Cooling Load Calculation:

The Essential Guide for Mechanical Engineers

In the realm of mechanical engineering, understanding cooling load calculations is paramount. Whether you're a seasoned engineer or just starting out, this article provides invaluable insights to enhance your expertise.

As the world gravitates towards energy efficiency, the significance of cooling load calculation in designing and implementing HVAC (Heating, Ventilation, and Air Conditioning) systems becomes paramount.

Let’s look deeper into this essential concept for mechanical engineers.

What is a Cooling Load?

The cooling load refers to the amount of heat energy that needs to be removed from a space to maintain a specified indoor temperature.

In simpler terms, it measures how hard an air conditioning system has to work to ensure a comfortable indoor environment.

What Impacts the Cooling Load?

Several factors can influence the cooling load:

- External Factors: These include the surrounding temperature difference, solar gain (heat from the sun penetrating the building), and relative humidity.

- Internal Factors: Inside the building, heat sources such as occupants, electronic devices, lighting, and machinery contribute.

- Building’s Construction: Materials used, insulation efficiency, type of windows, and building orientation can all alter the cooling load.

How Can You Reduce the Cooling Load?

Reducing the cooling load not only ensures energy efficiency, but also translates to cost savings.

Here’s how you can achieve it:

- Improve Insulation: Enhancing insulation reduces the heat transferred, thus decreasing the cooling load.

- Use Energy-efficient Windows: Double-glazed or tinted windows can prevent excessive solar gain.

- Strategic Landscaping: Planting trees or constructing shades to block direct sunlight can significantly reduce solar gain.

- Limit Internal Heat Sources: Opt for energy-efficient appliances and lighting to reduce the internal heat generated.

Why is Calculating the Cooling Load Important?

Determining the cooling load is crucial for:

- Energy Efficiency: An accurate cooling load calculation ensures the HVAC system operates with minimal energy wastage.

- System Sizing: It prevents the installation of undersized (leading to an insufficient cooling process) or oversized (leading to cost inefficiencies) HVAC systems.

- Occupant Comfort: Accurate calculations ensure that HVAC systems maintain a comfortable environment for occupants.

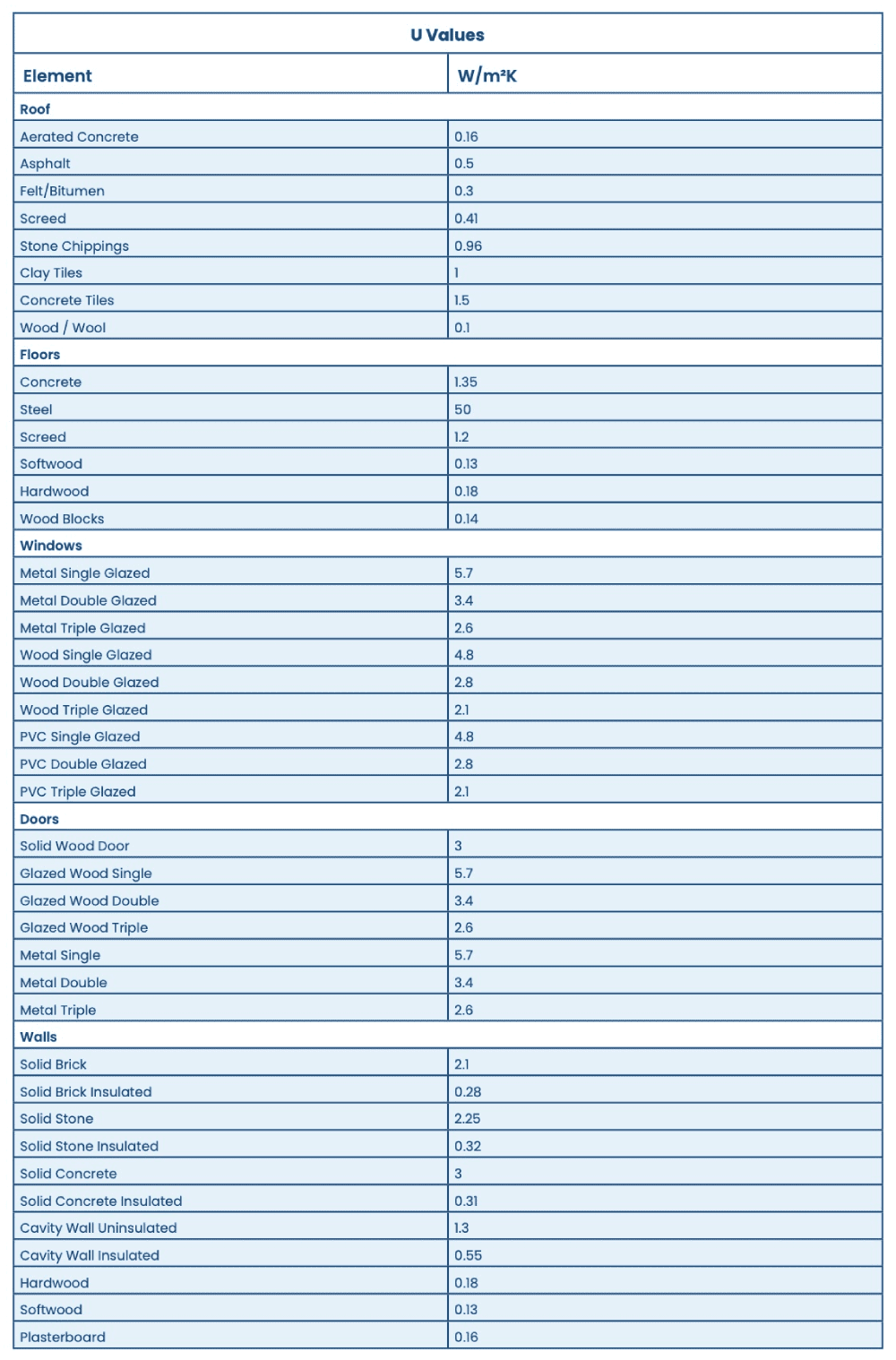

Common U-Values for Materials

Below, you can find some of the common U Values for various construction materials.

Doors:

- Glazed Wood Single: 5.7 W/m²K.

- Glazed Wood Double: 3.4 W/m²K.

- Glazed Wood Triple: 2.6 W/m²K.

- Metal Single: 5.7 W/m²K.

- Metal Double: 3.4 W/m²K.

- Metal Triple: 2.6 W/m²K.

- Solid Wood Door: 3 W/m²K.

Floors:

- Concrete: 1.35 W/m²K.

- Hardwood: 0.18 W/m²K.

- Screed: 1.2 W/m²K.

- Softwood: 0.13 W/m²K.

- Steel: 50 W/m²K.

- Wood Blocks: 0.14 W/m²K.

Roof:

- Aerated Concrete: 0.16 W/m²K.

- Asphalt: 0.5 W/m²K.

- Clay Tiles: 1 W/m²K.

- Concrete Tiles: 1.5 W/m²K.

- Felt/Bitumen: 0.3 W/m²K.

- Screed: 0.41 W/m²K.

- Stone Chippings: 0.96 W/m²K.

- Wood / Wool: 0.1 W/m²K.

Walls:

- Cavity Wall Insulated: 0.55 W/m²K.

- Cavity Wall Uninsulated: 1.3 W/m²K.

- Plasterboard: 0.16 W/m²K.

- Hardwood: 0.18 W/m²K.

- Softwood: 0.13 W/m²K.

- Solid Concrete: 3 W/m²K.

- Solid Concrete Insulated: 0.31 W/m²K.

- Solid Brick: 2.1 W/m²K.

- Solid Brick Insulated: 0.28 W/m²K.

- Solid Stone: 2.25 W/m²K.

- Solid Stone Insulated: 0.32 W/m²K.

Windows:

- Metal Single Glazed: 5.7 W/m²K.

- Metal Double Glazed: 3.4 W/m²K.

- Metal Triple Glazed: 2.6 W/m²K.

- PVC Single Glazed: 4.8 W/m²K.

- PVC Double Glazed: 2.8 W/m²K.

- PVC Triple Glazed: 2.1 W/m²K.

- Wood Single Glazed: 4.8 W/m²K.

- Wood Double Glazed: 2.8 W/m²K.

- Wood Triple Glazed: 2.1 W/m²K.

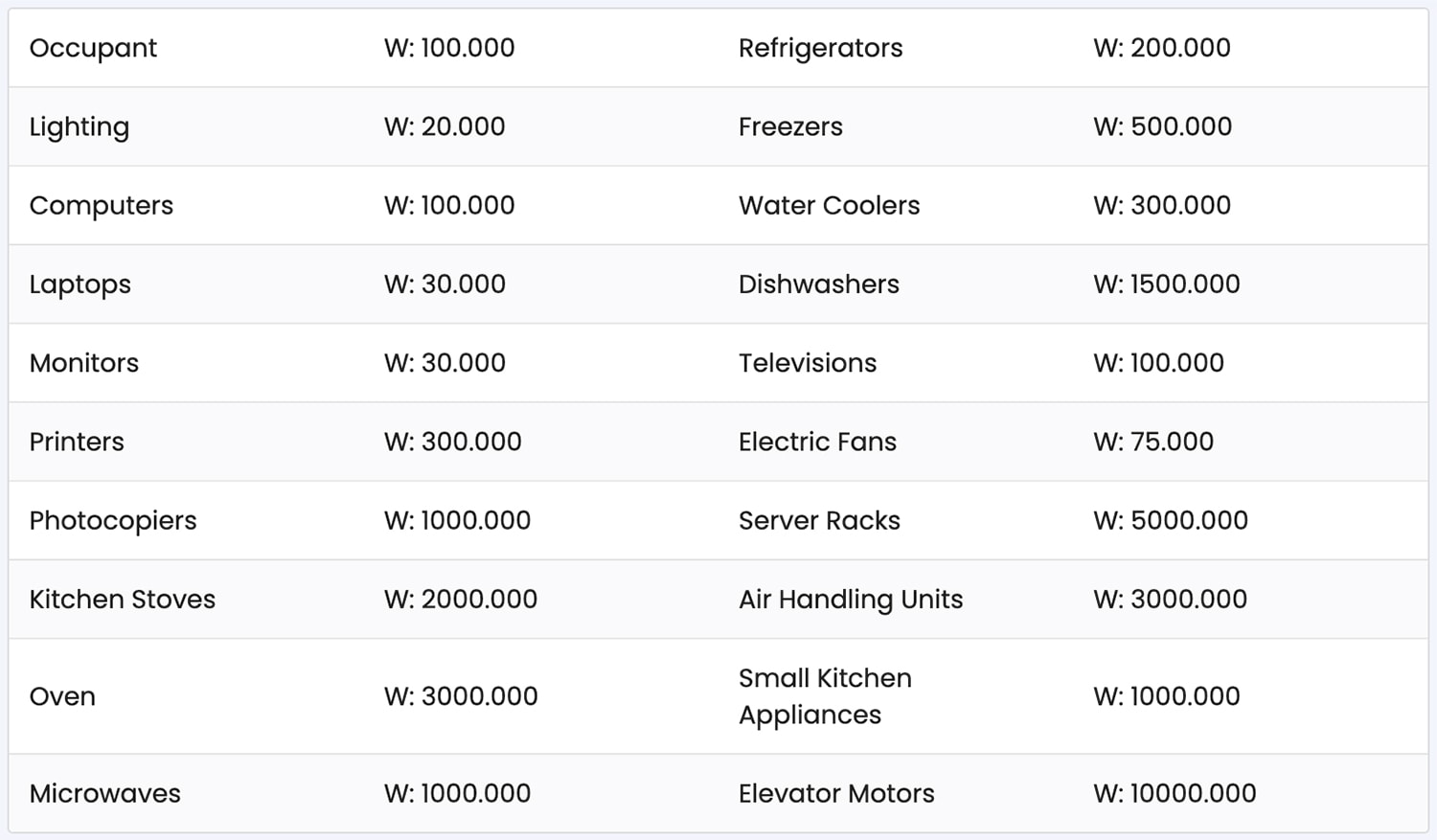

Typical internal heat source gains.

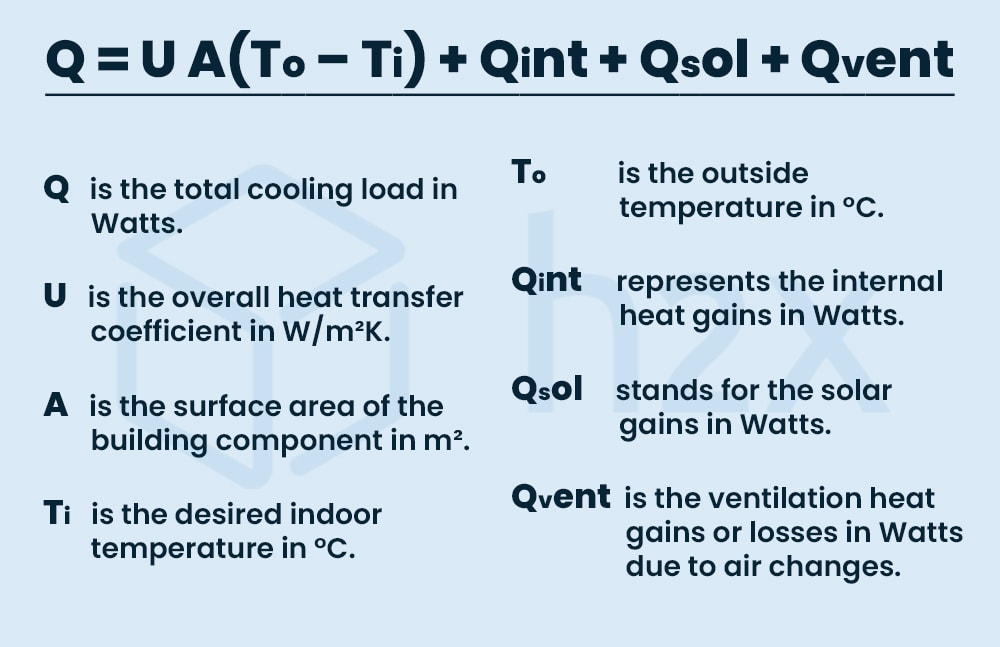

The Cooling Load Formula

While modern tools offer sophisticated calculations, the following formula is the basic one:

Q = U A(To – Ti) + Qint + Qsol + Qvent

Where:

Q is the total cooling load in Watts.

U is the overall heat transfer coefficient in W/m²K.

A is the surface area of the building component in m².

Ti is the desired indoor temperature in °C.

To is the outside temperature in °C.

Qint represents the internal heat gains in Watts.

Qsol stands for the solar gains in Watts.

Qvent indicates the ventilation heat gains or losses in Watts due to air changes.

The ventilation heat loss or gains (Qvent) can be further expressed as:

Qvent = ρ x Cp x V x (To – Ti)

Where:

ρ is the density of air, approximately 1.225 kg/m³ at sea level.

Cp is the specific heat capacity of air, approximately 1005 J/kg°C.

V is the volume of air exchanged per hour in m³/h.

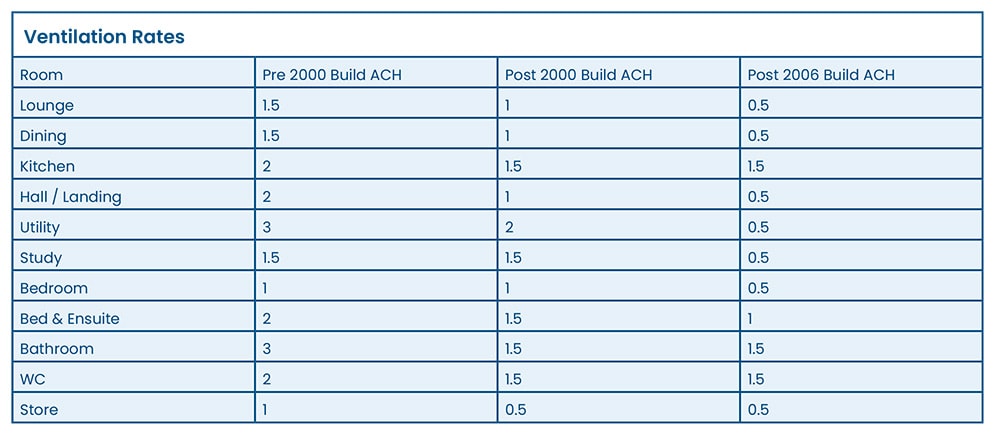

Typical air changes (ACH) per hour.

Cooling Load Calculation Example

Building Overview:

- A two-story building with four rooms.

- Elements include walls, roof, windows, and a door.

Building Dimensions and Materials:

1. Walls

- Surface Area: 200 m²

- Material: Brick with plaster

- Heat Transfer Coefficient (U): 1.5 W/m²K

- Calculation:

- Qwall = U * A * (To – Ti)

- Qwall = 1.5 W/m²K * 200 m² * (35°C – 24°C)

- Qwall = 3300 W

2. Roof

- Surface Area: 100 m²

- Material: Concrete slab with insulation

- Heat Transfer Coefficient (U): 0.7 W/m²K

- Calculation:

- Qroof = U * A * (To – Ti)

- Qroof = 0.7 W/m²K * 100 m² * (35°C – 24°C)

- Qroof = 770 W

3. Windows

- Surface Area: 20 m²

- Material: Double-glazed glass

- Heat Transfer Coefficient (U): 2.8 W/m²K

- Solar Transmission Coefficient (STC): 0.65

- Solar Radiation: 500 W/m²

- Calculation:

- Conduction:

- Qwindow_conduction = U * A * (To – Ti)

- Qwindow_conduction = 2.8 W/m²K * 20 m² * (35°C – 24°C)

- Qwindow_conduction = 616 W

- Solar Gain:

- Qwindow_solar = STC * Solar Radiation * A

- Qwindow_solar = 0.65 * 500 W/m² * 20 m²

- Qwindow_solar = 6500 W

- Total for Windows:

- Qwindow_total = Qwindow_conduction + Qwindow_solar

- Qwindow_total = 7116 W

4. Door

- Surface Area: 2 m²

- Material: Wood

- Heat Transfer Coefficient (U): 2.5 W/m²K

- Calculation:

- Qdoor = U * A * (To – Ti)

- Qdoor = 2.5 W/m²K * 2 m² * (35°C – 24°C)

- Qdoor = 55 W

5. Ventilation

- Air Change Rate: 0.7 changes per hour (volume = 500 m³, so 0.0972 m³/s)

- Calculation:

- Qvent = ρ * Cp * V * (To – Ti)

- Qvent = 1.225 kg/m³ * 1005 J/kg°C * 0.0972 m³/h * (35°C – 24°C)

- Qvent = 4877.5 W

6. Internal Heat Sources

- Occupants: 750 W

- Lighting: 300 W

- Electronic Equipment: 2300 W

- Other Appliances: 200 W

- Total for Internal Sources:

- Qinternal = Qoccupants + Qlighting + Qelectronics + Qappliances

- Qinternal = 3550 W

Combining All Elements:

Qtotal = Qwall + Qroof + Qwindow_total + Qdoor + Qvent + Qinternal

Qtotal = 3300 W + 770 W + 7116 W + 55 W + 4877.5 W + 3550 W

Qtotal = 19668.5 W

To maintain the desired indoor temperature, the HVAC (Heating, Ventilation, and Air Conditioning) system needs to counteract a total heat gain of 19,668.5 Watts.

Conclusion

The cooling load calculation is a cornerstone for mechanical engineers in designing HVAC systems that are both energy-efficient and effective in providing optimal comfort.

The impact of the digital revolution on various industries is a tale recounted repeatedly, and chilled water system design is no different in this narrative.

With the right tools, like h2x Engineering’s Cooling Load Calculation Software, you can drive precision and efficiency in your cooling systems projects.

Adopting digital advancements in cooling and heating design software, such as the solutions provided by h2x, is essential for professionals aiming to maintain competitiveness within the industry.

It provides a combination of convenience, accuracy, and effectiveness that traditional approaches cannot rival.

Give your cooling system designs the h2x advantage and experience the difference by booking a demo or by starting your free trial today!

Frequently Asked Questions

Q: Can I estimate the average cooling load without professional tools?

A: While the basic formula gives an estimate, professional tools offer more accurate results, considering a broader range of variables.

Q: How often should I recalculate the cooling loads for a building?

A: Anytime there are significant changes, such as renovations, changes in building use, or major appliance additions, it’s wise to calculate the cooling load again.

Q: What role do U-Values of materials play in cooling load calculations?

A: The U Values of materials are essential in assessing the transmission load in a building.

They help calculate how quickly thermal energy moves through building materials, which impacts the overall cooling required to maintain thermal comfort.

By understanding the U Values, engineers can account for heat added or removed through walls, windows and roofs, among other factors.

Q: How can I calculate the total cooling load for a space?

A: Calculating the total cooling load for a space involves evaluating various factors, such as internal heat load, air infiltration, ventilation fans, and more.

In most cases, it starts with assessing the internal temperature and volume changes.

The next thing to consider is the temperature change and any other factors contributing to the heat load.

By adding up all the energy sources and accounting for a safety factor, engineers can calculate the total cooling load in a fairly simple way to determine the appropriate air conditioning unit or cooling coil required for a space.

Q: Is solar gain always bad?

A: Not necessarily.

In colder climates, solar gain can help reduce heating loads.

The key is to balance it according to the specific needs of the building.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP