HTC Group – Mains Flow and Pressure Testing, Australia

Accurate town main supply pressure ensures the hydraulic consultants’ hydrant design incorporates pumps and/or tanks early in the design phase and minimises the risk of failing the commissioning test.

Hydraulic consultants go to great lengths to calculate the pressure loss of their hydrant systems to size the pipes and ensure there are no unnecessary pumps and/or tanks. The biggest factor in determining if the design is compliant and efficient, after the calculated pressure loss, is the input mains supply pressure. The hydrant design is only as strong as these two pressures combined.

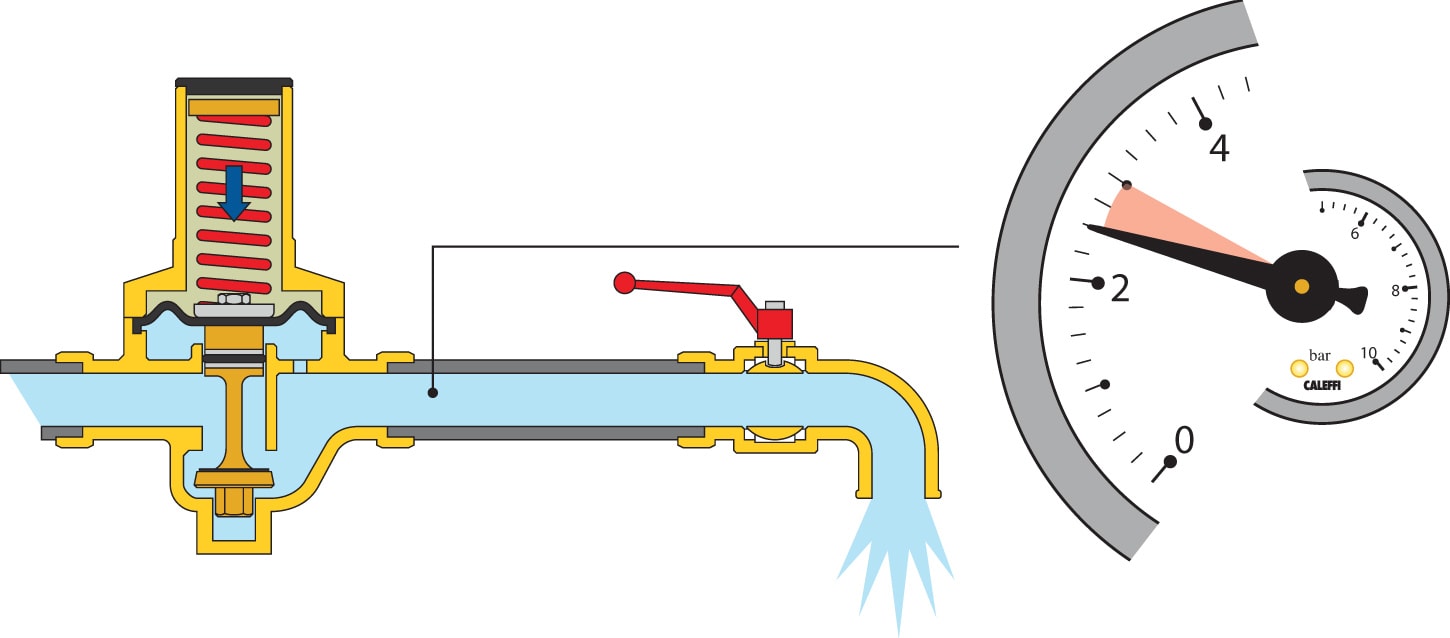

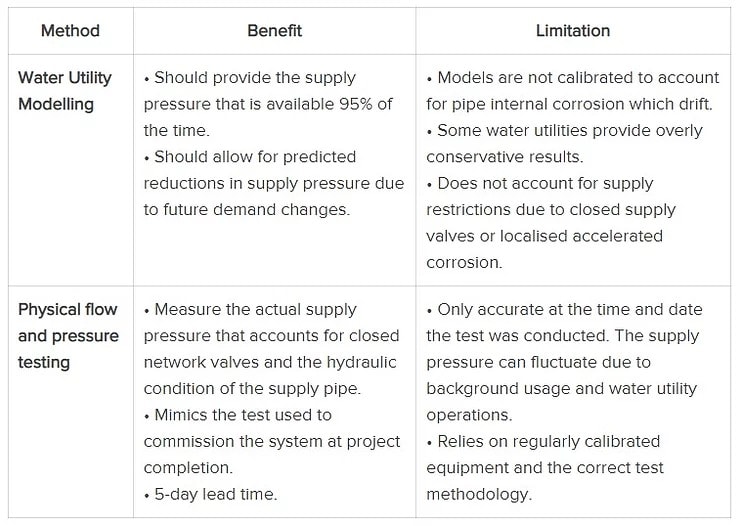

There are two ways to determine the mains supply pressure. The first is to use water utility model data, and the second is to physically measure the available flow and pressure. Each method has benefits and limitations which are summarised below. Hydraulic consultants may choose to obtain both water utility modelling and physical flow and pressure testing to take advantage of the benefits of both methods.

Physical flow and pressure testing ensures that the hydraulic consultants’ design efforts are not weakened by overly, or underly, conservative mains supply pressures. At HTC Group our aim is the same as yours, to ensure each hydrant design avoids pumps and tanks if possible, and to ensure the hydrant system passes the commissioning test with no surprises.

Questions? Contact Dan Barwick from HTC Group at Dan@HydrantTesting.com.au

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP