Designing RPZ Backflow Prevention Valves

As an example, if you were connecting a potable water supply to the HVAC system, this would require backflow prevention because of the chemicals used in the HVAC system.

Why are they required?

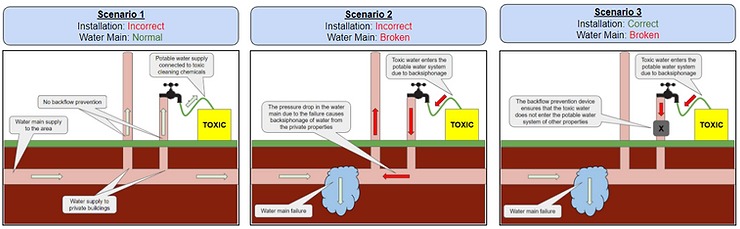

As an example, if you were connecting a potable water supply to the HVAC system, this would require backflow prevention because of the chemicals used in the HVAC system. If the chemicals that are used in the HVAC system were able to enter the potable water supply, consumption of that water would pose a significant risk to public health.

A medical centre in Midwest U.S. saw the deaths of two patients who had unfortunately consumed water that was supposed to be potable (safe to drink). As there was no RPZ on the potable water supply to the HVAC holding tank where chemicals were mixed, when backflow occurred in the system, the chemicals made their way to the outlets of the basins and sinks throughout the medical centre.

How does backflow occur?

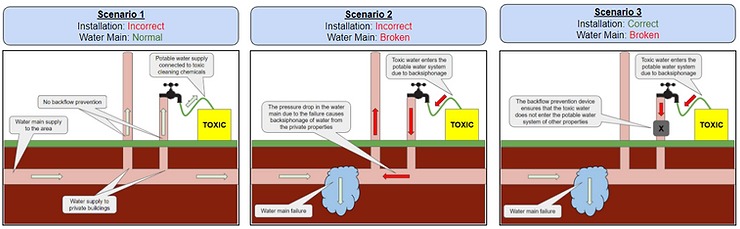

Backflow is the reversal of the intended direction of water flow. This occurs when there is a significant drop in pressure in the upstream water supply which is commonly caused from water main failures.

The image below shows how backflow can occur as a water main fails and also highlights the consequences when backflow prevention is not installed correctly. As shown, the water main fails and there is no backflow prevention installed to stop the toxic chemicals entering the ‘potable’ water supply to other buildings.

Sizing of RPZ Valves

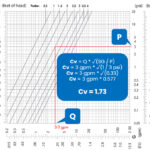

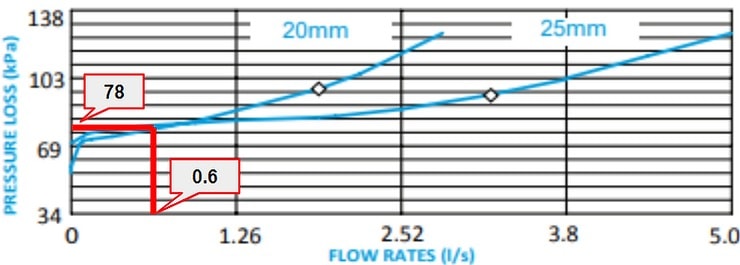

Manufacturer’s usually have an easy to read graph that will enable you to quickly determine the correct RPZ valve size and the corresponding pressure loss. Note the RPZ does not always need to match the pipe size on the inlet to the RPZ.

As you can see in the example below, if you have a flow rate of 0.6 l/sec (25mm pipe at a 1.5 m/sec maximum velocity), you can use either a 20mm or 25mm RPZ valve and experience a similar amount of pressure loss.

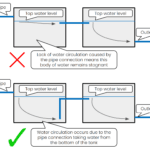

Fixtures used for Personal Hygiene

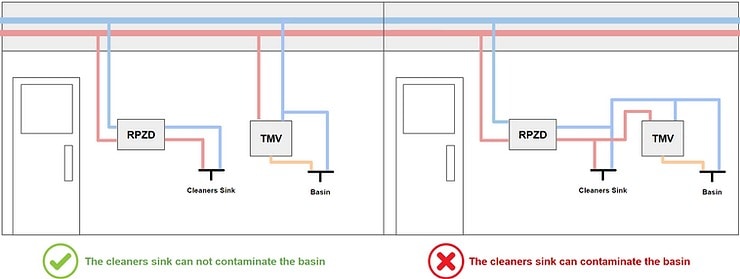

An honest mistake that is commonly made is connecting fixtures that are used for personal hygiene downstream of the RPZ because it is in the same room. This results in a design that is not fit for purpose and it is also non-compliant.

In the example below, there is a cleaners room that has a sink (used for mixing chemicals) and a basin (used for personal hygiene).

The sink requires the RPZ to prevent the chemicals entering the potable water supply. However, if you connect the basin downstream of the RPZ too, the design will allow chemicals to come out of the basin where someone expects it to be potable and could therefore potentially consume.

Draining of RPZ Valves

RPZs discharge water, that is what they are designed to do in some circumstances.

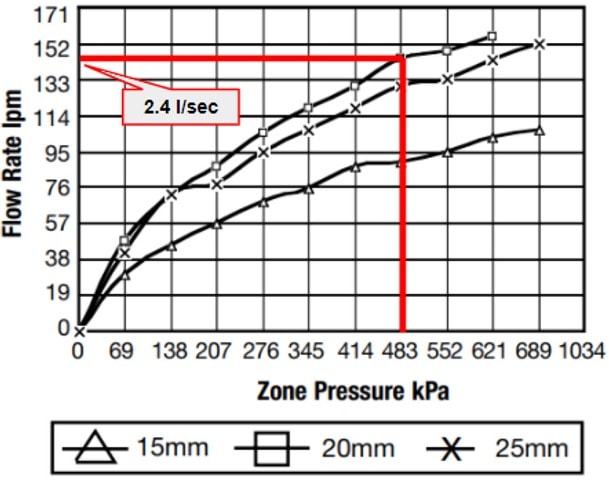

Manufacturers will be able to provide you the relevant graph to determine how much water you can expect to discharge so that you can size the drain accordingly.

They discharge more than you expect and you need to have a sufficient drain below the RPZ valve to cater for it. In the example below, a 20mm RPZ with an incoming pressure of 483 kPa will discharge 2.4 l/sec.

Check out this video to see a discharging RPZ in action.

Maintenance

Regular maintenance is required for RPZ valves to ensure they operate correctly on an ongoing basis. With this in mind, it is important to design with the following considerations:

- Provide dual RPZ where the water supply is critical and should not be shut down routinely e.g. in hospitals

- Locate the RPZ in an accessible position i.e. do not install it too high, do not install it too low, and do not install behind permanent furniture

Miscellaneous Items

Some other items that should be considered in a design are:

- A strainer should always be provided (it is usually required by the regulations) upstream of the RPZ to protect the valve from damage

- When RPZ valves are located internally, it is important to coordinate their locations with the architect as they are relatively large and not too aesthetic

- There are alternative options to an RPZ valves which may be suitable and more cost effective where the risk of cross contamination is not high

- ‘Warning – Not for Drinking’ stickers should be provided at fixtures supplied by RPZ valves

Are there any other important design items that you would like to see included in this article? Let us know in the comments.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP