Prefabricate Your Design & Calculation Process

'Prefabrication' is a word that has positive connotations, and rightly so. The word associates with quality, efficiency, innovation, and organisation. Prefabrication within the construction industry naturally makes you think of the construction phase of a project

‘Prefabrication’ is a word that has positive connotations, and rightly so. The word associates with quality, efficiency, innovation, and organisation.

Prefabrication within the construction industry naturally makes you think of the construction phase of a project. However, a major part in the overall project duration is the design phase, which tends to be around 40% of the overall project duration.

There are a lot of interesting and innovative approaches being taken in the construction phase of the project to cut time out of the program and to increase the quality of the installation. However, the design phase is lagging behind significantly on this front.

It is interesting and quite surprising to read that 32% of construction defects in buildings come from the design phase of a project. 3D drawing software programs indirectly have a major role to play in this.

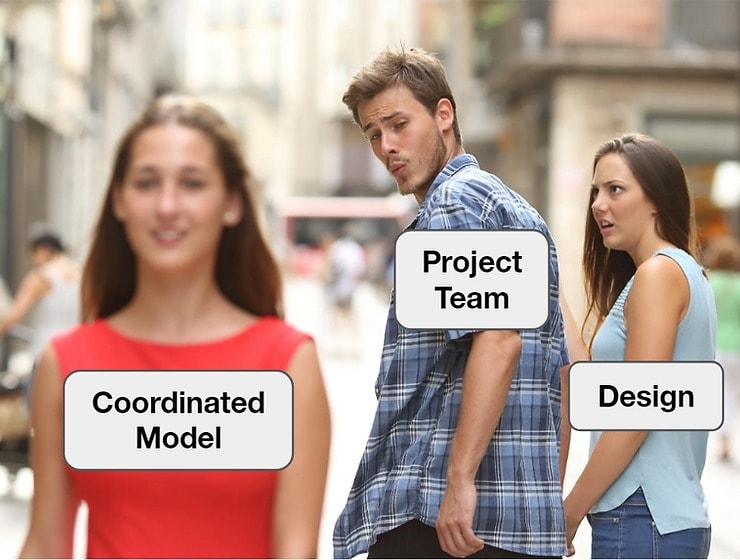

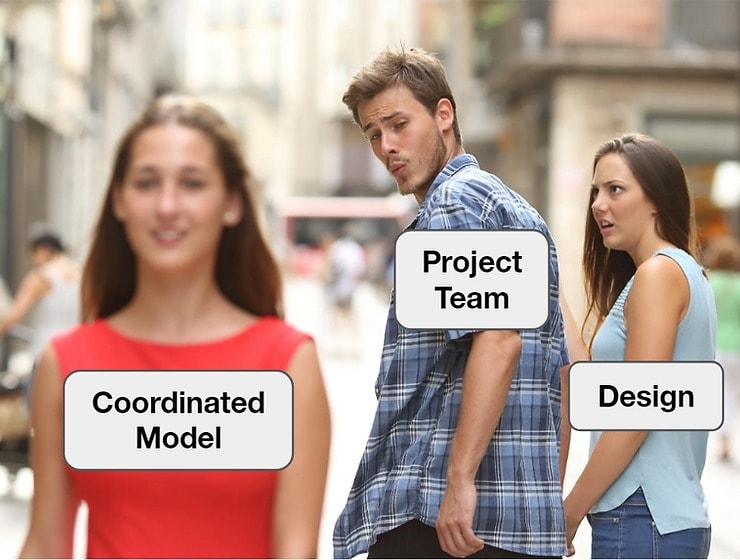

The reality is that 3D drawing and coordination software programs are detrimental to the design phase if started and prioritised too soon. Unfortunately, this is often the case.

There is too much emphasis placed on minor components of each discipline looking pretty and coordinated in a 3D model long before it should be a priority. Focus is taken away from the system design and ensuring that the design is compliant, fit for purpose, and most importantly provides the best value to the client.

Providing a well thought through design takes the back seat; riding in shotgun is the pretty looking coordinated model.

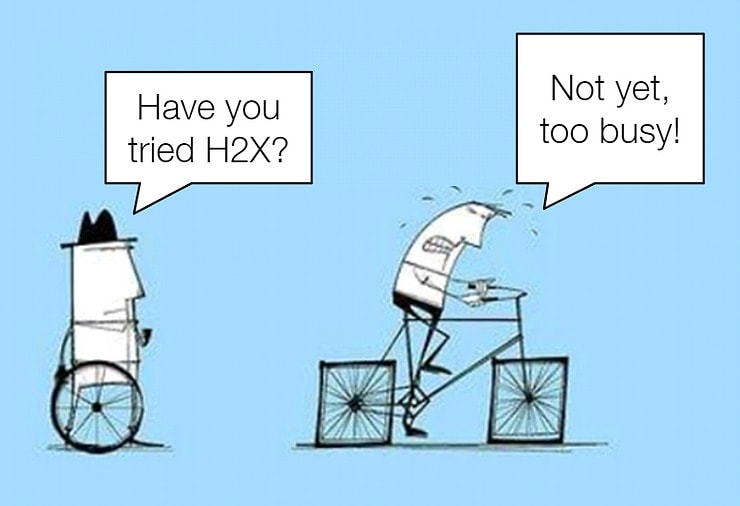

Processes need to be incorporated into the design phase that tick the same boxes as ‘prefabrication’ – organised, quality, efficient, and innovative. The traditional process of drawing and measuring, inputting into various spreadsheets, looking up tables, and searching for manufacturer’s data online has become outdated.

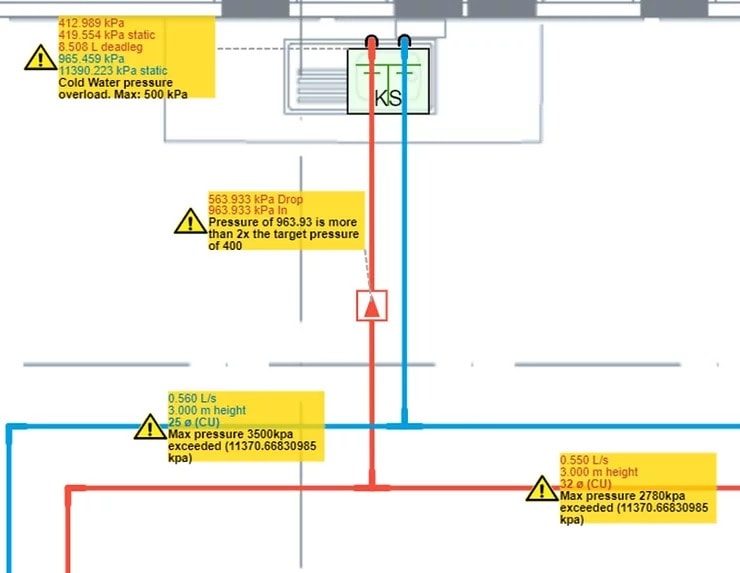

At H2X, some of our core features, like pipe volume calculator, pressure drop calculator and Pipe Velocity calculator helps automate the tedious calculations that take up a significant amount of the engineer’s time and are susceptible to human error. By automating calculations, we are freeing the engineer’s time to focus on assessing and solving the fundamental design options that provide the best value to that project.

In addition to that, we offer a platform that creates standardisation across the office and is very easy to audit internally or externally. This is an incredibly important part of the design phase that can often be overlooked or even rushed due to time constraints.

Having time to focus on the design rather than coordinating too early in the project will go a long way to decrease the 32% of defects that are attributed to the design stage.

Start your free trial of H2X’s plumbing design and calculation software today – https://app.h2xengineering.com/signup

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP