Water Surge Protection from Flowtech

Flowtech Water Solutions are experts in water services and water booster sets. They supply a wide range of standard and custom products across the UK. After partnering with h2x, they have shared their extensive knowledge in Water Surge to benefit h2x’s audience of engineers.

What is Water Hammer or Water Surge?

Water hammer can happen to any system that has pipework utilising valves, pumps, etc that allow for the control of water flow (or other liquids) throughout a building.

The sudden closing of a valve, water hitting a dead end or a sharp bend, can cause a high-pressured shockwave. This surge will travel throughout the pipework, as the liquid is forced to stop or change direction quickly.

In most cases, the surge in the pipework can be heard straight away and sounds like knocking or banging of pipes. In extreme cases, the pressure surge can break the pipework itself.

Suggested reading: Read our article, Booster Pumps to learn more about designing and sizing Booster Pumps.

Risks to High-Rise Buildings

For high-rise buildings, the effects of water surges can be quite damaging and pose a serious risk.

Each high-rise building will have at least one riser. This is the main pipework from the basement to the top floor, which connects to smaller distribution pipework on each storey.

If the pump is caused to stop operating, maybe due to a power cut, engineer’s works, or a fault in the system. The water pressure in the building would gradually decline as outlets are opened and the remaining water in the system is drained under gravity.

As this water is coming out of the outlets, this can create a vacuum in the pipework, depending on whether there are nonreturn valves or pressure-reducing valves in other parts of the system.

When the power is restored the pump begins to operate again and restores system pressure to pre-set levels. If the unit is specified correctly, it should have a comprehensive “soft fill mode” to gradually fill the system at a controlled rate.

On poorly controlled units, that do not have such a mode of operation, water hammer will be almost unavoidable.

The worst case is that this pressurised water is pushed into a vacuum and the water will accelerate beyond expected design velocities. This can be due to multiple pumps running and possibly pumps running that are designed as a “standby”.

This will cause a hydraulic shock to the pipework potentially beyond the test pressure of the system. These high pressures can cause weak pipework or connections to burst, causing potentially huge flooding and expensive water damage within the building.

Not only is this expensive to fix, it means downtime to the building’s water supply. It is also a serious health and safety risk to those people that occupy the building at the time of the burst.

Remedies for Water Surge

So, what can be done to avoid this?

Ensuring you have a booster set with a surge protection feature is a great precaution, so when the pumps are powered back up, they are limited to one pump and gradually increase their pressure to avoid ramping up too quickly.

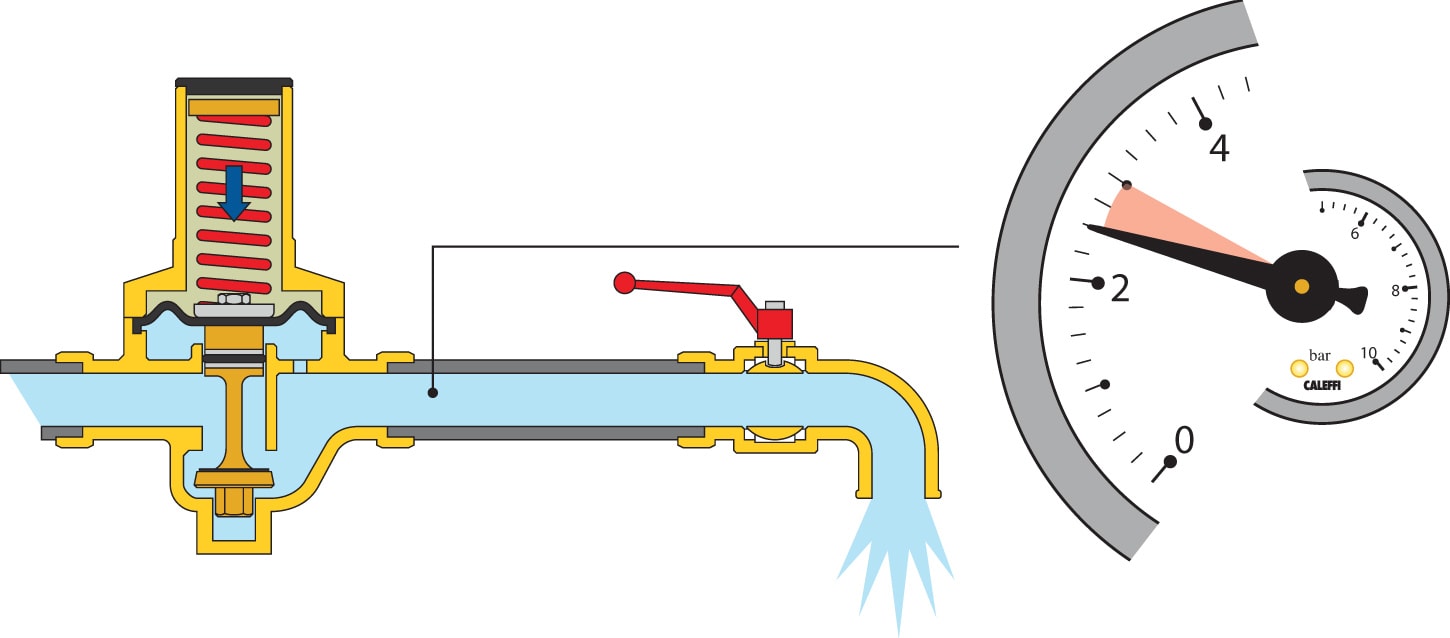

As well as this, an Air and Water Protection Valve can be installed at the top of each riser.

This device not only avoids vacuum being created, it also forces air through the “anti-surge” orifice when the system is filling which allows for the deceleration of the incoming water supply, thanks to the resistance created by rising air pressure in the AWSPV valve.

This softens the potential pressure spike when the AWSPV valve finally closes.

“The AWSPV valve design, ensures effective de-aeration under all pipeline flow and operating conditions, via either one of three discharge orifices.”

Once the system is full and free of air, the valve seals. The valve must be piped to a drain or safe area to ensure any leaks are discharged to a visible position.

Design with Flowtech Products

h2x has collaborated with Flowtech so that customers in the UK can design using Flowtechs product range.

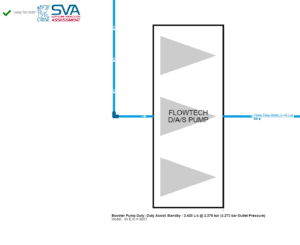

When users add a booster pump, h2x will calculate the required pump duty:

Flow Rate – calculated by the number of fixtures/nodes connected to the pump

Pressure Drop calcuator – calculates the pressure by meeting the ‘Minimum Inlet Pressure’ at every fixture/node

Then, based on the configuration that you select (Duty/Standby or Duty/Assist/Standby), H2X will provide the relevant Flowtech Flowboost model to suit your project.

As shown in the image below, a ‘Duty/Assist/Standby’ pump which requires a flow rate of 2.42 L/s and an extra 2.372 bar of pressure will specify the relevant Flowtech Model – 3V.E.K.H.3007

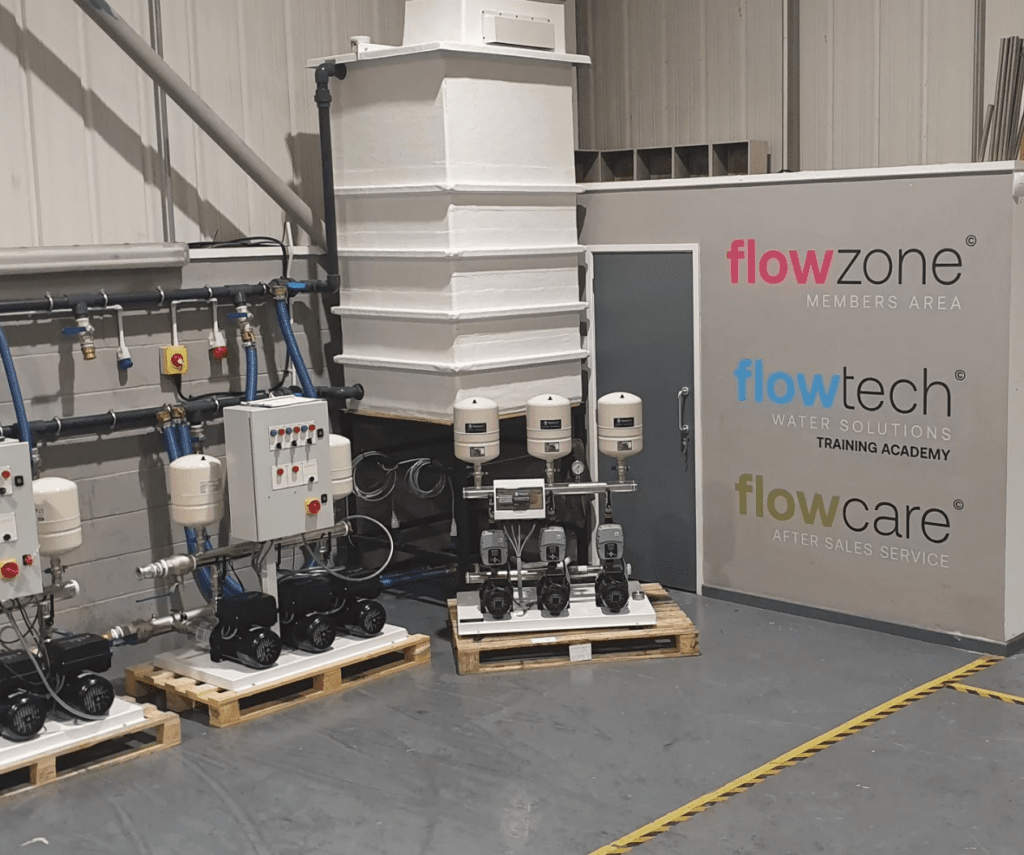

Flowpac Compacts

The Flowpac Compact range is an integrated booster pump and storage tank combination, which offers the maximum in space saving solutions for boosting water in large domestic and commercial premises, available with AG Air Gap for potable applications and AB Air Gap for CAT5 applications. Standard tank sizes from 600 litres designed to fit through standard doorway to 3000 litres with other sizes on application.

Every unit is completely assembled, wired and tested prior to despatch minimising the time on site for installation. This is especially important when the new set is replacing an existing unit where down time must be kept to a minimum.

Flowtech also offer a two- or three-piece tank allowing the set to be dismantled prior to arriving on site and then taken piece by piece to the plant room and then reassembled in the room.

All Flowpac Compact Booster Sets are available in bespoke sizes and are designed to meet the requirements of the water regulations.

Flowtech & h2x Product Integration

Watch the video below to learn how the Flowtech product integration works in h2x.

Calculation software that empowers engineers

h2x is a plumbing system design software built to ensure compliance, efficiency, accuracy and collaboration.

Its straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo with us today to discover how H2X can help you improve your design and calculation workflow.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP