Why is Residual Pressure Important?

Calculating Residual Static Pressure is the minimum pressure that you can expect in the water system. It is caused by the water system operating under 'peak' conditions.

What is residual pressure?

Calculating Residual Static Pressure is the minimum pressure that you can expect in the water system.

What causes residual pressure?

It is caused by the water system operating under ‘peak’ conditions.

When is a water system under ‘peak’ conditions?

A water system operates anywhere between the following flow rates:

- Peak – such as 8am when everyone is showering before work; and

- Static – such as in the middle of the night when no one is using water.

Therefore, the system is’ peak’ when the water system is operating at the maximum flow rate.

How does the flow rate affect the pressure?

When the flow rate increases, the pressure decreases.

Therefore, when the flow rate increases to the peak condition, the residual pressure decreases to its lowest possible point.

Why does residual pressure matter?

Every component in a water system has a minimum inlet pressure.

Moreover, if the pressure in the system falls below the minimum inlet pressure, the following occurs:

- The warranty of the component(s) will be void;

- The component (pipe/valve/taps) will not function properly; and

- The system design will be non-compliant.

What pressure should I design?

The typical minimum inlet pressure for components is:

- TMV – 100kPa

- RPZ – 200kPa

- Fixtures – 100kPa

- 50mm Copper Pipe – N/A

- 50mm Steel Pipe – N/A

Prior to undertaking your design, to ensure your design meets the correct minimum pressure, you should always check:

- The technical data sheet of the products that you are using

- The requirements in your local standards

How to calculate residual pressure?

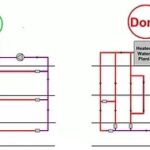

As visualised in the image above, the pressure throughout the building is then affected by water travelling through:

- Pipes;

- Valves;

- Fittings; and

- Changes in Height.

Residual Pressure Example

In this example, we will calculate the pressure in a simple scenario of supplying one hose tap in a car park.

Project information

Utility information:

Water Main Height: 14m

Residual Pressure: 270 kPa

Building information:

Floor Height: 15m

Fixture information:

Height Above Floor: 0.5m

Minimum Inlet Pressure: 200 kPa

System information:

Flow Rate: 0.5 L/s

Pipe Diameter: 25mm

Residual Pressure Calculation

The peak flow rate causes pressure loss through:

- Pipes – calculated using the Darcy Weisbach equation (try our calculator)

- Valves – calculated using their kV/zeta values or manufacturer’s data

- Fittings – calculated using their kV/zeta values

There is also pressure loss caused by the vertical height difference between the water main and the hose tap – this is not affected by the flow rate.

Utility Residual Pressure = 270 kPa

Pipe Pressure Loss = – 17.43 kPa (20.5m x 0.85 kPa/m)

Valve Pressure Loss = – 76.52 kPa (0.05 + 0.3 + 1.5 + 74.17 + 0.05 kPa)

Fitting Pressure Loss = – 3.12 kPa (6 x 0.52 kPa)

Vertical Height Change = – 14.72 kPa (1.5m x 9.81 kPa)

Fixture Residual Pressure = 158 kPa

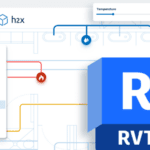

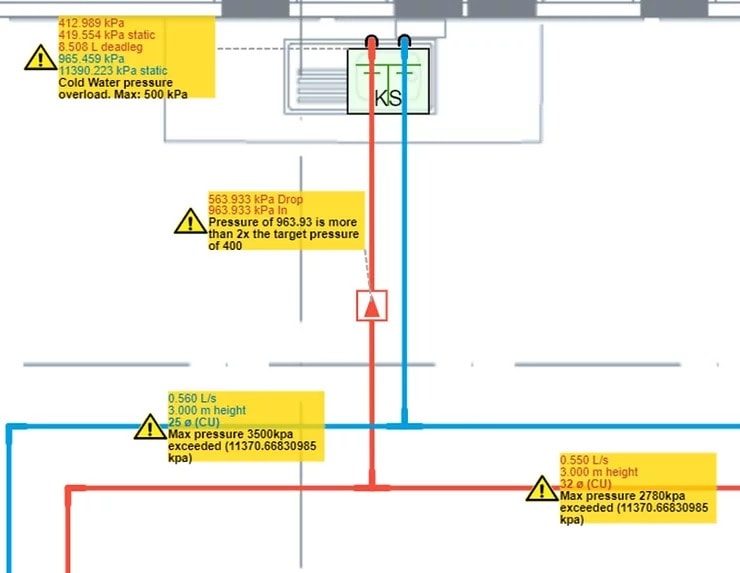

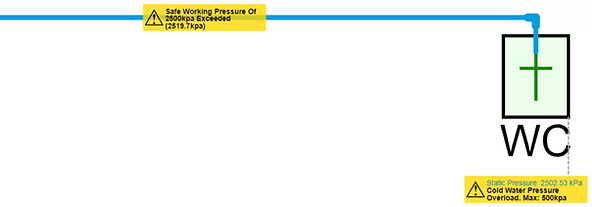

This can be visualised in the below image taken from H2X’s design software:

What if there is not enough pressure?

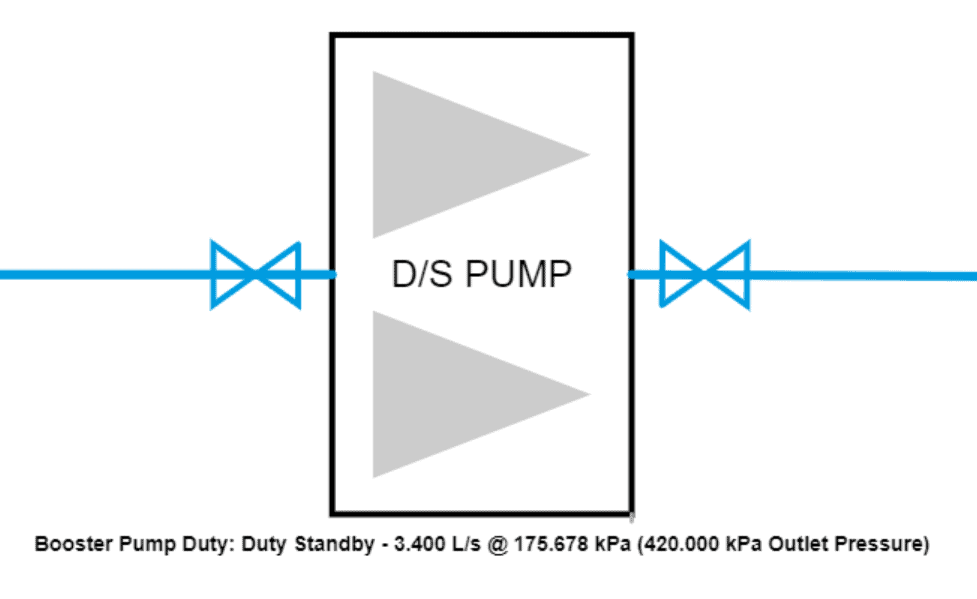

If the residual pressure is below the minimum inlet pressure of a component in the system, you will most likely need to add a booster pump.

For example, the residual pressure at the hose tap is 158 kPa (42 kPa below the minimum inlet pressure).

If you add a booster pump to your design with an additional pressure of 100 kPa, the pressure at the hose tap (258 kPa) will then fall within the 200 – 500 kPa pressure range.

H2X automates the pressure calculations based on the inputs from the water connection, the water system, and the heights assigned to your fixtures/nodes.

Also, warnings are provided where the pressure exceeds the component(s) minimum inlet pressure.

And, booster pumps are automatically sized when you add them to your design.

H2X was built by engineers to help engineers work faster, better and more effectively.

If you would like to try H2X today, sign up for a 14-day free trial now.

5 Reasons Industry Experts Design with H2X

- Exceptional Support

- Proven & Reliable

- Ease Of Use

- Built By The Industry

- Worldwide User Base

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!