Stainless Steel or Copper Pipes? By Allmach

Does a stainless steel pipe outperform copper?

For years, copper has been the de facto standard for transporting drinking water into buildings.

As science and technology evolve, we often see things in a new light, whether it’s research into health, environmental factors or the evolution of products.

Given this, it’s worth reviewing copper’s use in water transfer solutions and seeing whether there are better options.

In this article, we look at some facts about stainless steel piping and ask the fundamental question:

Is it time to retire copper piping solutions for good?

The case for stainless steel piping over copper

When looking at a piping solution for water and gas transfer, we need pipes that tick all the relevant boxes – strong, sustainable, hygienic, and easy to work with.

As Engineers, we need to be satisfied with the performance properties, but also need to be cognisant that our clients also want a cost-effective solution.

How do the two compare in terms of strength and durability?

Copper is a soft and highly malleable material. This feature can be beneficial in some applications; however, it can pose numerous issues in large water and gas installations. Copper is also more susceptible to damage from external knocks during storage and installation.

Stainless steel is more rigid and 40% stronger compared to copper. Stainless steel doesn’t need as much support as copper because it has greater tensile strength and is 9% less susceptible to thermal expansion on average. It is calculated to reduce bracketing requirements by up to 40%.

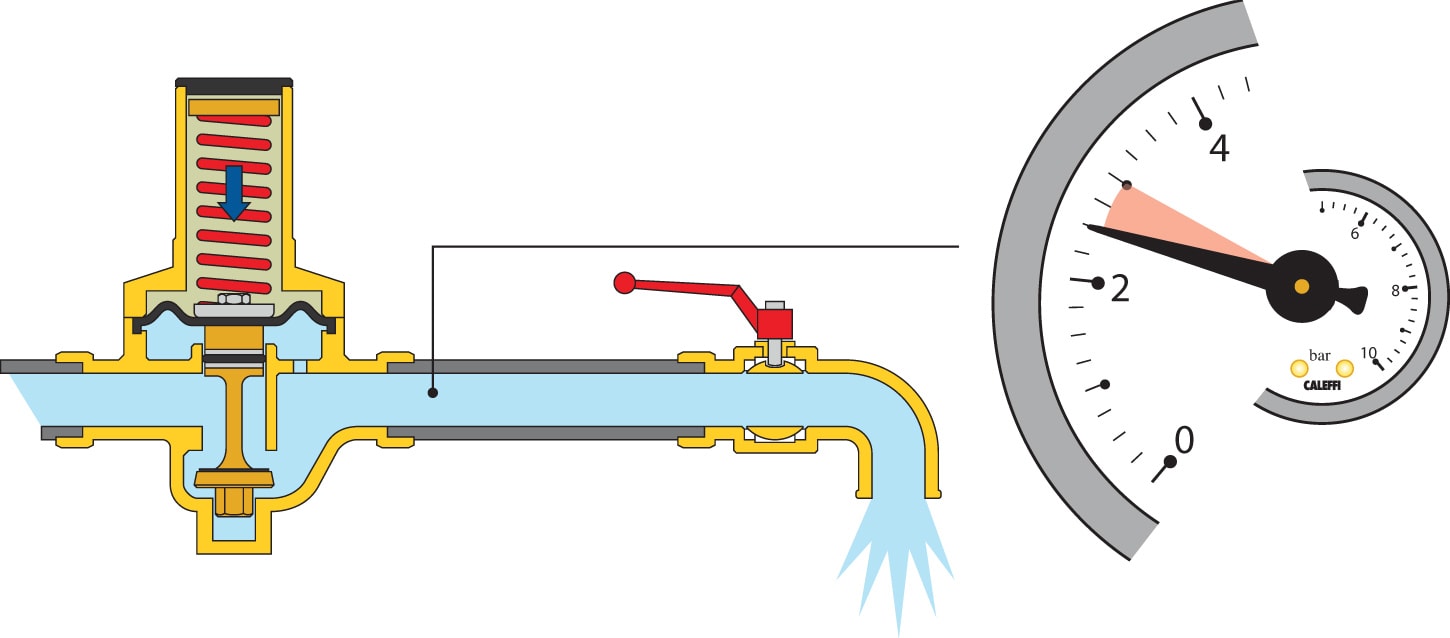

Stainless steel can also withstand high-pressure ratings of up to 4000kpa. Copper’s pressure rating reduces dramatically as the size of the pipe increase, making it unsuitable for high-rise buildings.

How do the two compare in terms of cost?

When comparing the cost of raw materials for piping systems, copper and stainless steel have unique advantages and disadvantages. Copper tends to be susceptible to higher cost fluctuations in its raw state, especially in larger sizes.

There is also the issue of welding joints and hot work permits. While some copper pipe joints can be crimped using a press-fit tool, copper sizing is limited to 100mm in press-fit fittings. Conversely, stainless steel press-fit pipes can reach 168mm.

Although press-fit copper can cost approximately 10% less than stainless steel at 15mm, research shows that the cost advantage diminishes as the pipe size increases. For instance, at 28mm, copper costs around 19% more; at 54mm, it costs 22% more; and at 108mm, it costs 24% more. Braised copper typically costs less, but its higher installation cost offsets this.

Theft is a hidden cost as both households and commercial properties can be targeted, where stolen copper is sold for scrap at recycling yards. As long as copper prices continue to rise worldwide, so too will the instances of copper pipe theft.

How do the two compare in terms of sustainability?

Sustainability is another essential factor to consider when selecting materials for piping systems. Stainless steel is a more sustainable option with a low carbon footprint due to its production process without harmful chemicals.

It is also manufactured using a high proportion of recycled material and is 100% recyclable. In contrast, copper is shown to cause problems when recycling, notably as an end-of-life recycling constraint.

How do the two compare in terms of use cases?

Fluids

Another constraint on copper is that it cannot be used in specific applications, such as pipework carrying diesel fuel, where copper can cause diesel to polymerise and thicken.

Pressure

Moreover, the pressure rating of copper pipes reduces dramatically as the size increases.

Velocity

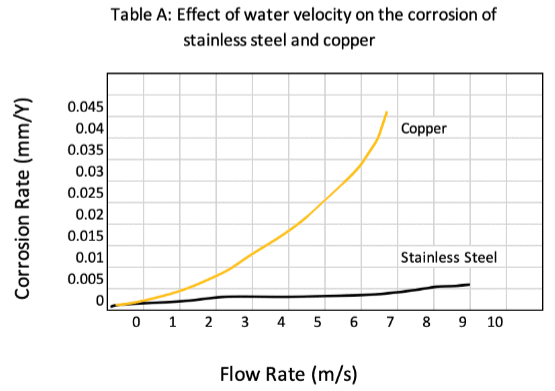

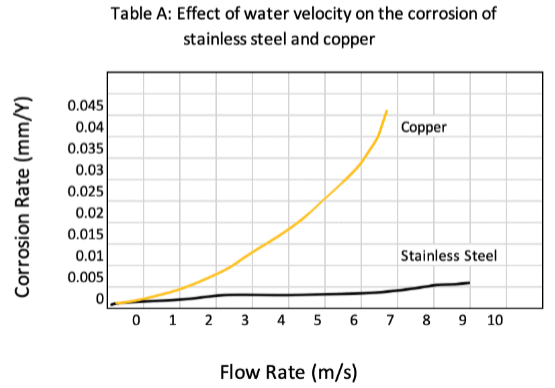

High-velocity systems cannot use copper pipes due to the risk of corrosion, which increases as the flow rate and temperature increases.

Are there positive health impacts of using stainless steel instead of copper piping?

Over the last ten years, research has uncovered that copper ions are released into drinking water where the copper pipe is used.

Studies by the European Commission into which type of pipe had the least emissions leaching into drinking water found that stainless steel fared much better than copper.

While humans can absorb some amounts of copper without adverse health impacts, the older the copper pipes are, the higher the concentration of copper ions released into drinking water through corrosion.

People who come into contact with copper through working with the material or consuming copper ions leached into their drinking water can lead to copper fever, a flu-like condition, and in large quantities, copper poisoning.

Stainless steel does not promote the growth of “biofilm”, which is an essential element for the development of bacteria, whereas copper does.

Another benefit of stainless steel is in the material itself. It has a smooth, hard oxide layer making it hard for bacteria and microorganisms to hide in. Copper’s topography has a surface that promotes bacteria growth as it is easier for the bacteria to find shelter in the material.

Just as copper replaced the use of lead before, likely, stainless steel will eventually replace copper as the material of choice when it comes to function, form and health standpoint.

In many parts of the world, including Switzerland, Germany, Italy and Denmark, the appetite for copper piping is decreasing and being replaced by stainless steel as the material of choice.

Do we need to examine flow rate, and if so, why?

Flow rate is crucial in piping solutions because it determines how much fluid or gas can be transported through the pipeline, it affects pressure and velocity, and impacts the overall performance and reliability of the system.

Proper consideration of pipe diameter, valve size, and pump capacity is necessary to ensure the required flow rate is achieved while maintaining essential pressure and flow conditions.

Stainless steel is corrosion-resistant and is protected by forming a self-repairing passive oxide film. On the other hand, copper is prone to oxidation, leading to corrosion over time.

Additionally, the surface of copper is 17% rougher than that of stainless steel, making it more susceptible to structural corrosion at higher water flow rates.

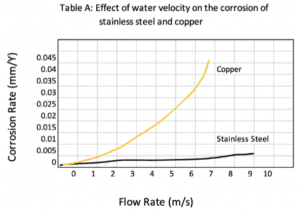

Water flow above 2 m/s causes structural corrosion in copper. Stainless steel is corrosion resistant, given it takes 6 m/s (which is above the allowable velocity in the Standard) to affect the inner wall of stainless steel, leading to greater efficiency with increased structural integrity.

The graph below shows how water velocity impacts the corrosiveness of the pipe over time. We can see radically different results when comparing copper versus stainless steel piping:

Source: https://blog.waterworksnz.co.nz/stainless-steel-piping-vs-copper-piping

Do we need to examine heat transfer, and if so, why?

Engineers understand that heat transfer is critical in piping solutions as it affects the system’s performance, efficiency, and safety.

Proper heat transfer management is essential to maintain the desired fluid temperature, prevent overheating, and minimise energy losses.

Heat transfer can occur through conduction, convection, or radiation, impacting the piping system’s material selection, insulation, and design. Therefore, understanding and controlling heat transfer is crucial for engineers designing or maintaining piping solutions.

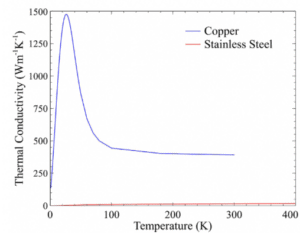

Stainless steel has a lower heat conductivity ratio than copper, making it less susceptible to heat loss. On the other hand, copper requires more insulation to prevent heat loss. Stainless steel’s thermal conductivity is 1/25th that of copper, making it a better choice for applications where heat transfer needs to be minimised.

Source: https://www.researchgate.net/figure/Variation-of-thermal-conductivities-of-copper-and-stainless-steel-with-temperature_fig4_319575524

Case study: Installation of Surepress Stainless Steel press-fit solution for the NSW Maitland Hospital build

The NSW Government commissioned a new hospital build to service the communities of the Hunter Valley NSW and its surrounds, with a project budget close to $500 million.

The Project team and Engineers needed a world-class solution to deliver hot and cold water and gas throughout the hospital’s underlying infrastructure. The brief was to deliver the solution cheaper without compromising on quality and providing a safe work environment at the same time.

Allmach’s Surepress press-fit stainless steel pipe, fittings and custom-fabricated manifolds were chosen to deliver an impressive 15 km of stainless steel pipe.

Being a press-fit installation, safety and expediting of the install were done without the need for hot work permits. Quality assurance procedures were met using the Surepress press-check sleeve film visual confirmation and leak path O-rings. Having a visual quality confirmation made the installation easier and faster, with the comfort of peace of mind the joints were leakproof. The guarantee is an inherent feature of the press-fit solution.

The Surepress system is corrosion-proof, leak-proof and has wash-down properties. The Surepress 316L stainless steel press-fit system made the gas and water pipe installation faster, easier, and safer than traditional copper pipe, saving significant time and money.

The installers could crimp Surepress fittings up to 168mm, an advantage over the copper pipe that can only be crimped up to 100mm – anything larger would need welding.

With extended lengths of service piping throughout supporting the hospital’s infrastructure, the installers avoided extensive bracketing to keep the pipes, as would have been needed with copper piping. The strength and rigidity of our stainless steel pipes were another project that saved installation time and cost, recognised by the construction and installation teams.

Using stainless steel press-fit, the installation saw results 10x faster than conventional welding. This reduced installation time, cutting overall costs by under 30%.

Conclusion

In summary, we have seen the facts and benefits of a press-fit stainless steel piping solution – it outperforms copper in every aspect, from velocity and ease of installation to time and cost savings, all done to the highest quality control standards.

We’ve also seen examples of how some European countries increasingly choose stainless steel over copper for the positive health benefits of stainless steel piping.

Allmach is an Australian piping systems supplier focusing on sustainable infrastructure delivery and innovative solutions, including leak detection.

Allmach is ISO9001 certified and is a major wholesaler and distributor of PVC, Polyethylene, Carbon Steel & Stainless Steel, Aluminium, and pipe, fittings and valves, suitable for the delivery of mains water, wastewater and water treatment, in particular chemical dosing and aeration.

Allmach’s Surepress press-fit piping solution is backed by a 25-year manufacturer’s guarantee, uses AS5200-compliant stainless steel, and is AGA, ActivFire and WaterMark certified.

h2x has collaborated with Allmach so that customers in Australia can design stainless steel piping systems using their product range.

You can learn more about h2x’s design software below.

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems mean that you can focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo with us today to discover how h2x can help you improve your design and calculation workflow.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP