How to Design Hot Water Recirculation Systems in High-Rise Buildings

Lets start with understanding the basics of hot water recirculation systems. Have you ever waited a long time for hot water to come out of the tap?

Step 1 - What is a hot water recirculation system?

Lets start with understanding the basics of hot water recirculation systems.

Have you ever waited a long time for hot water to come out of the tap?

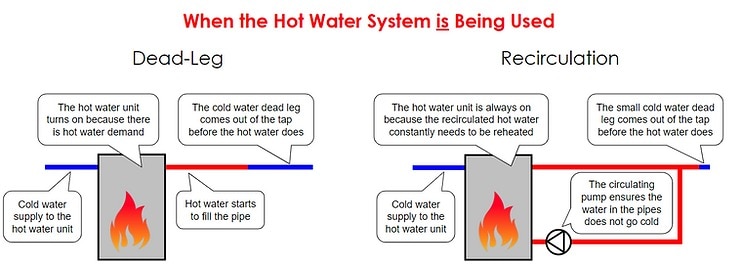

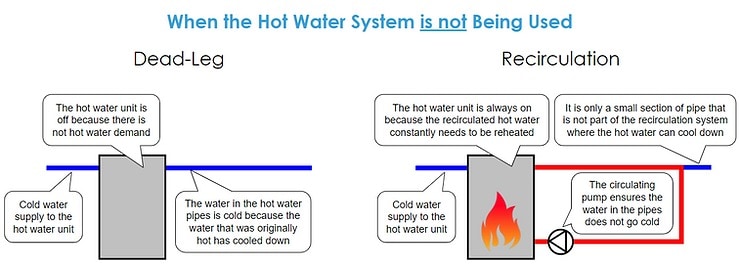

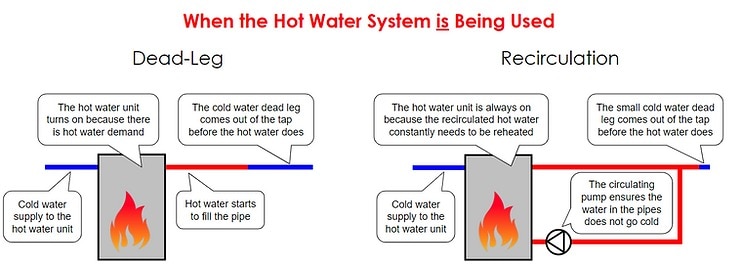

It is likely that the long wait is because the building has a dead-leg hot water system.

A hot water recirculation system prevents this long wait by constantly circulating hot water and to minimise the length of the dead leg.

Below is a simple visual comparison of a dead-leg and recirculation hot water system:

Step 2 - Do you need a hot water recirculation system?

Waiting for hot water is tolerable in some circumstances, but a dead-leg system in a large building is not fit for purpose.

In large buildings, a hot water recirculation system has a lot of benefits, mainly:

- They prevent you from waiting a long time for the hot water to come out of taps

- They prevent you from wasting cold water whilst waiting for the hot water

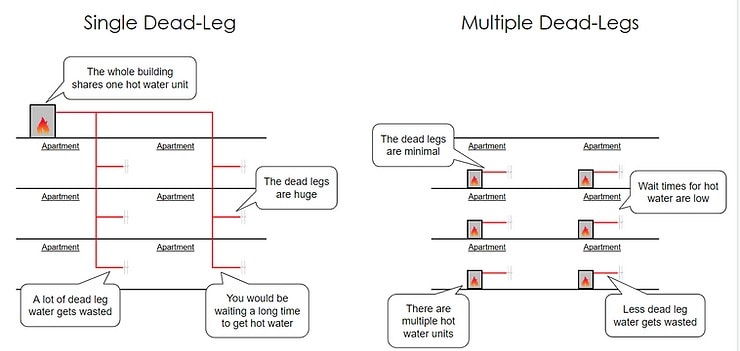

Providing multiple dead leg systems is another common way to provide hot water in a high-rise building. They are especially common in apartment buildings, where every apartment has their own hot water plant. A simple diagram is below:

Multiple dead leg systems achieve the same benefits as the recirculation system and is a much simpler design.

However, the main drawback is the cost associated with the additional hot water plant.

If you think a hot water recirculation system is still the best option for your project - keep reading!

Step 3 - Balancing a hot water recirculation system

The concept of 'balancing' is the foundation for understanding how to design hot water recirculation systems.

We recommend not moving past this part until 'balancing' makes sense. When it makes sense, the rest of the blog will be easier to follow.

The fundamental of 'balancing' a hot water recirculation system is to understand that:

Water takes the path of least resistance.

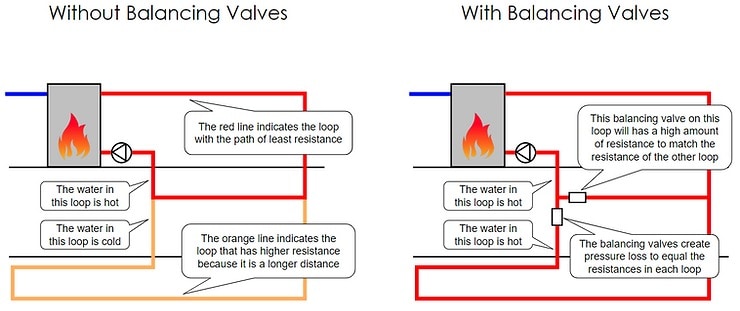

When a hot water recirculation system is split up into different loops (generally one loop per level), each loop usually consists of different pipe sizes and lengths.

A large diameter pipe has less resistance than a small diameter pipe.

A short length of pipe has less resistance than a long length of pipe

Therefore each loop has a different amount of resistance for the water.

So what will the hot water that is being circulated by the pump do? It will take the path of least resistance i.e. the loop with the largest pipes and/or shortest lengths.

This means that the loop with the path of least resistance will circulate correctly (at the right temperature), but the water in the other loops, which have more resistance, may barely move (and will be at a wrong/cold temperature).

Balancing valves fix this by creating resistance, making the water work equally as hard to go through each loop.

The less resistance a loop has, the higher resistance it's balancing valve needs.

Once the resistance is equal in each loop, the system is 'balanced', and the hot water will circulate equally (at the right temperature).

Step 4 - Pressure in high-rise buildings

Designing a hot water recirculation system in high-rise building presents a new challenge.

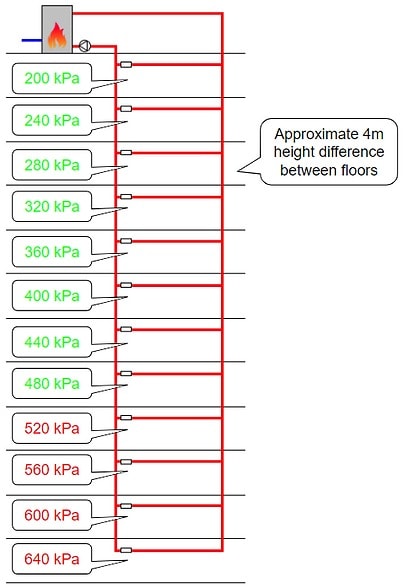

To design a compliant system, you need to achieve a minimum pressure at every fixture.

That minimum pressure is given to us by standards and guidelines and it is generally around 200 kPa / 2 bar / 25 psi.

To meet the minimum pressure requirement in a high-rise building, you will require a pump because water loses approximately 10 kPa / 0.1 bar / 1.5 psi per metre it rises.

Although this pump helps us to meet the minimum pressure requirements, we cause a problem elsewhere because the maximum pressures we need to meet too and that is generally around 500 kPa / 5 bar / 80 psi.

By achieving the minimum pressure at the top of the building, you almost certainly exceed the maximum pressure at the bottom of the building.

An example of the pressure in a high-rise building is shown below:

Step 5 - Pressure reduction valves

The easiest way to control the pressure in the hot water system is to add pressure reduction valves (PRVs).

It is very important to know that where you locate the PRVs will make or break the hot water recirculation system.

One solution is to put the PRVs on the dead legs that branch off the hot water recirculation system's flow and return pipework.

This works but there are three drawbacks that prevent it from being a common solution:

- High Pressure - PRVs have a maximum inlet pressure of 2,000 kPa / 20 bar / 290 psi. Some building's exceed this pressure which prevents them from being used

- Capital Cost - there could be thousands of branches in a high-rise building. Installing a PRV on each branch can increase the cost of the system significantly

- Maintenance - every component in the system has a limited design life. When the design life of the PRVs expire, they need to be replaced which is another significant cost

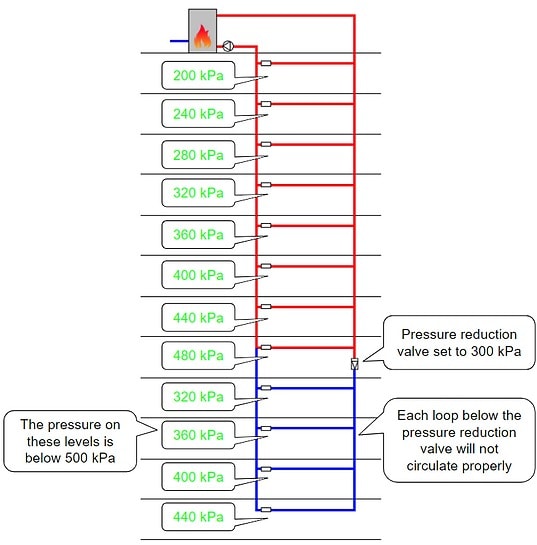

It is commonly thought that a better solution would be to put one PRV per level on the hot water recirculation system's flow and return pipework. You should not do this.

If you put PRVs on the hot water recirculation pipes it will unbalance the system because of the significant amount of resistance it creates to some loops. See the example below:

A better solution in high-rise buildings is to create pressure zones within the hot water recirculation system.

Step 6 - Designing pressure zones

Pressure zone - a zone within the building where the pressure is in the desired range.

e.g. 200-500 kPa / 2-5 bar / 25-80 psi.

To achieve this desire pressure range you will need to add a PRV to the riser and then create a new zone.

When you create the pressure zone, you are effectively creating a new hot water recirculation system. This needs a dedicated hot water recirculation pump and heat exchanger.

Most importantly, designing like this will lead to a balanced system.

Summary

- Do you need a central hot water recirculation system? If so,

- Does it make sense to add a PRV to each branch? If not,

- Create pressure zones.

Did you know H2X's design software makes the hot water calculation process much simpler?

Simply draw the layout of the hot water system, set your design parameters, and all of the hot water recirculation calculations will be undertaken.

The detailed and accurate results include:

- Heat loss flow rates;

- Return pipe sizes;

- Recirculation pump duty (flow rate and pressure);

- Balancing valve settings; and

- Much more.

You can see an overview in this video:

If you would like to learn more about H2X, we would love to hear from you. You can request more information here.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP