Sizing Hot Water Plant from Rheem

Includes a worked example of TankPak sizing.

Rheem are the experts in hot water sizing and has teamed up with H2X to make selecting hot water plant available at your fingertips.

The following hot water plants are available on the H2X site:

1. Individual continuous flow gas water heaters (CFGWH)

2. The popular Tankpak range of manifolded CFGWH with storage

3. Commercial air to water (A2W) heat pumps with a range of storage tank options

4. Heavy-duty electric storage water heaters

The sizing and selection of plant depend on the application type.

Generally, individual CFGWH are used where a small and infrequent usage is required such as small food service requirements, bakeries, hairdressing, etc. Temperatures are available from pre-tempered models at 50ᵒC up to 82ᵒC for sanitising applications. Naturally, a higher delivery temperature requires a higher temperature rise, and this inversely affects the flow rate capable of meeting the temperature rise.

Heavy duty electric is also suited to these applications. Being storage tanks with 32mm fittings they present no restriction to flow, however selection of appropriate kW and storage tank capacity is required to ensure peak demand is covered.

Tankpaks and Heat Pumps are combined with storage and are generally used in applications that have a large peak demand period such as apartments, hotels, etc.

The required inputs for sizing are to determine the peak demand (in litres), the period of the peak (in hours) and the temperature rise.

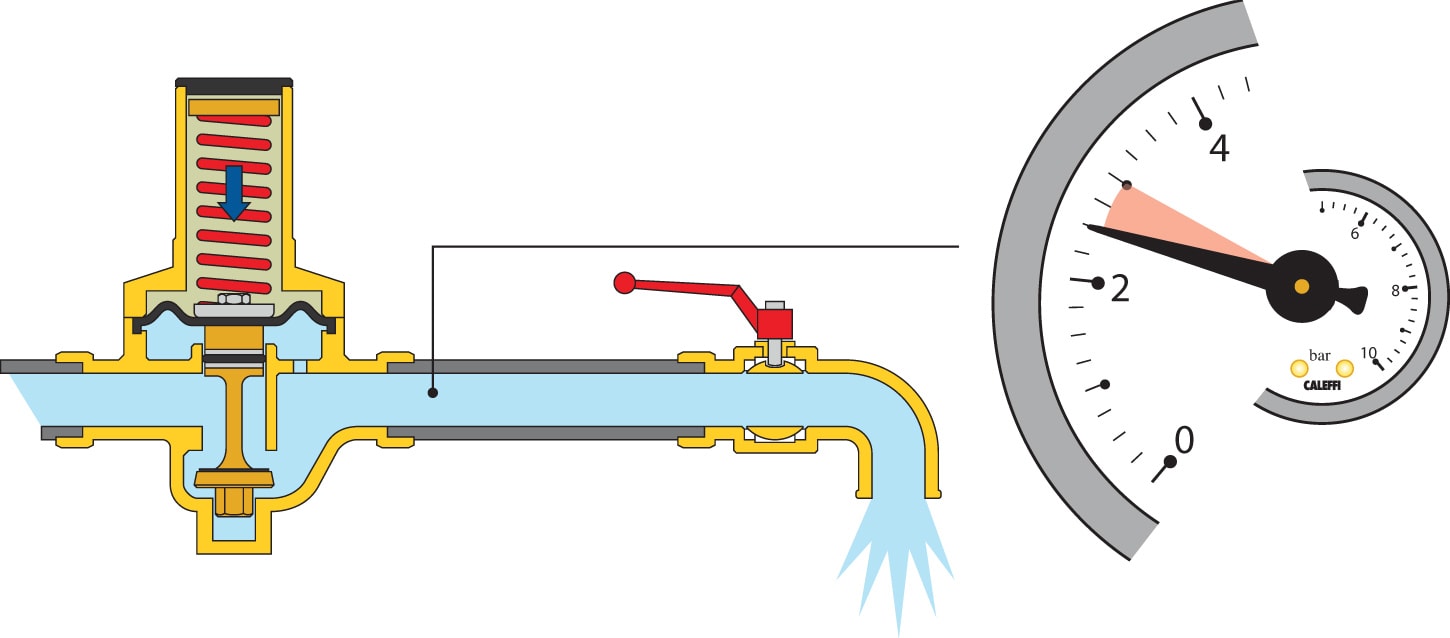

For Tankpaks, the plant is selected to meet the peak demand period based on recovery with a small amount of storage as a buffer to account for variations in probable simultaneous demand (PSD).

Conversely, Heat Pumps are a relatively slow recovery product and it is generally uneconomical to size the peak demand based on kW output. Instead, the plant is selected to meet the peak demand over the peak period using bulk storage, and allowing the Heat Pump plant to recover over a period of time, typically 4 to 5 hours.

Larger commercial applications will also have circulating ring mains (for more info on this refer to H2X blog post How to Design Hot Water Recirculation Systems), which impose a constant energy demand on the heating plant to maintain the temperature. This load, in kW per hour, is generally much smaller than the peak demand load and as Tankpak is sized to meet the peak demand using recovery will easily meet the ring main load, and any other subsequent usage, and further consideration is not required.

For heat pumps, the ring main heat loss load needs to be added to the peak demand recovery load to ensure the heat pump can maintain the temperature losses as well as recover in the designed time.

An alternative strategy is to use a hybrid system where traditional energy such as gas or electric water heaters are used to maintain the building heat loss load. The auxiliary heaters could be placed either in the return line or in the flow line in series with the heat pump storage. If in the latter, the plant is also useful as a ‘back-up’ to ensure a constant supply of hot water during the reheating period. In this case, the plant needs to be sized to meet the PSD requirements in terms of flow rate, as well as the ring main energy load.

Rheem TPS3 dlx 6 pak

The following example is used to illustrate how to size a Tankpak.

A building has a calculated daily load of 10,000 litres and a peak demand of 5,000 litres over 2 hrs at a 50 degree Celsius temperature rise.

For Tankpak sizing, only the peak demand load is required for sizing purposes.

The calculated peak load, in MJ, is given by the formula MJ = L x C x dT/1000

Where:

L = litres

C = specific heat of water 4.2kJ/L/ᵒC*

dT = temperature rise

1000 = conversion from kJ to MJ

Therefore, 5,000 x 4.2 x 50/1000 = 1,050MJ

Now, the peak is over 2 hours, therefore 1,050/2 = 525MJ/hr.

Each continuous flow gas water heater (CFGWH) has a thermal input of 205MJ/hr and a rated efficiency of 84%. The number of heaters required to meet this load is 525/(205 x 0.84) = 3.04

Therefore 3 x CFGWH will meet the load.

Select either indoor or outdoor model and either 1 x 340 or 1 x 430 tank as buffer storage to account for peak simultaneous demand which may exceed CFGWH capacity momentarily.

The lowest cost selection is TPS3E03NFD/1340.

Tankpak Series 3 is now also available with duty/standby primary pump option and/or duty standby secondary pump option factory assembled and wired onto the frame using new efficient Grundfos UPM series pumps (UPM3 is equivalent to UPS20-60N and UPMXL is equivalent to UPS32-80N).

Building heat loss now needs to be considered. At the time of design, the building heat loss load may not be known. As a rule of thumb, multiplying the daily load by .3 to .4 will produce a close approximation. Divide this by 24 to arrive at the hourly kW load.

The daily load is 2 x 1,050 = 2,100MJ. So, 2,100 x .4/24 = 35MJ/hr

Pump selection is based on flow rate vs pressure drop. We will discuss flow rate only here.

The required flow rate is selected to maintain the desired circuit temperature loss in degrees K for the given circuit heat loss.

The formula is a transposition of the formula used to determine the peak load:

E = L x 4.2 x dT/(1000 x 3600)

E =energy loss in MJ/hr

L = litres (as the energy is given in per hr units, the litres will also be per hr)

C = specific heat of water 4.2kJ/L/ᵒC*

dT = desired temperature loss (typically 5ᵒC)

1000 = conversion from kJ to MJ

3600 = conversion from L/hr to L/sec (dividing by 60 would produce L/min)

As we are looking for L/sec, transpose the formula as follows:

L = E x 1000 x 3600/(4.2 x dT)

Therefore, 35 x 1000 x 3600/(4.2 x 5) = 0.46L/sec or 27.6L/min.

The system pressure loss at this flow rate now needs to be determined to finalise the building return pump specification.

*(actual specific heat is 4.2kJ/kg/ᵒK, but simplified for illustration purposes as 1 L of water weighs 1kg and 1 o C is equal to 1ᵒK in non-absolute terms)

If you’ve made it this far, you have a keen interest in hot water sizing! Rheem are the experts,

contact us for your next sizing that may be somewhat unique, such as water-to-water heat pumps, on 132 552 or visit www.rheem.com.au

H2X’s design software will automatically size Rheem Hot Water plant based on your design layout.

If you would like to learn more or organise a free trial, book in for a chat with one of our experts.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP