrect.

For example, the internal diameter of copper pipes is:

15mm = 13.6mm internal diameter

22mm = 20.2mm internal diameter

28mm = 26.2mm internal diameter

35mm = 32.6mm internal diameter

42mm = 39.6mm internal diameter

54mm = 51.6mm internal diameter

67mm = 64.3mm internal diameter

Pipe Sizing Based on Velocity

A common method for pipe sizing is to ensure your flow rate is below a maximum velocity. The maximum velocity is generally limited to 1m/s.

Velocity (m/s) = (Flow Rate (L/s) / 1000) / ((3.14 * (Internal Pipe Diameter (mm)/2) ^2) / 100000

The results for 0.264L/s going through each copper pipe are shown below:

15mm = 13.6mm internal diameter = 1.82m/s

22mm = 20.2mm internal diameter = 0.82m/s

28mm = 26.2mm internal diameter = 0.49m/s

35mm = 32.6mm internal diameter = 0.32m/s

42mm = 39.6mm internal diameter = 0.21m/s

54mm = 51.6mm internal diameter = 0.13m/s

67mm = 64.3mm internal diameter = 0.08m/s

Based on a flow rate of 0.264L/s, the 22mm pipe (and larger pipes) have a velocity below 1m/s.

Try our free pipe velocity calculator.

Pipe Sizing Based on Pressure Drop

CIBSE recommends a maximum pressure drop of 350Pa/m.

So although the pipe velocity is below 1m/s, the velocity could still cause pressure drops that are too high for the recirculation pump to overcome.

Therefore it is important to know the pressure drop through the pipe by doing the pressure drop calculation.

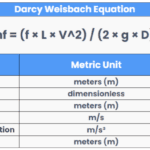

Pressure Drop (bar) = (Friction Factor x (Pipe Length (m) / Pipe Diameter (m)) x (Velocity (m/s)^2 / 19.62)) x 9084

Pressure Drop = 0.0274 x (1m / 0.0202m) x (0.82m/s / 19.62) x 9084

Pressure Drop = 426Pa/m

0.264L/s in a 22mm pipe has a pressure drop of 426Pa/m, which exceeds CIBSE’s 350Pa/m recommendation.

Whereas in a 28mm pipe, the pressure drop is 124Pa/metre.

Pressure Drop = 0.0292 x (1m / 0.0262m) x (0.49m/s / 19.62) x 9084

Pressure Drop = 124Pa/m

Therefore, based on the system design, velocity considerations, and pressure drop considerations, this pipe needs to be 28mm.

Try our free pressure drop calculator!

Case Study

Grant Store Ltd. had received advice from a manufacturer that their heat pump system needed a 28mm pipe.

When they chose a 28mm pipe in h2x, the velocity went up to 1.2m/s which is outside of the MCS guidelines.

Designing in h2x helped us to get the pipe sizes correct and avoid potential issues later down the track.

“After learning how to use the software, we are able to have a domestic project sized in no more than an hour or two.

We get a presentable PDF drawing set to share with our client and h2x automatically generates the Bill of Quantities at the same time, which is great for estimating and material orders.”.

Read more about how h2x helped Grant Store Ltd. on their project here!

» Click here to download our free eBook that breaks down everything engineers need to know about heat pump design!

The transformation of industries by the digital revolution is a story told many times over, and heating system design is no exception.

With the right software, like h2x Engineering’s Heating Design Software, you can drive efficiency and accuracy in your heating system projects.

Embracing the digital revolution in the form of heating design software, like that offered by h2x Engineering, is crucial for professionals who wish to stay competitive in the industry.

It offers a blend of convenience, precision, and efficiency that traditional methods cannot match.

Give your heating system designs the h2x advantage and experience the difference by booking a demo or by starting your free trial today!

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP