Fixed Speed vs. Variable Speed Pumps

Uncover the pros and cons of fixed vs. variable speed pumps in h2x Engineering's informative blog post. Choose the right pump for your needs today!

Uncover the pros and cons of fixed vs. variable speed pumps in our informative blog post. Choose the right pump for your needs today!

Introduction to Fixed vs. Variable Speed Pumps:

Navigating the pump selection process can be compared to adjusting the light in a room.

A fixed-speed pump is like a light bulb controlled by a simple on/off switch, providing full brightness or no light at all.

In contrast, a variable speed pump is more like a dimmer switch, allowing you to adjust the brightness to just the right level.

Let’s examime these two types of pumps and illuminate their various features and use cases to guide your pump selection journey.

Fixed Speed Pumps:

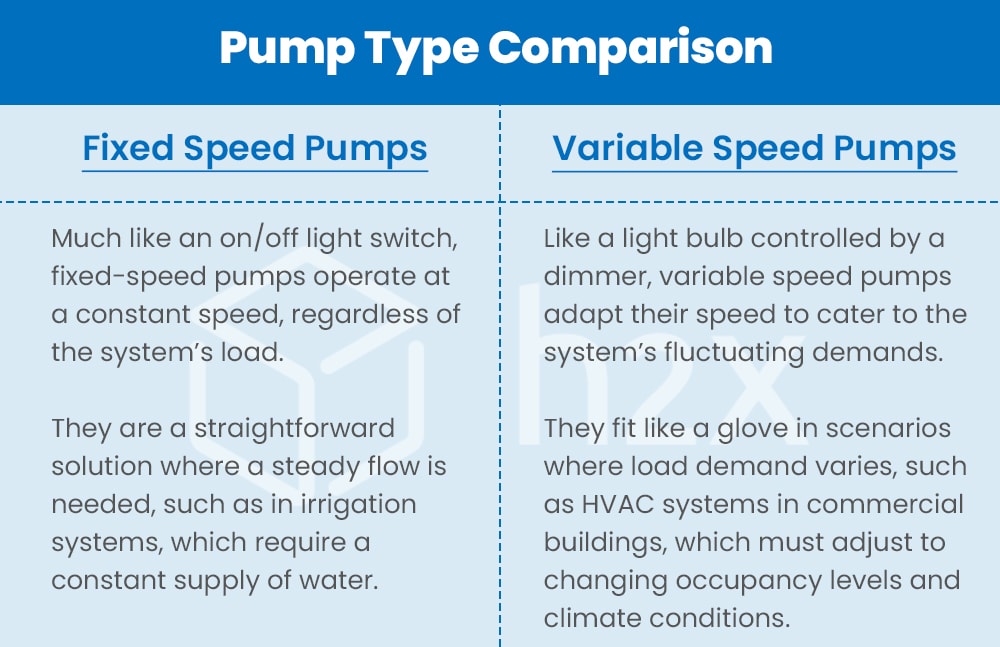

Much like an on/off light switch, fixed-speed pumps operate at a constant speed, regardless of the system’s load.

They are a straightforward solution where a steady flow is needed, such as in irrigation systems, which require a constant supply of water.

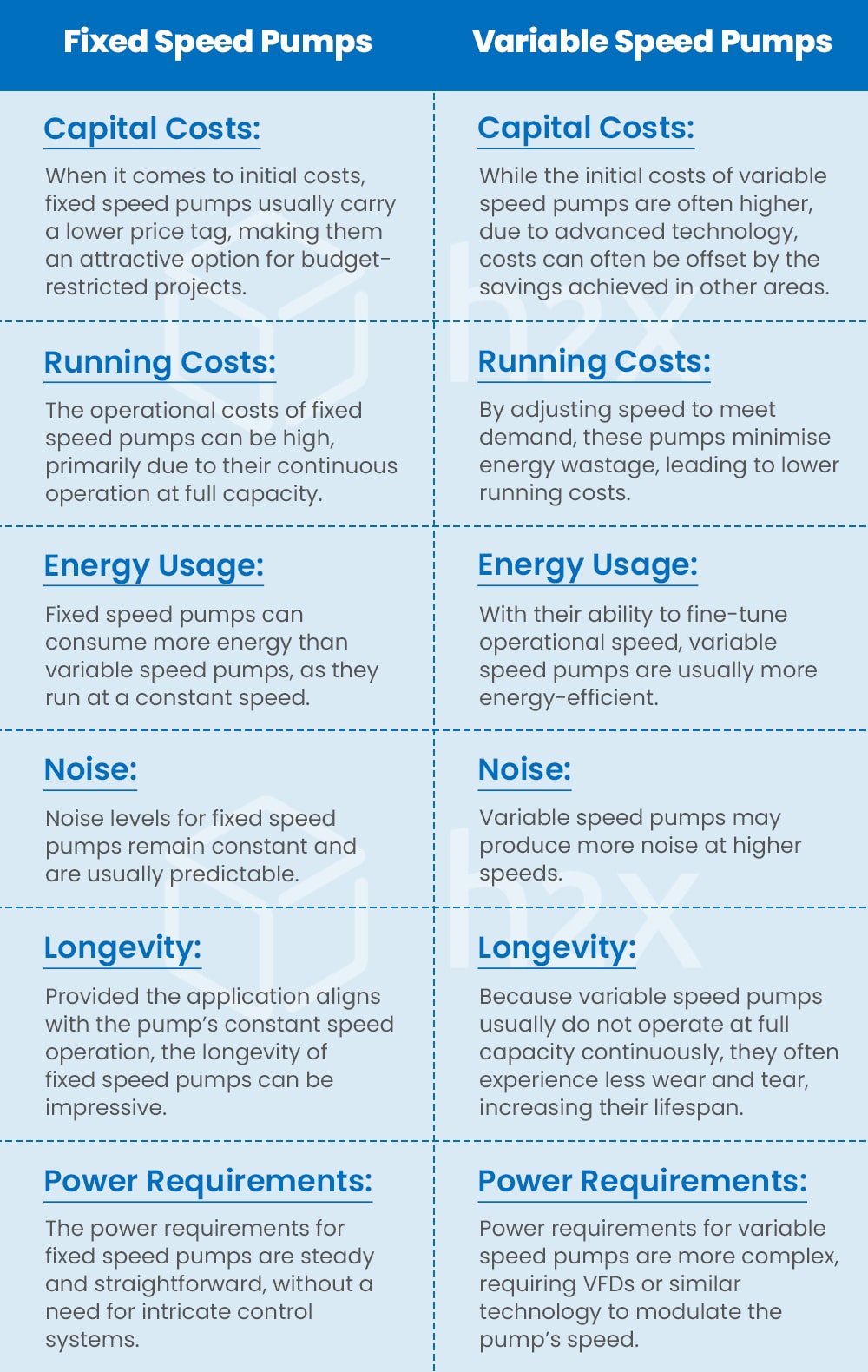

Capital Costs

When it comes to initial costs, fixed-speed pumps usually carry a lower price tag, making them an attractive option for budget-restricted projects.

Running Costs

On the flip side, the operational costs of fixed-speed pumps can be high, primarily due to their continuous operation at full capacity, even during lower demand periods.

Energy Usage

Regarding energy usage, fixed-speed pumps can consume more energy than variable-speed pumps, as they run at a constant speed regardless of the system’s demand.

Noise

Noise levels for fixed-speed pumps remain constant and are usually predictable, as they are directly related to the pump’s operational speed.

Longevity

Provided the application aligns with the pump’s constant speed operation, the longevity of fixed-speed pumps can be impressive.

Power Requirements

The power requirements for fixed-speed pumps are steady and straightforward, without a need for intricate control systems to adjust the pump’s speed.

Variable Speed Pumps:

Like a light bulb controlled by a dimmer, variable speed pumps adapt their speed to cater to the system’s fluctuating demands.

They fit like a glove in scenarios where load demand varies, such as HVAC systems in commercial buildings, which must adjust to changing occupancy levels and climate conditions.

Capital Costs

While the initial costs of variable speed pumps are typically higher than those of fixed speed pumps, due to their advanced technology like Variable Frequency Drives (VFDs), these costs can often be offset by the savings achieved in other areas.

Running Costs

The real savings of variable speed pumps come into play when considering operational costs. By adjusting speed to meet demand, these pumps minimise energy wastage, leading to lower running costs.

Energy Usage

With their ability to fine-tune operational speed, variable speed pumps are usually more energy-efficient.

Noise

Variable-speed pumps may produce more noise at higher speeds. However, modern VFDs and proper installation practices can manage noise effectively.

Longevity

Because variable speed pumps usually do not operate at full capacity continuously, they often experience less wear and tear, potentially increasing their lifespan.

Power Requirements

Power requirements for variable-speed pumps are more complex, requiring VFDs or similar technology to modulate the pump’s speed.

Conclusion:

Choosing between fixed and variable speed pumps is like deciding between an on/off switch and a dimmer for your lighting.

For systems with constant loads, the simplicity and lower upfront costs of a fixed-speed pump might prove optimal.

Conversely, in varying load scenarios, a variable speed pump’s energy efficiency and potential cost savings can justify the higher initial investment.

As always, understanding the specific needs of your project is paramount.

If you want to learn more about about pumps, check out these other blog articles on Recircluation Pumps and Booster Pumps!

FAQs:

Can a fixed-speed pump be converted into a variable-speed pump?

Yes, with the addition of a variable frequency drive (VFD), a fixed-speed pump can be converted into a variable-speed pump.

However, depending on the specific application and pump design, this may not always be cost-effective or practical.

Do variable-speed pumps last longer than fixed-speed pumps?

Generally, variable-speed pumps can last longer because they are less likely to run at full capacity all the time, reducing wear and tear on pump components. However, their lifespan also depends on the quality of installation, maintenance, and the specifics of the application.

Are variable-speed pumps noisier than fixed-speed pumps?

Variable-speed pumps may produce more noise at higher speeds. However, noise can be effectively managed with modern VFDs and proper installation practices. Fixed-speed pumps, on the other hand, have a constant noise level.

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The software provides automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems, allowing you to focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP