10 Steps to Creating an Easily Maintainable System

This one should go without saying... but a correct design is crucial for maintenance because it ensures that the system functions efficiently and effectively, minimising the likelihood of breakdowns, complaints, and the need for repairs.

Download your free PDF of this article below.

1 – A Correct Design

This one should go without saying… but a correct design is crucial for maintenance because it ensures that the system functions efficiently and effectively, minimising the likelihood of breakdowns, complaints, and the need for repairs.

On the other hand, a poorly designed system can lead to a variety of maintenance problems, such as leaks, which can be expensive and time-consuming to repair.

Additionally, an inadequate design can result in issues like poor water pressure and noise, which impact the overall functionality of the system and will need to be repaired.

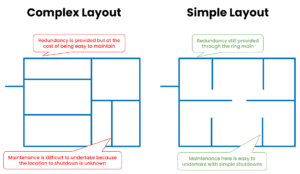

2 – A Simple Layout

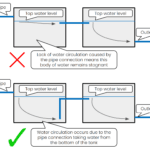

A simple layout is important for maintenance because it can make it easier to identify and locate problems.

When a layout is complex, with many twists and turns, it can be more difficult to pinpoint the exact location of a blockage, leak, or other issue that requires attention. This can lead to delays in repair and higher maintenance costs.

A common problem for the maintenance team is when there is an interconnected ring main around the site or building, which makes it very difficult to shut off a water supply.

In contrast, a simple layout is easier to navigate and maintain.

3 – Clear Drawings

Clear and accurate drawings are important because they provide essential information about the layout and components in the system.

With clear and accurate drawings, maintenance personnel can easily locate components of the system. This allows them to quickly identify the cause of a problem and take the appropriate steps to resolve it.

Additionally, detailed drawings can help maintenance personnel to understand the relationship between different components of the system, such as the flow of water or the pressure at different points in the system. This can help them to identify and correct problems more effectively.

Without clear and accurate drawings, maintenance personnel may have to spend more time searching for components, determining the system’s layout, and identifying the cause of a problem. This can result in longer repair times, increased costs, and potential safety risks if the system is not functioning properly.

4 – Reliable Materials

Reliable materials are important because they give the system the best chance to operate efficiently and effectively over the long term. High-quality materials are less likely to corrode, leak, or break down, reducing the need for maintenance and repair over time.

When components are made from unreliable or low-quality materials, they may not withstand the pressure, temperature, or chemical exposure that they are subjected to over time.

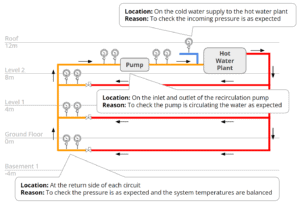

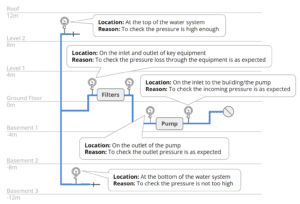

5 – Fault Finding

Temperature and pressure gauges are important for fault finding in systems because they provide essential information about the condition of the system.

These gauges measure key parameters such as temperature, pressure, and flow rate, which can help maintenance personnel identify potential problems and take appropriate corrective action.

Temperature gauges can help identify issues such as poor recirculation, which can indicate a high risk problem with the hot water system.

Similarly, pressure gauges can help identify issues such as low water pressure, which may indicate a leak, a blockage, or a problem with the pump or pressure tank.

Temperature and pressure gauges can also help maintenance personnel to identify changes in the plumbing system’s performance over time. By monitoring these parameters regularly, they can identify trends or patterns that may indicate a developing problem, allowing them to take corrective action before the problem becomes more serious.

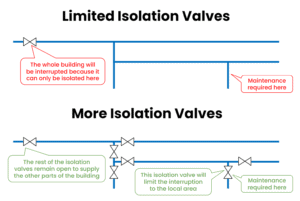

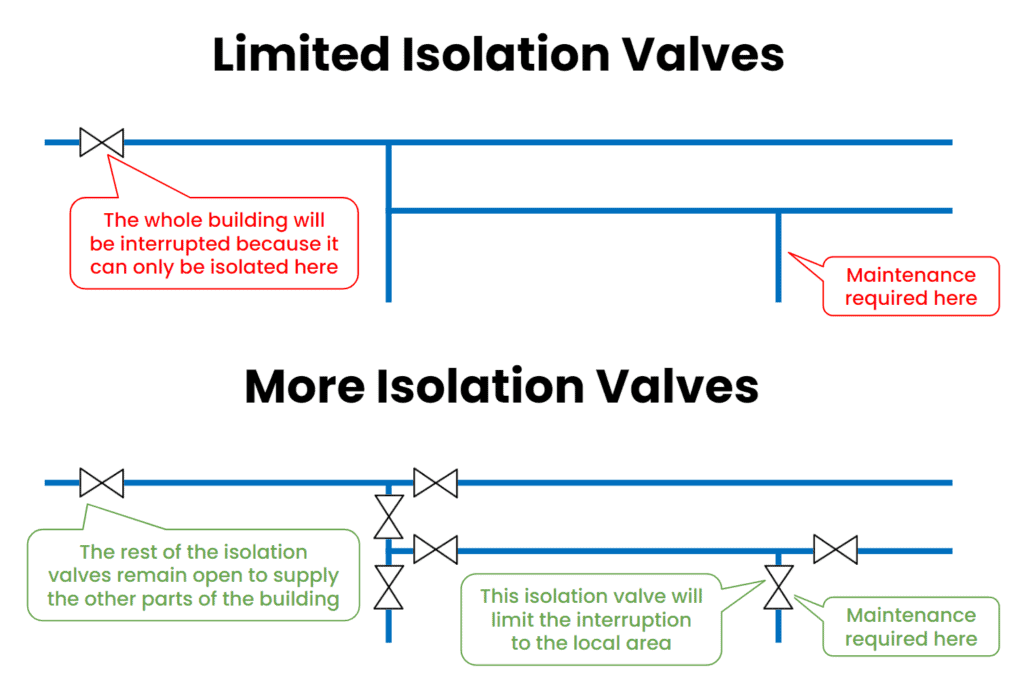

6 – Isolation

Isolation valves are important for maintenance because they allow maintenance personnel to isolate a specific section of the system for repair or maintenance without having to shut down the entire system.

By using isolation valves, maintenance personnel can work on a particular section of the system while keeping the rest of the system operational.

Without isolation valves, maintenance personnel would need to shut down the entire system to work on a specific section. This can be time-consuming and disruptive, especially in larger or more complex systems.

Additionally, shutting down the entire system may not be practical or feasible in some situations, such as in healthcare or industrial settings where the system needs to remain operational.

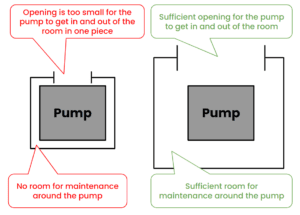

7 – Access

Space to Maintain

Providing space around equipment is important because it allows maintenance personnel to access and work on the equipment safely and effectively.

Some equipment requires regular maintenance and without adequate space, maintenance personnel may struggle to access and work on the equipment, increasing the risk of accidents and damage to the equipment.

In addition to safety concerns, providing space around equipment also helps to improve the efficiency of maintenance operations. When maintenance personnel have easy access to equipment, they can work more quickly and efficiently, reducing downtime and minimising disruptions to the plumbing system’s operation.

Paths of Travel

Without clear paths of travel, maintenance personnel may have to navigate around obstacles, increasing the risk of accidents or damage to the system.

It can also prevent major components from being brought in or out of the building in one piece, requiring extra work for it to be assembled/disassembled on site.

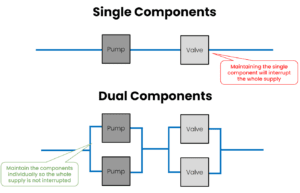

8 – Redundancy

Redundancy is important for maintenance because it helps to ensure that the system remains operational even if a component fails or requires maintenance.

A redundant system is one that has multiple components that perform the same function, so if one component fails, another can take over its function, allowing the system to continue operating.

In a system, redundancy can be achieved through the use of duplicate pumps, valves, or other critical components. By providing redundant components, the system can continue to operate even if a component fails or requires maintenance. This helps to minimise downtime and reduce the risk of damage or disruption to the system’s operation.

Redundancy is particularly important for critical systems, such as those used in hospitals, data centers, or other facilities where downtime can be costly or even life-threatening. In these settings, redundant systems help to ensure that critical operations can continue even if a component fails or requires maintenance.

9 – Backup Supplies

Backup water and power supplies are important for maintenance because they help to ensure that the system can continue to operate even in the event of a power or water outage. Without backup supplies, a power or water outage could result in a disruption or failure of the system, which could be costly or even dangerous in certain settings.

In the case of power outages, backup power supplies, such as generators or batteries, can be used to provide electricity to critical system components, such as pumps or valves.

Similarly, backup water supplies, such as storage tanks, can be used to ensure that the plumbing system has an adequate supply of water in the event of a water outage. This can help to prevent damage or disruption to the system’s operation, particularly in settings where water is critical, such as hospitals or data centers.

10 – Maintenance

Regular maintenance is important because it helps to ensure the continued reliability and efficiency of the system over the long term.

Regular maintenance can help to identify and address potential problems before they become more serious, reducing the risk of damage or disruption to the system’s operation. It allows maintenance to be planned rather than reactive.

Regular maintenance can involve a variety of activities, such as inspecting and cleaning equipment, checking for leaks or other signs of damage, and replacing worn or damaged components.

Regular maintenance can also help to extend the lifespan of system components, reducing the need for premature replacement and minimising overall maintenance costs.

By identifying and addressing potential problems early on, maintenance personnel can help to prevent more serious damage from occurring, reducing the need for costly repairs or replacements.

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems mean that you can focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo with us today to discover how h2x can help you improve your design and calculation workflow.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP