MM Kembla

MM Kembla

Established in 1916 and operating for over 100 years, MM Kembla is Australia’s only copper tube manufacturer and still manufactures over 87% of the copper tube lengths it sells from its original site at Port Kembla, NSW. MM Kembla remains one of the most highly regarded suppliers of integrated piping system solutions for Plumbing, HVAC-R, Medical and Industrial applications. MM Kembla’s range of integrated piping system products reduces risk during and after installation. There’s peace of mind with one brand, one system and one warranty solution to your next project

Whilst you may not see our products work behind walls, MM Kembla has been responsible for providing clean drinking water, heating and cooling, warm showers and critical medical gases to homes, offices and hospitals across Australia, New Zealand, South East Asia and the Middle East for over 100 years.

That’s over 100 years of manufacturing know-how and development of in-house technologies like KemCore. The use of KemCore Technology manages tube concentricity across its entire length, ensuring all copper tube produced in Australia is the most concentric tube on the market by providing uniform wall thickness and optimal performance when used with press fittings.

KemPress with KemGuard Technology

MM Kembla’s KemPress Press-Fit system now incorporates KemGuard Technology. KemGuard technology is a unique set of features that improves installation quality, minimises risk during and after installation, provides identifiable cues for incorrect installation and provides the ability to manage and monitor on-site performance.

This suite of risk minimising features now includes “Un-pressed Fitting ID” to assist in identifying un-pressed fittings. Utilising a combination of O-ring design and fitting tolerances designed to allow water or air to escape an un-pressed fitting via a low-pressure test.

Learn more about KemPress with KemGuard Technology via our explainer video https://youtu.be/nnIMmrk3OH4 or contact your MM Kembla representative Ali Rad for more details.

Copper Press-Fit: The cost of not making the switch

Studies show that Copper Press-Fit is 21% faster and 10% cheaper than copper brazed fittings, allowing your business to secure future opportunities and increase profitability.

Since its release to market, the speed and safety benefits of Copper Press-Fit over traditional copper brazed fittings have been increasingly recognised across the plumbing industry with more and more plumbers adopting Press-Fit technologies to maintain a competitive advantage.

A recent study into the cost of various plumbing systems, commissioned by the International Copper Association Australia and conducted by the highly regarded Mr Nigel Essex of SX Estimates, further supports the advantages of Copper Press-Fit over brazed fittings. Through the comparison of total resource cost and time, the study has highlighted some positive implications on opportunity costs for your business.

The Study

The study was undertaken by an independent plumbing system estimator, Mr Nigel Essex of SX Estimates from Sydney, to compare the costs of different plumbing systems for a medium-size commercial building. The estimates were based on the use of copper plumbing systems incorporating silver brazed fittings and Copper Press-Fit fittings on a typical 175 room, 10 story hotel. The costs of both labour and materials were based on average commercial market material purchase and labour cost rates.

Cost

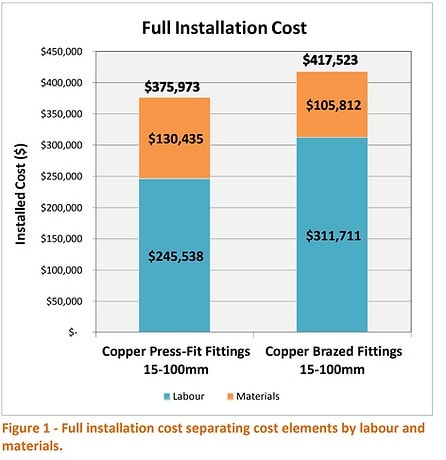

Figure 1 shows the result of the comparison between the Copper Press-Fit and brazed fitting methods, separating the cost elements by labour and materials.

As often argued by conservative plumbers, the initial material costs of using Copper Press-Fit are at present more expensive; too often acting as a deterrent when considering options for fittings.

However, as a result of the comparative cost of labour being a significant 21% cheaper than the cost of labour for brazed fittings; the overall installation cost when using Copper Press-Fit fittings is 10% cheaper than when using the traditional method.

Time

Time management and increased productivity is the key to the success and profitability of a plumbing business. Poor time management and low productivity create a negative impact on a project environment, particularly through increased cost, loss of future job opportunities, loss in profit and damage to reputation.

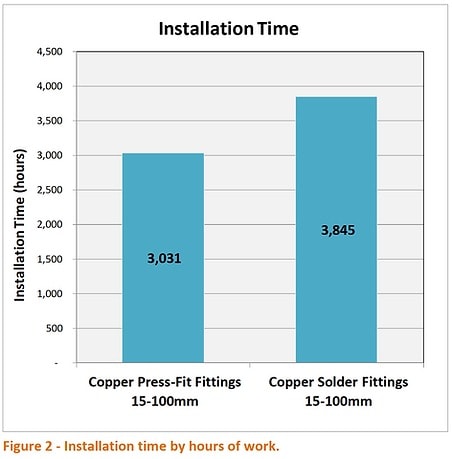

Figure 2 compares the installation time by hours of work between Copper Press-Fit and brazed fittings and clearly shows the installation time for Copper Press-Fit fittings as a substantial 21% faster than using brazed fittings.

When analysing this data into 8 hour working days, the hours saved when using the Press-Fit technology amount to 102 working days. That is valuable time that could be allocated to your future job opportunity.

Market feedback has reported average installation times to be at least 30% faster than brazed fittings, further supporting the speed benefits of adopting Copper Press-Fit.

Opportunity Costs

The ability to allocate labour resources as quickly as possible to the next project is imperative to the success of any business in the construction industry and should be a key consideration in choosing material for your plumbing system. In this example, being able to feasibly allocate more than 100 days to another project is invaluable to the productivity and profitability of your business.

Furthermore, with at least half of the Australian market still using copper brazed fittings, one of the biggest opportunities in utilising Copper Press-Fit technologies lies in the ability to differentiate your business in a competitive environment. Utilising the latest technology and being able to offer a shorter project schedule than your competitors is a competitive advantage that will not only improve your reputation but in turn allow you the opportunity to secure further work for your business.

Make the switch to Copper Press-Fit today for a faster and more cost-effective option to traditional brazing and a welcome boost to your business’s reputation and financial performance.

For more information on the KemPress® Copper Press-Fit system visit www.kembla.com.au.

Introducing MM Kembla BIM Solutions

MM Kembla BIM Solutions provides easy-to-use Revit content so you can design and document a range of MM Kembla pipes and fittings as part of MM Kembla’s integrated piping system offering – including the renowned KemPress Copper & Stainless systems, Kembla Copper Tube and much more. Access individual Revit files or try out the virtual showrooms so you can include Kembla products in your next project.

Check it out now at: https://www.kembla.com/kemspec/mm-kembla-bim-solutions/

Did you know?

You can design water and gas systems using Kembla’s Copper Press-Fit in H2X.

Test it out for yourself by starting a free trial here.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP