‘Erosion Corrosion’ in Water Systems

Erosion corrosion is a type of corrosion that occurs when water flows over a metal surface. The fluid flow can cause the metal to erode, and this erosion can lead to corrosion of the metal.

Plumbing system compliance relies on an all-important bedrock of technical calculations. However, the workflow followed to undertake these calculations are more outdated now than ever, often involving paper, rulers, and spreadsheets.

Luckily, modern solutions are available to help engineers design more efficiently and compliantly.

H2X, a plumbing design and calculation software, helps plumbing engineers to design compliant water, gas, wastewater, and heating systems, all according to the relevant standard.

This article will explore the most crucial plumbing requirements and see how H2X helps you meet them. Let’s get started.

Suggested reading: Read our article, H2X vs Spreadsheets, to learn more about the advantages and disadvantages of spreadsheet based calculations.

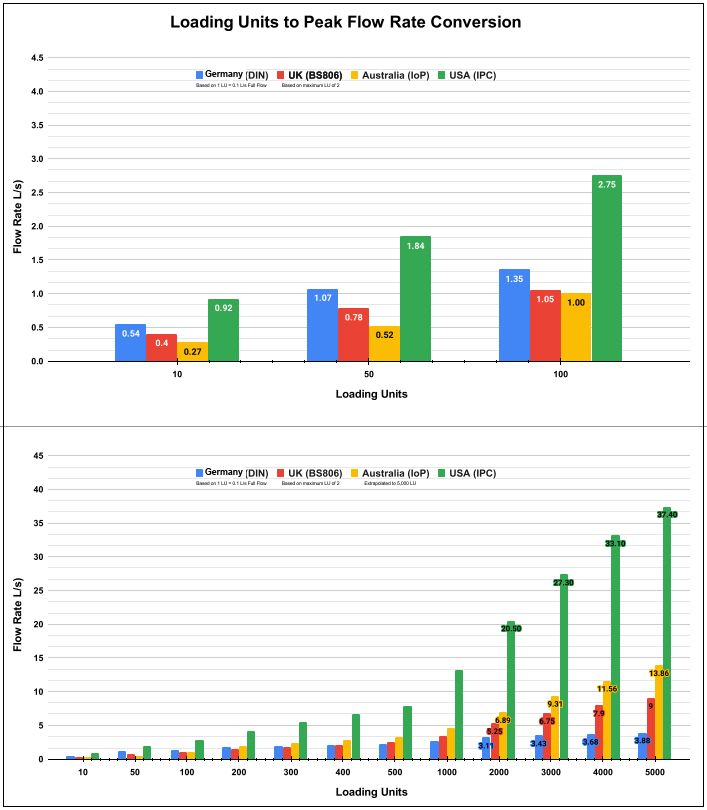

1. Peak flow rates

Peak flow rates are the basis for all plumbing system calculations.

Knowing the amount of water flowing through a pipe during a peak demand allows engineers to size every component of the water system accurately.

Yet calculating peak flow rates is no simple task.

Whilst the calculation is not rocket science, it involves a considerable amount of tedious and repetitive work to manually count which and how many fixtures are connected to each pipe, before converting that to a peak flow rate.

To add to the complexity of this process, the same building will receive different peak flow rate results in different states or countries:

Inaccuracies, whether made during the initial calculation phase or later in the project, as the architectural layout evolves, can cause significant problems to your design.

An incorrectly calculated peak flow rate leads to incorrectly sized pipes, pumps, and valves.

How can H2X help?

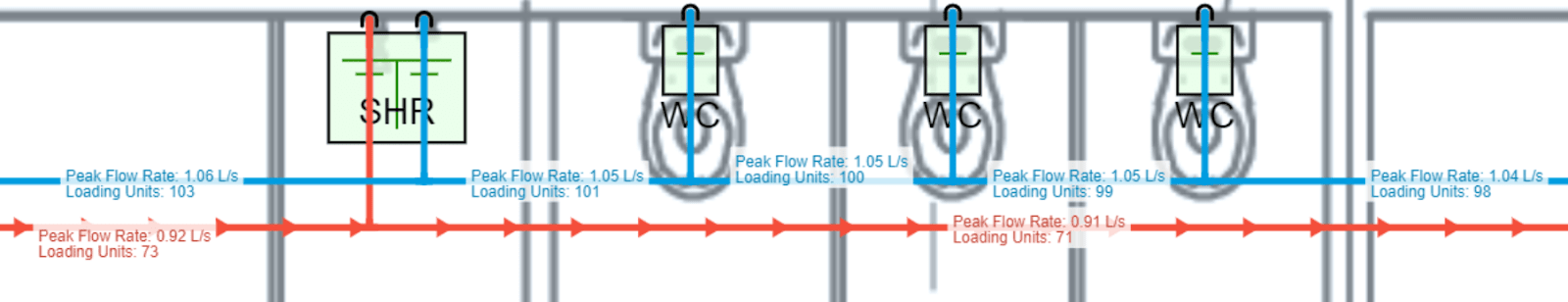

H2X helps engineers to quickly and accurately calculate peak flow rates:

- Choose the standard you want to calculate in accordance with.

- Connect fixtures or nodes to the pipe layout.

- Automatically receive the peak flow rate result for each pipe, valve, and pump.

2. Velocity

Velocity is the speed at which the water flows through the pipe. It is calculated using the peak flow rate and internal pipe diameter.

Designing the correct velocity is essential to a compliant plumbing system.

If you design to an incorrect velocity, you risk causing several problems to your system. Among these problems are:

- A non-compliant system that exceeds the standard’s maximum velocity.

- High friction losses, which lead to an inefficient system.

- Noise will occur at high velocities.

- Damage to the pipes will occur at high velocities.

- Low velocities cause poor hygiene in the water system.

Despite the importance of designing to the correct velocity, traditional methods make it a difficult calculation.

Each country also has its own recommended velocity, but generally they range between:

- Cold water velocity - 1.5-2.4 m/s or 5-8 ft/s

- Hot water flow velocity - 1.2-1.5 m/s or 4-5 ft/s

- Hot water return velocity - 0.7-1 m/s or 2-3 ft/s

Pro tip: Try using our free pipe velocity calculator to calculate the velocity of your plumbing system.

How can H2X help?

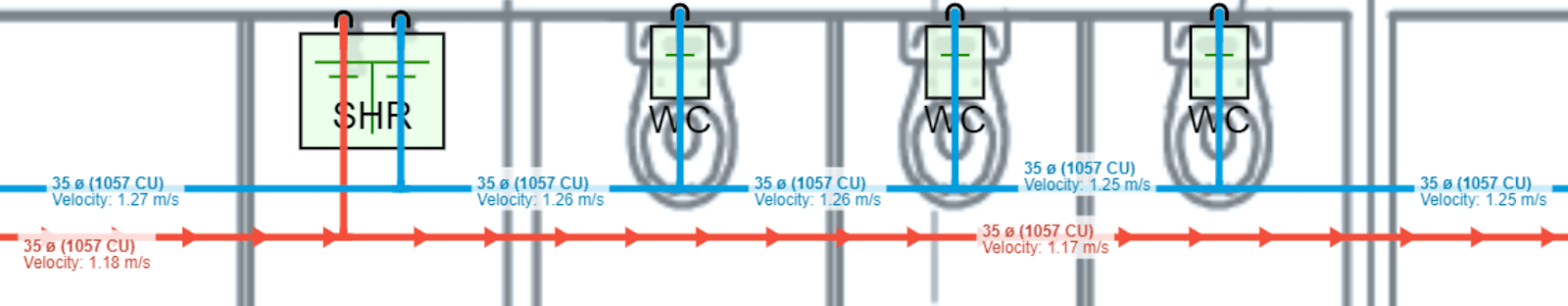

H2X helps engineers to quickly and accurately calculate the velocity through each pipe:

- Choose the maximum velocity parameter for your design.

- Connect fixtures or nodes to the pipe layout.

- Automatically receive all pipe size results based on the maximum velocity setting.

H2X offers free trials to allow users to experience the benefits of plumbing system design software firsthand: book a demo today.

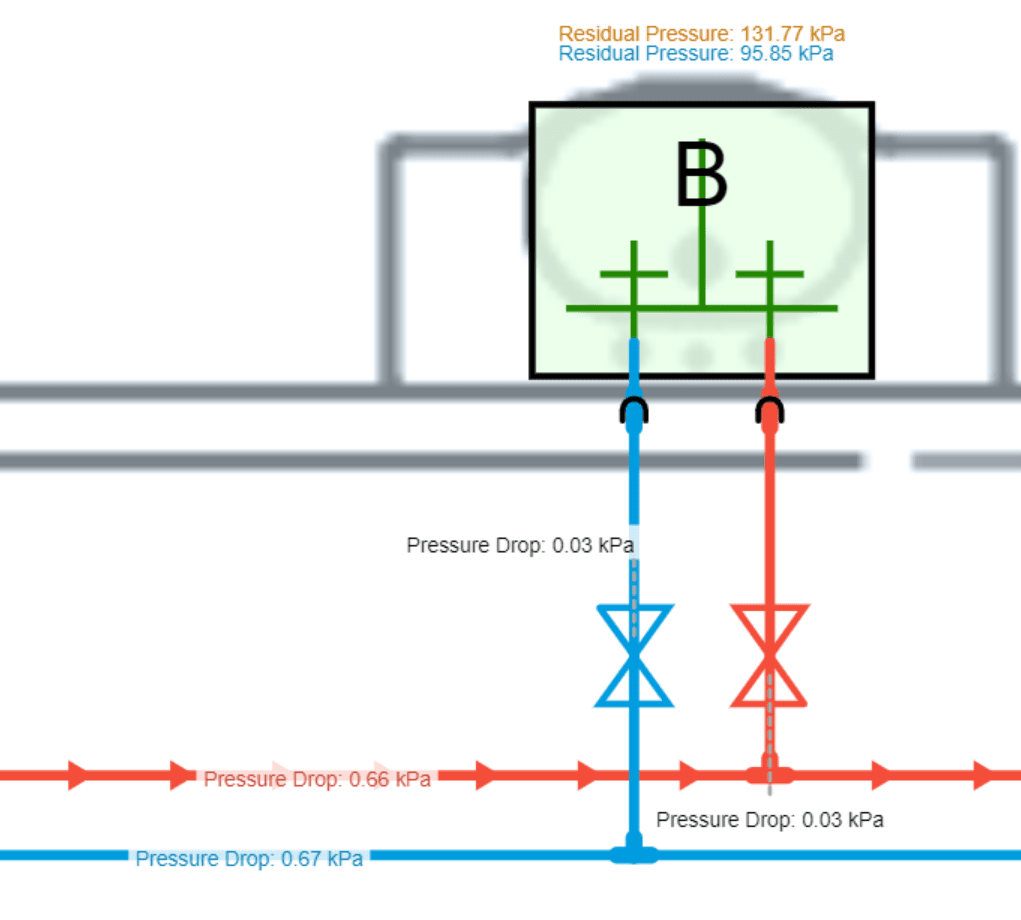

3. Residual pressure

Residual pressure is the minimum pressure you can expect in a water system, and is caused by a water system operating in ‘peak’ conditions.

In peak conditions, flow rates increase, which means the system pressure decreases.

Suggested reading: If you want to learn more about why residual pressure matters, check out our article on the subject — ‘Why is residual pressure important’.

Although residual pressure regulations will differ depending on your local standards and the products used, the typical minimum inlet pressure for components is 100 kPa / 1 bar / 15 psi.

Maintaining at least the minimum level of residual pressure is essential because it prevents:

- Warranties becoming void: components suffering extremely low levels of residual pressure will lose their warranty, causing extra costs for you and your clients.

- Non-compliance issues: not complying with the relevant standards can damage your engineering reputation, often resulting in extra costs.

- Poor system functionality: system functionality defines whether the endless calculating and recalculating behind a project has been worth it. Residual pressure directly impacts the functionality of your system.

However, despite the residual pressure calculation being crucial to an effective plumbing system design, traditional methods make it challenging to undertake.

Pro tip: Try using our free pressure drop calculator to calculate the friction loss through pipes.

How can H2X help?

H2X, an industry-leading plumbing system design software, helps engineers quickly and accurately calculate the pressure through their system:

- Input the residual pressure at your water connection.

- Choose your design's maximum pressure drop per metre/foot parameter.

- Connect fixtures or nodes to the pipe layout.

- Automatically receive pressure results throughout the whole system.

As part of our mission of overcoming plumbing design defects, we offer ‘Design Warnings’ that show users where their design is non-compliant and where changes, such as adding a pump, need to be made.

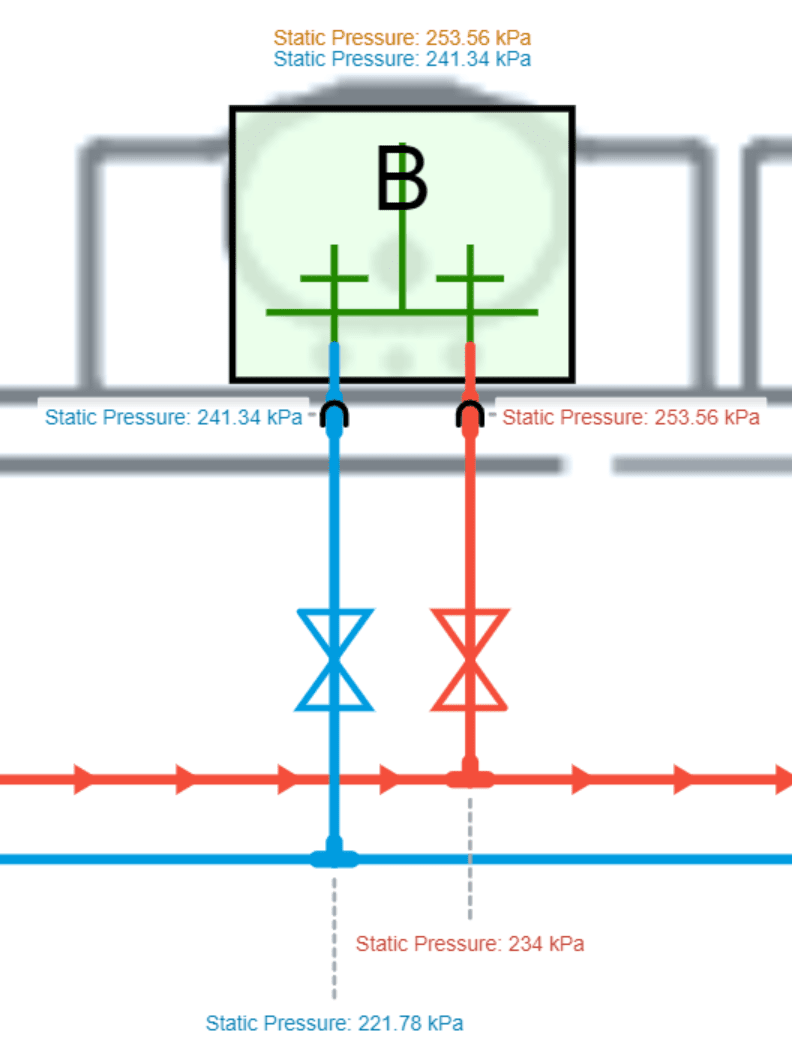

4. Static pressure

Closely related to residual pressure, static pressure is the maximum pressure you can expect to see within your system.

As the name suggests, static pressure is caused by water being in a static state. As flow rates decrease, the system pressure increases.

The typical inlet static pressure for components is:

- TMV – 500kPa / 5bar / 75psi

- RPZ – 1600kPa / 16bar / 230psi

- Fixtures – 500kPa / 5bar / 75psi

- 50mm Copper Pipe – 1710kPa / 17.1bar / 250psi

- 50mm Steel Pipe – 6800kPa / 68bar / 1000 psi

So, why is static pressure important?

Our answers are similar to those we gave on residual pressure - excessive static pressure will result in warranties becoming void and non-compliant systems. This will damage your engineering reputation whilst causing extra costs for you and your clients.

Keeping the static pressure within an accepted range typically requires careful calculation and regular redesigns.

How can H2X help?

Employing plumbing system design software can help ensure all of your pressure calculations are accurate. H2X allows engineers to quickly and accurately calculate the pressure through their system:

- Input the residual pressure at your water connection.

- Connect fixtures or nodes to the pipe layout.

- Automatically receive pressure results throughout the whole system.

Plumbing design can make all the difference to the compliance of your system. Our ‘Design Warnings’ show users where their design is non-compliant and changes, such as adding Pressure Reduction Valves, need to be made.

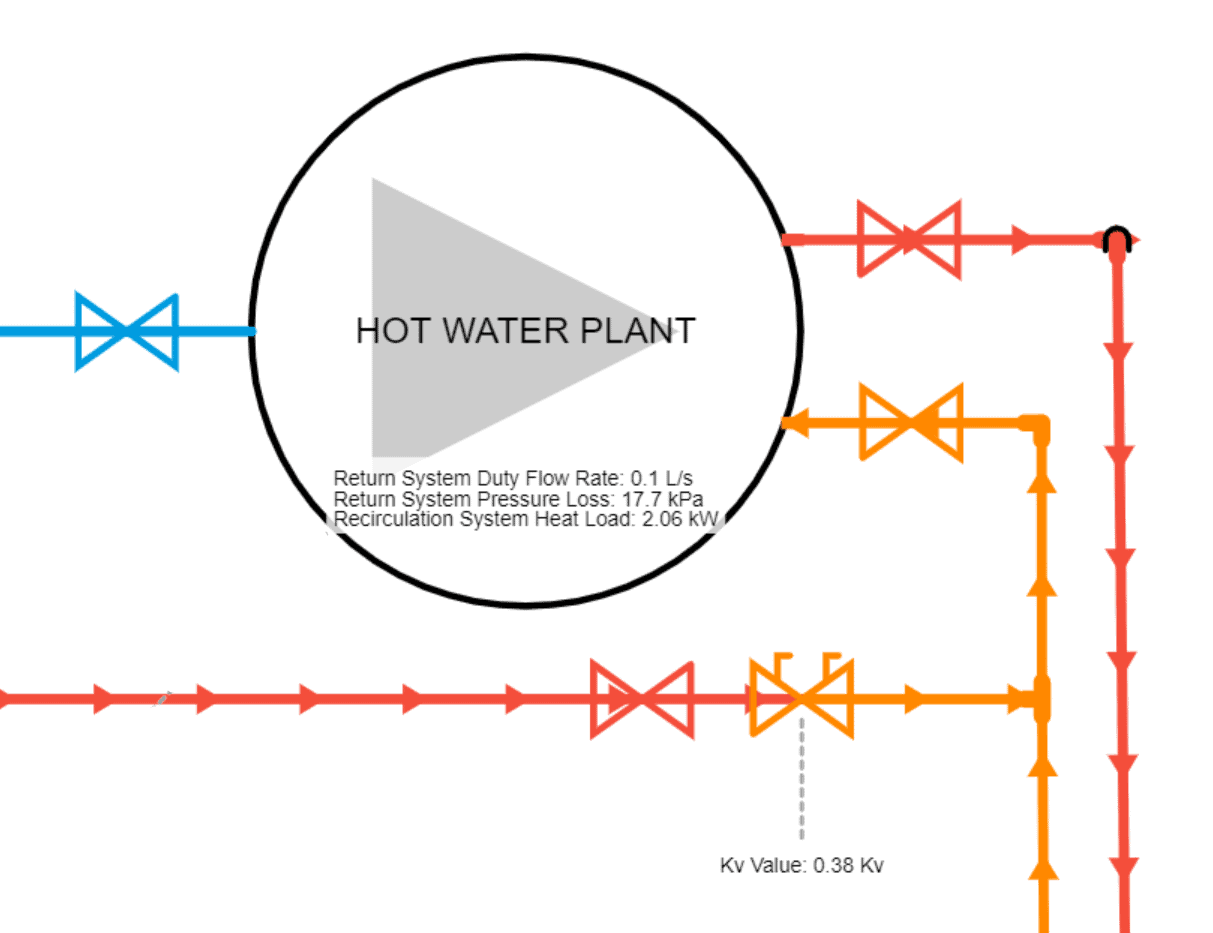

5. Hot water recirculation

A hot water recirculation system can be simply described as a system that offers a steady supply of hot water to fixtures whilst recirculating unused hot water back into the water heater.

The market share of hot water recirculation pumps is expected to increase by $1.69 billion between 2020 and 2025, paving the way for more recirculation systems and — for engineers — more challenging designs than ever before.

Their rise in popularity is because recirculation systems allow users to reduce their water usage, and minimise those annoying day-to-day waiting times at the shower.

Everyone agrees that accurately designing a hot water recirculation system is complicated. When designing, you must know the following information:

- The system’s pipe sizes.

- The length of each pipe size.

- The delta T of the hot water recirculation system.

- The ambient temperature.

- The air speed.

- The technical properties and thickness of the insulation.

Once this information is available, you must undertake highly complex physics calculations to determine the heat loss flow rate.

Once you have the heat loss flow rate, the following steps are:

- Distribute the flow rate through each circuit on the floor plan.

- Size the return pipes (which will add extra heat loss flow rate to your calculations).

- Calculate the exact pressure through each circuit.

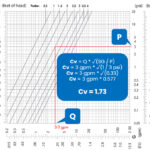

- Balance the system using balancing valves.

- Choose a recirculation pump to suit the system's flow rate and pressure requirements.

Due to the process described above, it is no surprise that traditional methods are insufficient for accurate hot water recirculation system calculations.

Suggested reading: For an in-depth insight into the designing process of a hot water recirculation system, check out our article, How to design a hot water recirculation system in a high rise building.

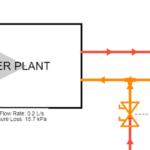

How can H2X help?

H2X automates all of your hot water recirculation system calculations, taking into account the design layout and unique system parameters.

- Set your pipe sizing parameters.

- Choose your insulation material.

- Connect fixtures or nodes to the pipe layout.

- Automatically receive results for the whole recirculation system.

This improves calculation accuracy, standardises outcomes across each team member’s page, and allows for accessible redesigns.

Calculations software that empowers engineers

H2X is a plumbing system design software built to ensure compliance, efficiency, accuracy and collaboration.

Its straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo with us today to discover how H2X can help you improve your design and calculation workflow.

"Great product. H2X saves time on calculations and markups."

- Josh Borthwick

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP