Booster Pumps

Booster pumps increase the water pressure within a system. As a rule of thumb, you will need a booster pump if either of the following applies...

What are booster pumps?

Booster pumps increase the water pressure within a system.

Do you need a booster pump?

As a rule of thumb, you will need a booster pump if either of the following applies:

- It is a medium or high-rise building

- Water pressure decreases as it rises in height, increasing the likelihood of a booster pump

- There is a water storage tank

- The pressure on the outlet of a storage tank is low, generally around 20kPa / 3psi / 0.2bar

To know for sure whether you need a booster pump, you will need to undertake calculations.

Booster pump calculation:

To check if you need a booster pump without undertaking detailed calculations, a simple check is:

Available Pressure Loss = Water Main Residual Pressure – Vertical Pressure Loss – Fixture Minimum Pressure

The ‘available pressure loss’ result is the pressure you can afford to lose through your pipes, valves, and fittings.

If the ‘available pressure loss’ is negative or very low, you will need to add a pump.

Booster pump example:

Using some assumed numbers, an example of the simple calculation is below:

Water Main Residual Pressure = 200kPa / 30psi / 2bar

Vertical Pressure Loss = 50kPa / 7.5psi / 0.5bar

Fixture Minimum Pressure = 100kPa / 15psi /1bar

Available Pressure Loss = 50 kPa / 7.5psi / 0.5bar

The available pressure loss (50 kPa / 7.5psi / 0.5bar) is relatively low, which indicates you will likely need a booster pump.

To do more detailed calculations on the pressure loss through the system’s pipes, valves and fittings, learn the process in our pressure loss blog post.

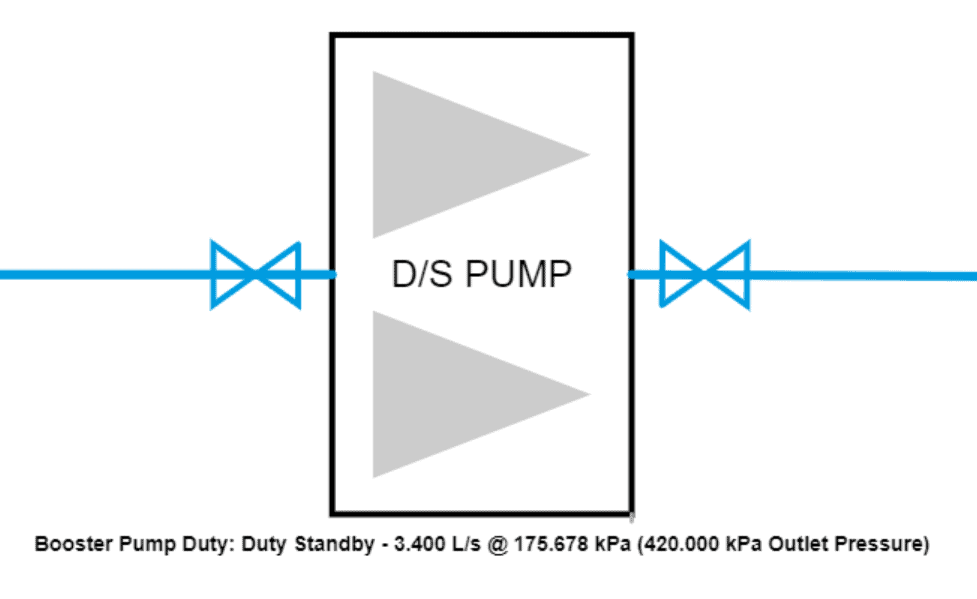

The booster pump duty

There are two parts to the pump duty:

- Flow rate

- The pump must be capable of supplying the building’s peak flow rate.

- Pressure

- The pump must be capable of supplying pressure to the most disadvantaged fixture

The pump duty is important as it informs selecting the correct booster pump for your application.

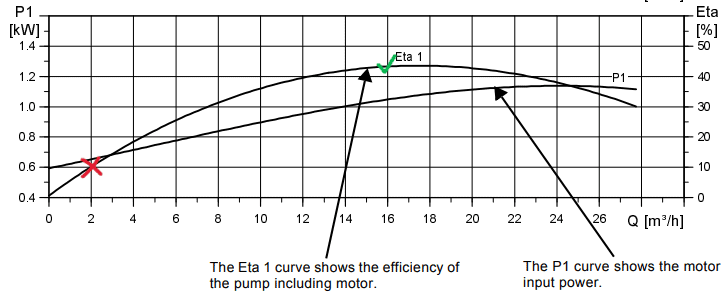

Booster pump curves

Once you have calculated the booster pump duty, you need to select the correct booster pump.

To check whether a pump is suitable for your design, you need to check its pump curve.

The pump curve indicates what flow and calculating Residual Static Pressure. The booster pump are capable of supplying.

Booster pump curve example

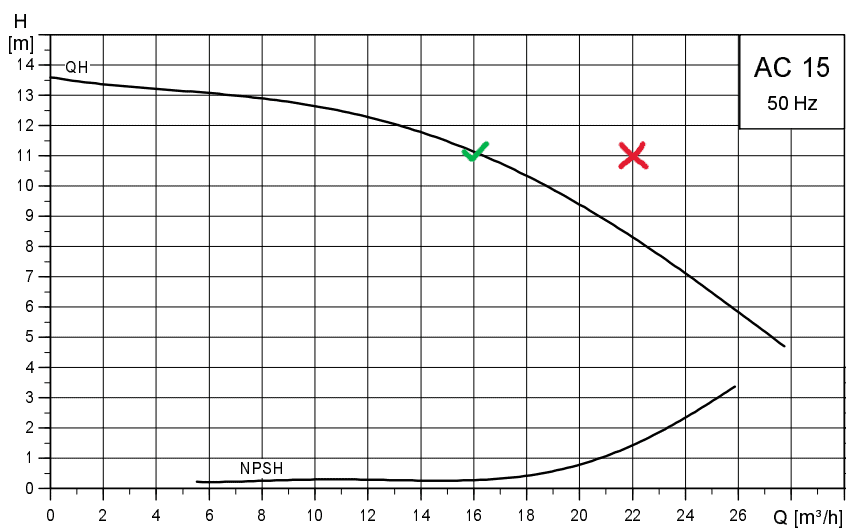

If the pump duty was 11mH @ 22m³/h, it would be above the ‘QH’ line on the below pump curve. Therefore, this pump would not be suitable and you would need to look at a larger model.

However, if the pump duty was 11mH @ 16m³/h, it would be close to the ‘QH line’ on the pump curve. Therefore, this pump would be a suitable selection.

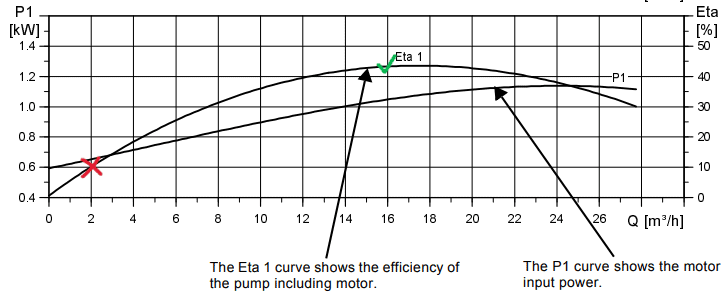

Not only should the pump duty fit on the pump curve, but you also need to ensure it is in an efficient section of the pump curve.

For example, if the pump duty is around the edges of the pump curve, such as 2m³/h, it is not an efficient selection.

Although the pump can supply the duty, it is not going to be energy efficient. Whereas if the duty is 16m³/h, it is closer to peak efficiency.

What booster pump arrangements are available?

There are various arrangements of booster pumps available.

Before looking at the various arrangements, you should understand some common pump terminology:

- Duty Pump

- The duty pump is capable of supplying the system with the required flow and pressure under most scenarios

- Assist Pump

- The assist pump supplements the duty pump, sharing the load when the duty pump can’t meet the required flow and pressure

- Standby Pump

- The standby pump is a backup to the duty pump, with the same pressure and flow capabilities.

- The duty and standby pumps switch over regularly to ensure there is equal wear on them

There are various configurations of these pump types, the most common are:

- Duty

- This is suitable for projects where minimal cost is important and downtime due to maintenance is not an issue

- For example, this might be suitable for a house but it would terrible in a hospital

- Duty/Standby

- This is suitable for most projects as it is relatively cost-effective and provides redundancy during maintenance

- When the project has a large peak demand, it becomes an increasingly inefficient solution because each pump has to provide the full amount of flow and pressure

- Duty/Assist

- Similar benefits to Duty/Standby but each pump is only capable of a lower flow and pressure

- This is a more cost-effective and efficient solution than Duty/Standby but it provides less redundancy

- Duty/Assist/Standby

- This is suitable for projects with a large flow and pressure requirement where redundancy is important

- Duty/Assist/Assist

- This is suitable for projects with a large flow and pressure requirement where redundancy is not the priority

- Duty/Assist/Assist/Standby

- This is suitable for projects with a very large flow and pressure requirement where redundancy is important

- Duty/Assist/Assist/Assist

- This is suitable for projects with a very large flow and pressure requirement where redundancy is not the priority

As you can probably imagine based on the above list, any pump configuration is possible.

However, whilst adding more pumps does improve the reliability and efficiency of the system, the installation becomes increasingly expensive.

What is the best location for the booster pump?

Booster pumps need to be located before (also known as upstream) every fixture that needs pressuring.

- For medium or high-rise buildings:

- Located on the incoming supply to the building

- When there is a water storage tank:

- Located directly on the outlet of the storage tank

Design communication

Whilst the booster pump is part of the plumbing system, it requires various members of the design team to allow for it in their own design.

If you do not communicate the various requirements to the rest of the team, they will not provide their services to it. This means there will be issues that need to be resolved later in the design stage, which will have significant consequences.

Electric requirements

Provide the electrical engineer with the power requirements and location of the booster pump.

The power supply will ensure the booster pump is able to operate.

BMS requirements

Provide the mechanical (or sometimes electrical) engineer with the BMS requirements of the pump.

The BMS monitoring will inform the maintenance team of any issues with the pump by providing warnings to a central location.

Weight

Provide the structural engineer with the booster pump weight to ensure their structure is designed to handle it.

Space requirements

The size and location of the booster pump need to be coordinated with the architect.

There should also be sufficient clearance around the pump for maintenance and a viable path in and out of the building in the event of it needing to be replaced.

Booster pump maintenance

Compared to other major components of a water system, booster pumps generally require minimal maintenance.

Maintenance is usually undertaken annually, which consists of:

- Visually inspect for any leakage

- Visually inspect the pressure gauges

- Visually inspect the pump (impeller, seals, bearings, valves, volute) for signs of degradation

- Check the pump’s foundation to ensure the frame is secure

- Check the electrical components are in good condition

- Check that all BMS points are operating correctly

The pumps will need to be replaced eventually; their design life is around 15 years.

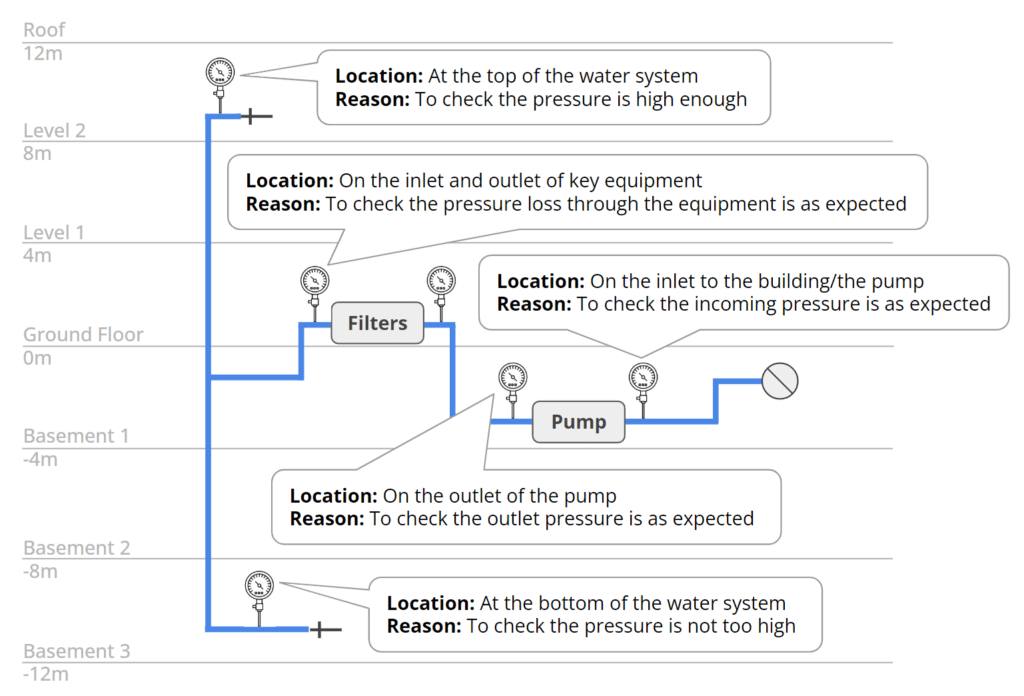

Pressure gauges

It is good practice to install pressure gauges in various locations around the water system.

Some example locations of where to locate pressure gauges are:

- On the incoming water supply

- On the inlet to the pump

- On the outlet of the pump

- At the top of the building

- At the bottom of the building

- On the inlet of key equipment

- On the outlet of key equipment

The pressure gauges provide you with the ability to check the pressure in various locations around the building.

As you can see in the image above, if you found an unusual pressure reading at a point in the system, you could check the various gauges around the system to troubleshoot where the issue is coming from.

Without the pressure gauges, it would be difficult, time-consuming, and intrusive to troubleshoot the problem.

This allows you to easily undertake fault finding and ensure the pump is operating as intended.

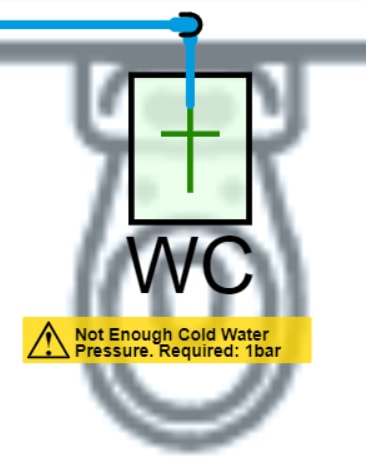

h2x automates your pressure calculations based on the inputs from the water connection, the water system layout, and the heights assigned to your fixtures/nodes.

Warnings are provided where the pressure falls short of the component(s) minimum inlet pressure.

And the booster pump duty is automatically sized when you add a pump to your design.

H2X was built by engineers to help engineers work faster and more accurately.

If you would like to try H2X today, sign up for a 14-day free trial now.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP