A Guide To Air Duct Pressure Drop Calculation For Optimal HVAC Performance

Discover the science behind efficient HVAC systems! Explore h2x Engineering's insightful blog on Air Duct Pressure Drop Calculation for optimal airflow design.

An Introduction To Air Duct Pressure Drop Calculation

An Air duct pressure drop calculation is essential for designing and operating HVAC (Heating, Ventilation, and Air Conditioning) systems.

Understanding how to calculate pressure drops in air ducts allows mechanical engineers to design more efficient and effective systems, ensuring optimal airflow and comfort in residential and commercial spaces.

Why Air Duct Pressure Drop Calculation Is Important

Accurate air duct pressure drop calculations are a vital aspect of HVAC system design, because they assess potential pressure losses as air flows through ductwork.

It involves factors like fluid flow, velocity, and atmospheric pressure. Some more reasons as to why air duct pressure drop calculations are important:

- They help size the ducts appropriately, ensuring the system can handle the required airflow without excessive energy consumption.

- They are crucial in selecting the right fans and other components, as underestimating pressure drops can lead to undersized equipment that may not perform adequately.

- Proper calculations contribute to the overall energy efficiency of the building, reducing operational costs and environmental impact.

What Could Go Wrong If Not Done Correctly

Incorrect calculations can lead to multiple issues.

Overestimating pressure drops may result in oversized and costlier components, increased energy consumption, and unnecessary noise.

On the other hand, underestimation can cause inadequate airflow, leading to discomfort, poor air quality, and even system failure due to overloading of components.

Thus, precision in these calculations is paramount.

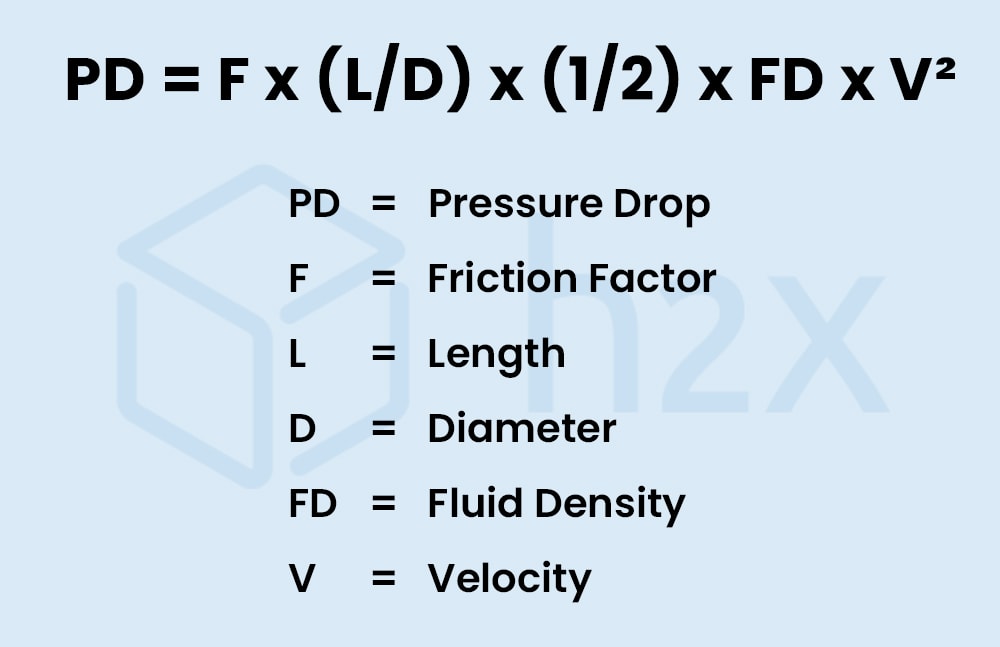

The Air Duct Pressure Drop Calculation Formula

Pressure Drop = Friction Factor * (Length/Diameter) * (1/2) * Fluid Density * Velocity²

Next, we need to check if that size will exceed the maximum pressure drop per metre.

Hypothetical Example

1. Calculate the Velocity

We need to calculate the Velocity for a 100mm (4″) duct, which we propose to use for the pressure drop calculation.

Velocity formula:

V = Q / A

Area formula:

A = 3.14 * (d/2)²

A = 3.14 * (0.05)²

A = 0.00785 m²

Therefore, the Velocity is:

V = 0.029 m³/s / 0.00785 m²

V = 3.69 m/s

2. Calculate the Reynolds Number

To inform the pressure drop, we also need to calculate the Reynolds number (Re), which uses the following formula:

Re = Velocity * Diameter * Density / Viscosity

Re = (3.69 m/s * 0.1m * 1.2 kg/m³) / 1.8e-5 Pa.s

Re = 24,600

3. Calculate the Friction Factor

We also need to calculate the Friction Factor (f) to inform the pressure drop.

f = (0.11×((Roughness Coefficient/Diameter) + (68/Re))^0.25) * 0.85 + 0.0028

f = (0.11×((0.5/100) + (68/24600))^0.25) * 0.85 + 0.0028

f = (0.11×(0.005 + 0.00276)^0.25) * 0.85 + 0.0028

f = 0.03055

4. Calculate the Pressure Drop

The final step, is to check whether we lose more than 1 Pa/m.

The formula is:

Pressure Drop = f * (Length/Diameter) * (1/2) * Fluid Density * Velocity²

Pressure Drop = 0.03055 * 10 * 0.5 * 1.2 * 3.69²

Pressure Drop = 2.5 Pa/m

Our maximum pressure drop per metre, for an efficient system, is 1 Pa/m.

Even though a 100mm (4″) duct can supply the flow rate at a velocity below 4 m/s, there will be too much pressure drop.

Therefore, we will need to increase to the next duct size and redo the calculation.

By following the same process, a 150mm (6″) diameter duct has a pressure drop of 0.33 Pa/m.

Our duct size needs to be 150mm (6″).

Conclusion

Understanding and accurately calculating the pressure drop in air ducts is crucial for designing and operating efficient HVAC systems.

Mechanical engineers must use precise calculations to ensure that the systems they design are cost-effective, energy-efficient, and capable of providing the desired comfort levels.

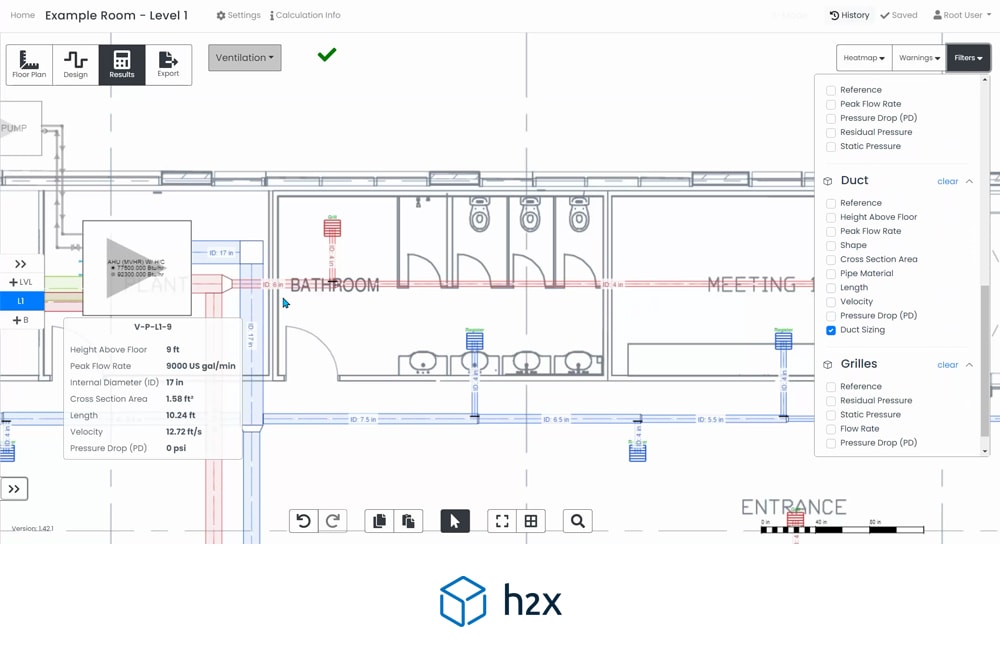

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The tool streamlines flow rate, velocity, pressure, pump duty, plant size, and recirculation system calculations, liberating you from laborious math tasks and allowing you to focus on the design of your project.

With its straightforward user interface, h2x assists engineers in producing high-quality designs and working more efficiently, all the while adhering to industry regulations.

The software has sized millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

FAQs

Q: Can the same formula be used for all types of ducts?

A: While the basic formula is widely applicable, adjustments may be needed based on the duct shape, surface roughness, and air temperature and humidity.

Q: How can I determine the friction (f) factor?

A: The friction (f) factor can be determined using the Colebrook-White equation or derived from the Moody chart, depending on the Reynolds number and the relative roughness of the duct.

Q: What is the significance of the Reynolds number in these calculations?

A: The Reynolds number helps determine the flow regime (laminar or turbulent), directly affecting the friction (f) factor and, consequently, the pressure drop.

Q: How do environmental factors like temperature and altitude affect these calculations?

A: Changes in air density due to temperature and altitude variations can significantly affect pressure drop calculations.

Engineers must consider local conditions for accurate results, incorporating Bernoulli’s equation to understand the dynamic relationship between air flow and environmental factors.

More information on the Bernoulli equation can be ready here.

Q: What is considered a good pressure drop per meter in air ducts?

A: Generally, a good pressure drop per meter is one that balances efficiency and cost-effectiveness.

A pressure drop between 0.5 to 2 Pa/m is acceptable for most commercial systems.

However, the ideal value can vary depending on the specific system design and requirements.

Q: Why is it important to maintain a recommended pressure drop?

A: Maintaining a recommended pressure drop ensures that the HVAC system operates efficiently, providing adequate airflow without overburdening the fans or increasing energy consumption.

It also helps prolong the system components’ lifespan by preventing excessive wear and tear.

Q: Can the recommended pressure drop per meter vary between different types of buildings?

A: The recommended pressure drop can vary based on the building type and specific requirements.

For instance, industrial facilities might tolerate higher a pressure drop due to their robust systems, while residential buildings typically require a lower pressure drop for comfort and efficiency.

Q: How does duct size affect the recommended pressure drop?

A: Larger ducts generally have lower pressure drops per meter because they allow air to flow more easily.

Conversely, smaller ducts increase resistance to airflow, leading to a higher pressure drop.

Thus, duct sizing is critical in maintaining an optimal pressure drop.

Q: How does air velocity determine the pressure drop per meter?

A: Higher air velocities typically result in higher pressure drops due to increased friction and dynamic pressure.

Engineers must balance air velocity and duct size to achieve a recommended pressure drop that ensures efficient operation.

Q: What should I do if the measured pressure drop per meter is significantly higher than recommended?

A: If the pressure drop is higher than recommended, it could indicate issues like duct leakage, blockages, or incorrect sizing.

You should inspect the ductwork for any obstructions or damages and consult with a professional to assess and rectify the issue.

Q: How do different materials affect the recommended pressure drop per meter?

A: The material of the duct can affect the surface roughness and, consequently, the friction (f) factor.

Materials with smoother surfaces generally result in a lower pressure drop.

Common duct materials include galvanised steel, aluminium, and flexible ducting, each with different impacts on pressure drop.

Q: What are the key components affecting pressure loss in a ductwork system?

A: Various elements, including a round duct, straight ducts, duct fittings, and kinetic energy, play a role in determining total pressure in a ductwork system.

Q: How does turbulent flow impact air duct pressure drop?

A: Turbulent flow, a key consideration in air duct pressure drop calculations, influences flow velocity and can contribute to the total pressure loss within duct systems.

Q: Can you explain the Velocity Reduction Method in air duct pressure drop calculation?

A: The Velocity Reduction Method is a technique used to determine pressure loss as air passes through duct fittings, considering factors like duct cross sectional area and average velocity.

Q: How is the Darcy Weisbach equation used in air duct pressure drop calculation?

A: The Darcy-Weisbach equation, a fundamental formula, helps calculate friction loss in ducts by considering parameters like dynamic viscosity, hydraulic diameter, and duct cross section area.

Q: In what cases does the C coefficient become crucial in air duct pressure drop calculations?

A: The C coefficient, significant in assessing friction losses, becomes crucial when determining the total pressure loss in ducts of varying types and configurations.

Q: How is potential energy factored into air duct pressure drop calculations?

A: Potential energy considerations in air duct pressure drop calculations involve understanding pressure changes as air flows through duct systems.

Q: What role does the incompressible nature of fluids play in determining pressure losses in ducts?

A: The nature of incompressible fluids is a key factor, affecting how pressure losses are evaluated in various duct types to ensure accurate calculations.

Q: What factors influence air flow in HVAC systems?

A: Air flow is a crucial aspect of HVAC system performance.

Various factors, including duct design, filters, and equipment sizing, influence air flow dynamics.

Q: What is the equal friction method in air duct design?

A: The equal friction method is a systematic approach employed in air duct design to maintain a consistent friction (f) factor throughout the entire duct system.

This method ensures that the pressure drop per unit length remains uniform, promoting balanced air flow and optimising HVAC system performance.

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP