Does Your Pipe Design Cause Legionella? By REHAU

Legionnaires’ disease is a type of pneumonia caused by Legionella bacteria, which naturally exists in freshwater environments like lakes and streams.

However, it becomes a health concern when it grows and spreads in human-made water systems like plumbing systems.

In this article, we’ll dive deep into understanding this disease and how it’s closely tied to our everyday water systems.

Who is at risk from Legionella?

People with weakened immune systems are at a higher risk of Legionnaires’ disease, as they may not be able to fight off the infection as effectively.

This is why hospitals and other healthcare facilities are high-risk environments.

Moreover, the complex water systems in hospitals can harbour Legionella bacteria if not properly managed and maintained.

Legionella’s preferred environment

Legionella bacteria are highly adaptive organisms that can survive in a variety of environmental conditions.

However, they have a particular affinity for certain conditions that allow them to thrive, and unfortunately, human-made water systems can sometimes provide the ideal breeding ground.

This includes:

Temperature:

- Legionella bacteria love warm temperatures. They are most comfortable in water temperatures between 20°C to 50°C (68°F to 122°F).

- In this temperature range, they grow rapidly and reproduce.

- They can survive in lower temperatures and can even withstand freezing, but they become dormant and don’t multiply.

- On the other hand, temperatures above 50°C (122°F) are less hospitable for these bacteria, and they start to die off.

- Above 60°C (140°F), the bacteria cannot survive and are killed fairly quickly.

Stagnant Water:

- Legionella bacteria are more likely to proliferate in stagnant water.

- This is because stagnant water allows the bacteria to form a biofilm – a protective layer of bacteria and other microorganisms.

- Biofilms not only shield the bacteria from heat and disinfectants but also provide nutrients for the bacteria.

- Therefore, areas of a plumbing system where water is often stationary or slow-moving can become hotspots for Legionella growth.

Nutrient-Rich Environments:

- These bacteria thrive in environments that are rich in iron and organic matter.

- This is often found in scale, a buildup of minerals inside pipes, and in the biofilms mentioned earlier.

- Certain plumbing materials can also encourage biofilm development, thereby providing a conducive environment for Legionella.

Aerosolisation:

- Legionella bacteria need to be aerosolised to cause infection, which means they must be suspended in the air in small droplets of water (aerosols) that can be inhaled.

- Showers, faucets, hot tubs, cooling towers, and fountains can all generate aerosols and hence are potential sources of infection if they are contaminated with Legionella.

- In summary, the bacteria that cause Legionnaires’ disease are particularly fond of warm, stagnant water rich in nutrients – conditions often found in improperly designed and maintained water systems.

- Understanding what conditions Legionella bacteria like can help us to design systems that prevent their growth and reduce the risk of Legionnaires’ disease.

Legionella control with smarter plumbing systems

Legionnaires’ disease is a difficult challenge in buildings throughout the world.

Therefore, careful consideration should be given to the design, smarter operation, and maintenance of water distribution systems.

Some common strategies implemented to minimise the risk of Legionella are:

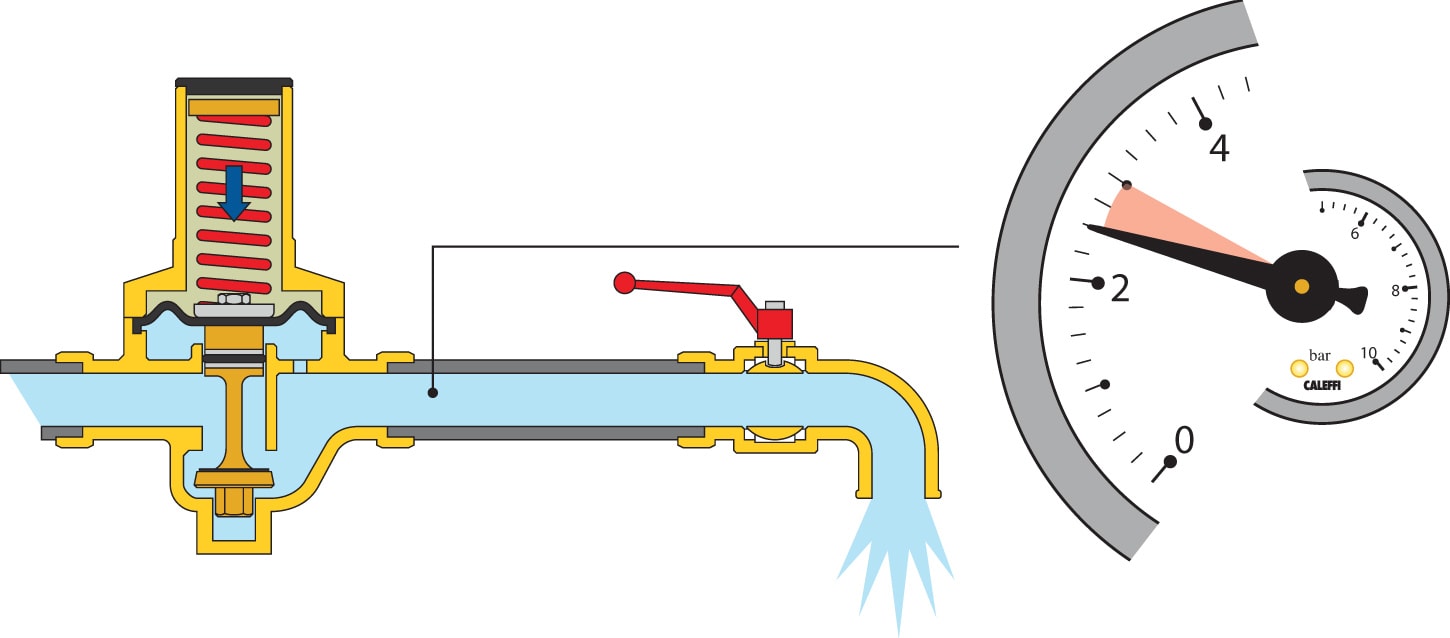

Temperature:

- Avoid locating cold water pipes in places where they could be exposed to heat during summer e.g. outside or in attic spaces.

- Ensure all hot water systems are heated to above 60°C (140°F) to kill the bacteria.

Stagnant Water:

- Minimise the number of areas in your design where stagnant water can occur.

- Add flushing points to the system to ensure the system can be flushed at a self-cleansing velocity (~0.8m/s+).

- Monitor the system to be made aware of areas where the water system hasn’t been used e.g. vacant bedrooms in hospitals.

Nutrient-Rich Environments:

- Add filters to the incoming water supply to remove organic matter and prevent bacteria from being able to thrive in the environment.

Aerosolisation:

- Minimise the areas where the force of the water hitting a surface will cause aerosols.

In the remainder of this blog, we will focus on design tips relating to pipework supplying fixtures.

Design principles to limit stagnant water

One of the main factors in minimising the risk of Legionella bacteria is the correct design of the pipes that connect to the fixtures. These are commonly referred to as dead-legs and idle-legs.

Avoiding or reducing dead-legs and idle-legs is imperative. They can be described as:

Idle-legs:

- Sections of pipe connected to fixtures that are used infrequently, i.e. water in the pipe not flushed for more than 7 days.

Dead-legs:

- Sections in pipe that do not allow water to circulate, i.e. sections of pipe that are capped.

These are the high-level parameters you should design to:

Minimise pipe runs:

- The longer the pipe run, the more volume of water there is for Legionella to thrive.

Minimise pipe sizes:

- The larger the pipe size, the more volume of water there is for Legionella to thrive.

Promote the movement of water:

- The less frequently the water moves, the higher likelihood there is for legionella to thrive.

This video explains some key concepts:

How REHAU helps to minimise Legionella

As a leading innovator in advanced plumbing systems globally, REHAU has developed a range of fittings and design methodologies which target Plumbing Controls and Regular Maintenance Controls.

With REHAU’s RAUTITAN Lead-Free anti-stagnation fittings, water flow can be supported to eliminate idle-legs and therefore minimise the risks of Legionella.

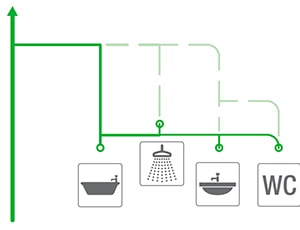

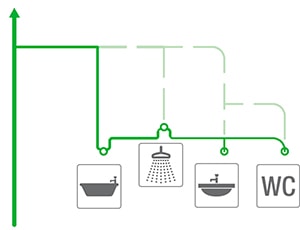

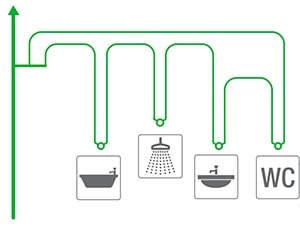

T-piece installation – Typical “standard” type installation using T-piece fittings. To improve water hygiene, branch lines should in general be reduced to a minimum. Idle-legs cannot always be prevented with this design but the risk can be reduced if the fixture is used regularly.

Series installation – Using REHAU’s U-bend fitting connected directly to lower-use fixtures, a complete water flush is ensured when opening the last fixture in the water line. This last fixture should be the one that is more frequently used. Automatic taps can also be used when regular use of that one fixture is not guaranteed.

Ring installation – With this type of installation, all fixtures are connected with an anti-stagnation fitting (U-bend or threaded T-piece) via a ring line. Since the water flows to each fixture from two sides, pressure losses are minimised and the water in the entire line is set in motion via the use of any single fixture.

Watch the Minimising-Legionella design principles with REHAU fittings video for a visual explanation of the fittings, their functions and how they can be best used against Legionella.

By employing the design principles and fittings selected as stated above, a smarter plumbing system can be created which can reduce the ongoing system maintenance that is currently required to control the risks of Legionella.

h2x is design software built to ensure compliance, efficiency, accuracy and collaboration.

The software provides automated calculations for flow rates, velocities, pressures, pump duties, plant sizing, and recirculation systems, allowing you to focus on your project’s design instead of undertaking tedious calculations.

h2x’s straightforward user interface helps engineers produce high-quality designs and work more efficiently, all while adhering to industry regulations.

The software has already been used to size millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP