Exploring Continuous Flow Electric Water Heaters (CFEWH) With Rheem

Continuous flow, or instantaneous, electric water heaters (CFEWH) are not a new technology.

However, they have a heightened part to play in a low carbon energy future.

In this article, we look at the design features to consider when specifying this type of appliance.

Does Size Matter with Continuous Flow Electric Water Heaters?

Technically, a CFEWH uses the available electrical energy to heat resistance elements which in turn heat water passing through the heating chamber instantly.

The higher the kW rating produces more hot water.

The two related outcomes allied to this is temperature rise and flow rate, where one inversely affects the other.

Simply put, the higher the kW rating and the lower the temperature rise, the more flow rate available. For example, fixtures that the system can serve.

Choosing the highest kW rating available isn’t advisable, as one should consider other factors.

However, for most applications, a 3-phase power supply is necessary to meet common needs like showering and multi-point usage.

AS/NZS 3000 Wiring Rules

The ANZ Wiring Rules provide guidance in sizing wiring infrastructure for various types of applications employing this technology.

Apartments rightfully employ diversity of use to limit the amount of cabling required.

As extracted from AS/NZS 3000:

“For circuits supplying a single item of equipment, the circuit current is simply the nominal load current of the equipment. E.g. a 10,000W 230/400V three phase heater has a per-phase load current of 14.5A. The circuit conductors and the protective device are required to have a current-carrying capacity of not less than 16A (nearest standard rating).”

When connecting multiple pieces of equipment, we can assess the circuit current as the sum of the individual equipment load currents.

While safe and conservative, it overlooks normal operating conditions when equipment isn’t all running at full load constantly.

For example, submains to a distribution board associated with numerous socket-outlet circuits.

Under such conditions, we estimate the circuit current using diversity factors and often describe it as the after-diversity maximum demand.

Table C1, partially copied from AS/NZS 3000, provides guidance on after-diversity current for instantaneous electric water heaters in apartments:

Table C1 – Maximum Demand Single and Multiple Domestic Electrical Installations

Below are some practical examples.

We can observe that for apartments ranging from 21 to 25 living units, the calculated diversity load is actually lower than that for 20 apartments.

AS/NZS 3000 provides the following advice:

“It should be recognised that the determination of diversity factors given in this Appendix will not be accurate for every installation and different installations of the same type may have significantly different load profiles which the designer needs to consider.”

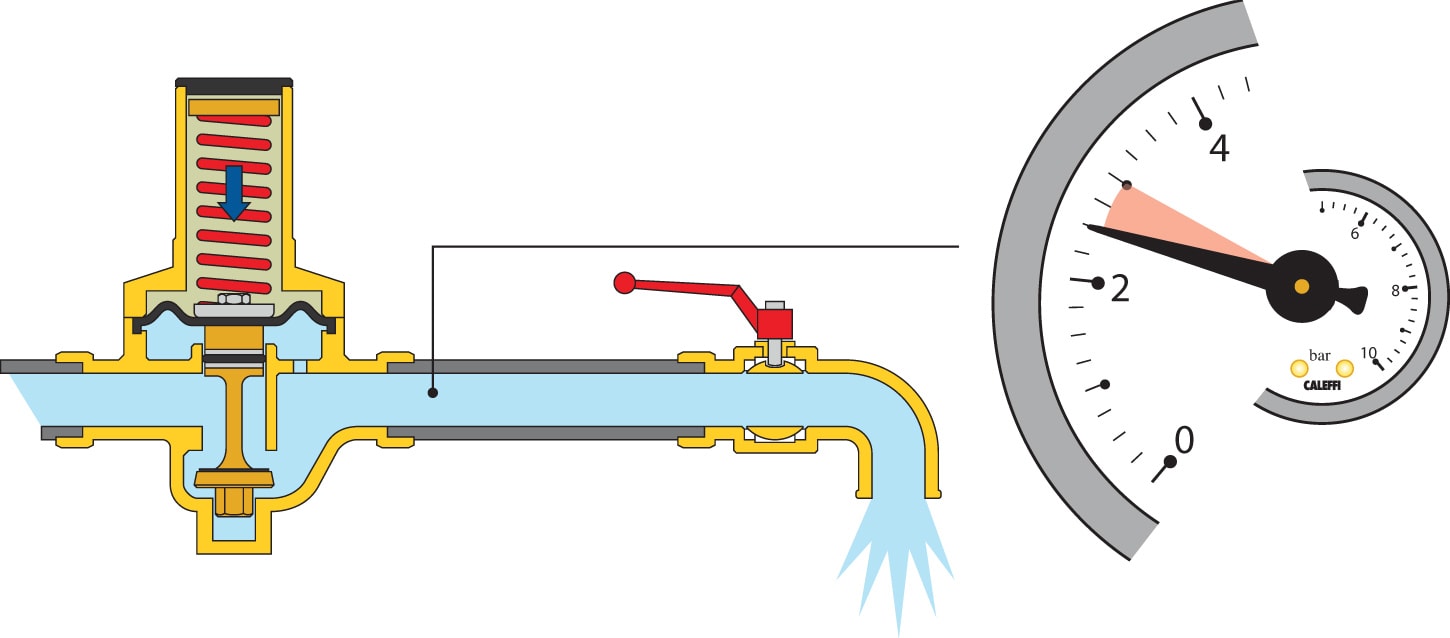

Dead Legs

In multi-residential developments, whether centralised or localised plant is used, the length of the run from the ring main or water heater becomes an issue, affecting the subsequent time to temperature.

Rheem Eclipse® heats water faster than other instantaneous electric models, by up to 10 seconds.

At a minimum flow rate of 3.7L/min this is 37 litres each time water is drawn.

The longer the dead leg, the more the effect heat loss has on delivered temperature.

WaterMark standards for 50°C limited models allow for trade adjustability, enabling the water heater to produce hotter water to achieve desired tap temperatures.

The combined features of faster time to temperature and trade temperature adjustability on Rheem Eclipse® reduce water and energy wastage.

Continuous Flow Electric Water Heaters – 50 °C vs 60 °C

For apartments, it is common to see multiple CFEWH installed, with larger 50 °C models serving bathrooms and smaller 60 °C models serving the kitchen/laundry.

In accordance with the plumbing code, 50 °C limited models must be marked as such and cannot deliver more than 50 °C at the taps (trade adjustability allows for up to 5 °C offset to be set to overcome any line heat losses).

Sizing

The key to model selection is simultaneous flow rate required within the application.

As discussed earlier, kW rating and temperature rise determine maximum flow capacity.

You can use the sizing guide below to determine appropriate product sizing based on flow rate requirements.

Design with Rheem’s Continuous Flow Electric Water Heaters in h2x

Are you looking for an efficient and convenient way to select and size continuous flow electric water heaters for your next project?

Rheem, a leading manufacturer of CFEWH, has teamed up with h2x’s design software, to provide a seamless specifying experience for engineers and contractors.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP