Exploring Hydronic Design Software with h2x Engineering

Dive into hydronic design software with h2x! Understand the formula, optimise performance, revolutionise HVAC design, and more.

Hydronic Design Software Introduction

Welcome to a journey into the world of hydronic design software, where innovation meets efficiency.

In this article, we look into the field of hydronic design and its intricate yet vital role in modern HVAC systems.

Specifically, we’ll explore the capabilities of h2x Engineering’s software in revolutionising hydronic design, offering engineers and designers a powerful tool to streamline their processes and optimise system performance.

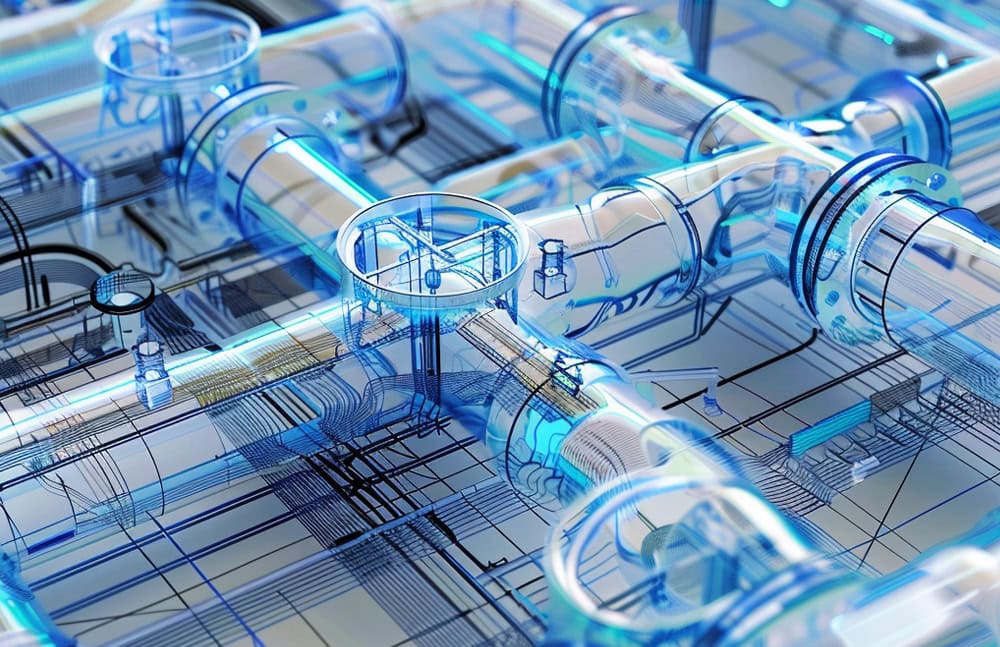

What Is Hydronic Design?

Hydronic design lies at the heart of efficient heating systems, utilising water as a medium to transfer heat throughout a building.

Unlike traditional forced air systems, hydronic systems offer superior comfort, energy efficiency, and zoning capabilities.

Whether it’s radiant floor heating, baseboard radiators, or fan coil units, hydronic design ensures optimal heat distribution tailored to the unique needs of each space.

Basics Of A Hydronic System

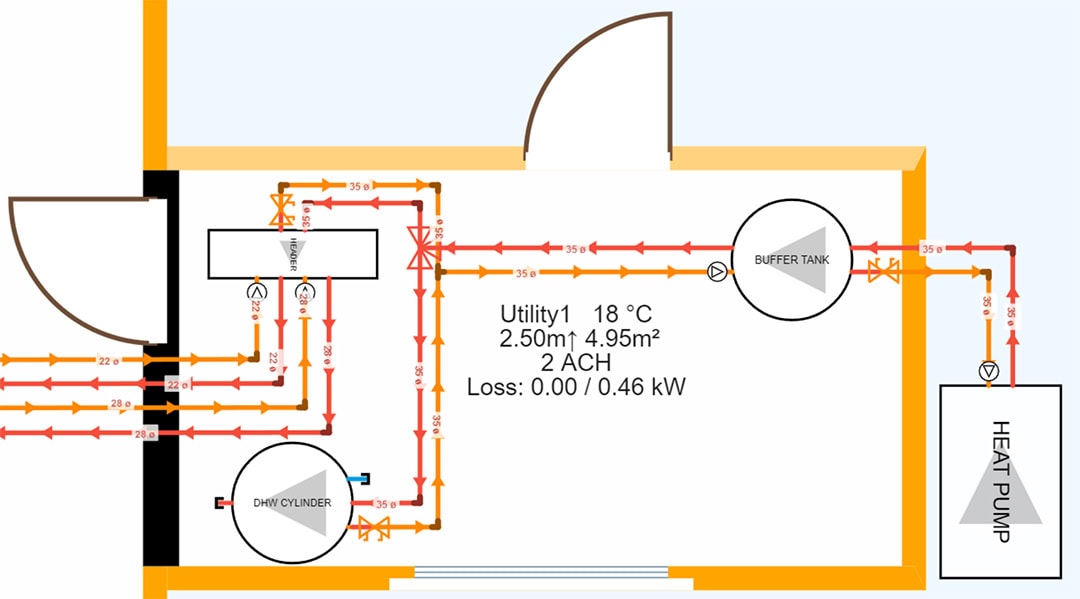

At its core, a hydronic heating system consists of a heat pump / boiler or water heater, pumps, piping, and terminal units such as radiators or underfloor tubing.

The heat pump / boiler heats water, which is then circulated through the piping network via pumps.

Terminal units release heat into the space, and the cooled water returns to the heat pump / boiler to be reheated-a continuous cycle of comfort and efficiency.

How To Design a Hydronic Heating System

Designing a hydronic heating system requires careful consideration of factors such as building layout, heat loss calculations, and equipment selection.

Engineers analyse building blueprints, insulation levels, and climate data to determine the optimal system configuration.

With a hydronic design progam like h2x’s solution, designers can efficiently model different scenarios, predict system performance, and fine-tune parameters to achieve optimal results.

Can You Install Hydronic Heating Yourself?

While some DIY enthusiasts may feel tempted to undertake hydronic heating installations, professionals typically perform this job best.

Designing and installing a hydronic system requires specialised knowledge of plumbing, electrical work, and HVAC principles.

Improper installation can lead to inefficiencies, comfort issues, and even safety hazards.

Consulting with a qualified hydronic engineer ensures a system that performs reliably and efficiently for years to come.

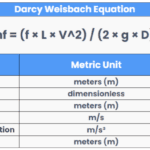

What Is the Hydronic Formula?

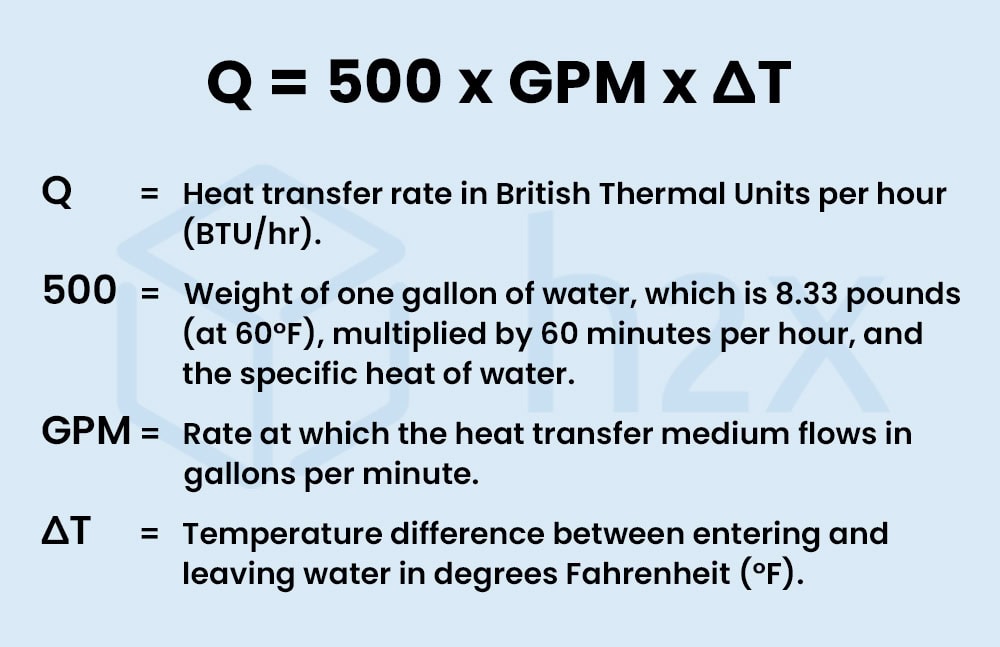

Known as the cornerstone of HVAC hydronics, the Universal Hydronics Formula is a vital equation in hydronic heating and cooling systems.

Utilising water as a heat transfer medium, it determines energy transfer for system optimisation.

Q = 500 x GPM x ΔT

where:

Q represents the heat transfer rate in British Thermal Units per hour (BTU/hr).

500 originates from the weight of one gallon of water, which is 8.33 pounds (at 60°F), multiplied by 60 minutes per hour, and the specific heat of water.

GPM represents the rate at which the heat transfer medium flows in gallons per minute.

ΔT is the temperature difference between entering and leaving water in degrees Fahrenheit (°F).

This formula ensures accurate sizing of system components, optimising heat transfer and overall performance.

By leveraging this formula, engineers and designers precisely size pumps, pipes, and heat exchangers, ensuring efficient heat transfer and meeting comfort requirements.

Putting Theory into Practice: A Real-World Example

Let’s consider a hypothetical scenario:

Imagine you’re tasked with designing a hydronic heating system for a commercial building.

Using the Universal Hydronics Formula above, you calculate the required heat transfer rate (Q) based on the building’s size, insulation, and heating needs.

After crunching the numbers, you determine that the system must handle a heat transfer rate of 100,000 BTU/hr.

With a flow rate (GPM) of 10 gallons per minute and a temperature difference (ΔT) of 20°F, you can now size the system components, such as pumps, pipes, and heat exchangers, accordingly to ensure optimal performance and efficiency.

Anyone involved in hydronic system design should aim to master the Universal Hydronics Formula.

By understanding the principles behind this formula and applying it effectively, engineers and designers can create systems that deliver optimal comfort, efficiency, and performance.

Hydronic Design Software With h2x

h2x Engineering’s hydronic design tool empowers engineers and designers with intuitive tools to streamline the design process and optimise system performance.

From heat load calculations to equipment selection and piping layout, h2x’s solution offers complete functionality backed by industry-leading expertise.

With its user-friendly interface and powerful simulation capabilities, h2x’s software sets a new standard for hydronic design efficiency and innovation.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

Conclusion

In conclusion, hydronic design software plays a pivotal role in shaping the future of HVAC systems, offering engineers the tools they need to create efficient, comfortable, and sustainable heating solutions.

With h2x’s software leading the way, the possibilities for hydronic design are boundless.

By embracing innovation and leveraging technology, we can pave the way towards a greener, more comfortable future.

FAQs

What sets h2x’s hydronic design software apart from others?

h2x’s software distinguishes itself through advanced simulation capabilities and user-friendly design tools, allowing engineers to optimise system performance effortlessly.

Furthermore, its intuitive interface facilitates seamless integration into existing design workflows.

Can hydronic heating be integrated with other HVAC systems?

Indeed, integrating hydronic heating systems with other HVAC components like air handling units and heat pumps provides comprehensive climate control solutions.

Is hydronic heating suitable for all types of buildings?

While hydronic heating is highly versatile, its suitability depends on factors such as building size, layout, and heating requirements.

We recommend consulting with a hydronic engineer for personalised advice.

Can hydronic heating systems be retrofitted into older buildings?

Yes, hydronic heating systems are adaptable and can often be retrofitted into older buildings with careful planning and implementation.

Experienced hydronic engineers can assess retrofit feasibility and develop tailored solutions for older structures.

Are there maintenance requirements for hydronic heating systems?

Like any HVAC system, hydronic heating systems require regular maintenance to ensure optimal performance and longevity.

This may include tasks such as inspecting and flushing the system, checking for leaks, and servicing pumps and heat pumps/boilers.

Implementing a maintenance schedule can help prevent issues and maximise system efficiency over time.

How does hydronic heating compare to traditional forced air systems in terms of energy efficiency?

Hydronic heating systems typically offer higher energy efficiency compared to traditional forced air systems.

By using water for heat transfer and zoning, hydronic systems offer precise comfort control and minimise energy use.

Additionally, radiant heating methods often result in reduced heat loss compared to ducted air distribution, further enhancing efficiency.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP