Our Mission of Overcoming Plumbing Design Defects

Whilst this cost does not always get repaid by the engineer, the price is paid in a damaged relationship. Our mission is to reduce this percentage. We believe defects from the design phase should not be accepted as an industry standard.

Whilst this cost does not always get repaid by the engineer, the price is paid in a damaged relationship.

Our mission is to reduce this percentage. We believe defects from the design phase should not be accepted as an industry standard.

We aim to do reduce the percentage in many ways. One of the most important ways we reduce design errors is by alerting our users of them. We spoke to numerous designers, contractors, and manufacturers to find out what the common design errors were and then we built the warnings into our software.

Some examples of the design warnings built into H2X are:

Static Pressure at Fixtures

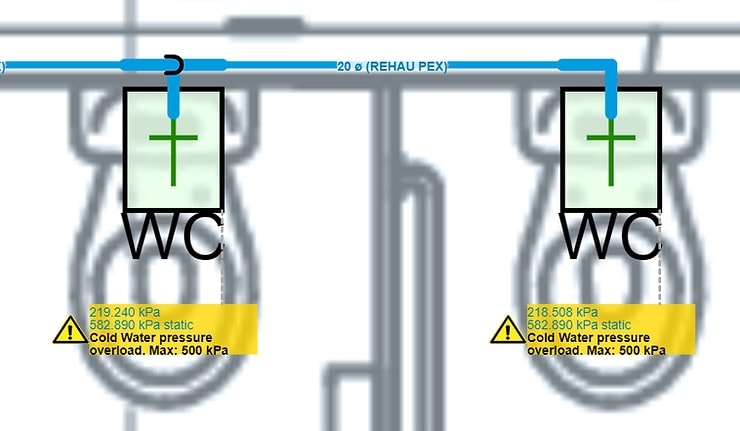

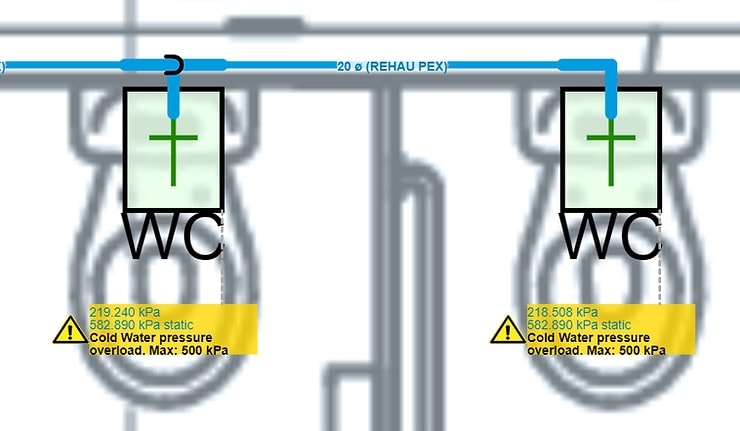

Calculating the peak pressure loss in a system is common, but what about caclulations when the pressure in the water main is high and there is minimal demand in the building?

In the scenario below, there is sufficient pressure during a peak demand, but there is >500 kPa during a non peak demand. A warning is produced to alert you that the maximum pressure in the system needs some attention.

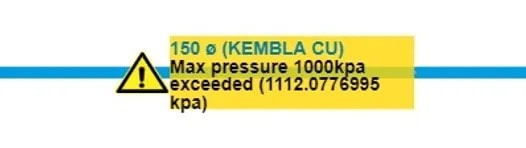

Safe Working Pressure Limitations of Pipes

In high-rise buildings, copper pipes are generally not a suitable choice because of their safe working pressure limitation.

In the scenario below, the 150mm copper pipe is subject to 1112 kPa which is above the safe working pressure of 1000 kPa. A warning is produced to alert you that the material needs to be changed.

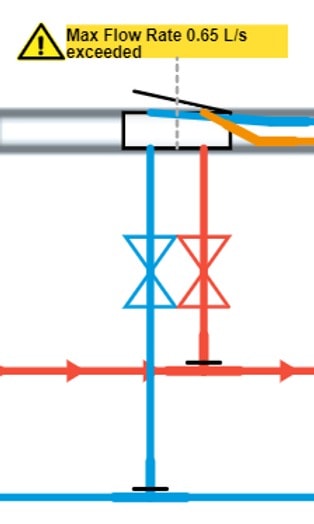

TMV Flow Rates

Whilst TMVs can serve multiple fixtures, they do have a maximum flow rate limit.

In the scenario below, the TMV is subject to a flow rate of 1.2 l/sec which is above the maximum flow rate limit. A warning is produced to alert you that modifying the TMV layout is required.

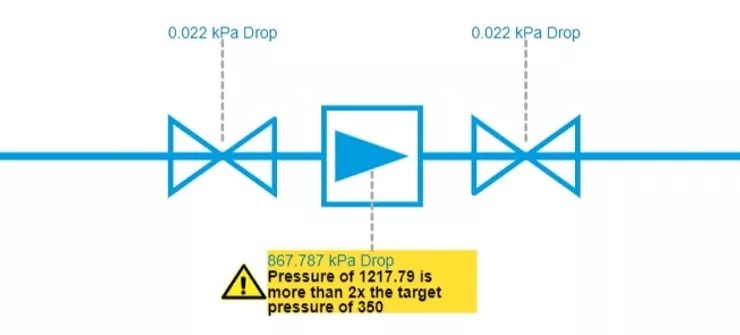

Pressure Reduction Valve Outlet Pressure

In tall buildings, pressure reduction valves will be required to ensure outlets are not subject to high pressure that will cause damage.

A common design scenario is needing to reduce from a pressure of 1200 kPa to a suitable outlet pressure of 350 kPa. Pressure reduction vavles are not recommended to reduce pressure at a ratio of more than 2:1 (e.g. 700 kPa to 350 kPa).

In the scenario below, the pressure reduction valve has an inlet pressure of 1217 kPa and an outlet pressure of 350 kPa. A warning is produced to alert you that the pressure reduction valve setting is too high and needs an alternate arrangement.

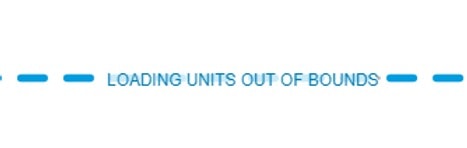

Exceeding the Limitations of the Standards

Standards have limitations. The most applicable example is the conversion from loading units/fixture flow rates to the probable simultaneous demand.

In the scenario below, the loading units in the project have exceeded the limitations in the Standards. This means the pipe is not able to be sized and is consequently displayed with a dashed line. You can change the probable simultaneous demand method to a suitable one and prepare a report to explain why you are unable to meet the Standards on the project.

Are there any design warnings that you would like to see us build into H2X? Let us know at info@h2xengineering.com

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP