How To Calculate Air Velocity In A Duct

Learn how to accurately calculate air velocity in ducts for HVAC systems. Get essential tips and techniques in our comprehensive guide below!

Introduction

Mastering the calculation of air velocity in duct systems is an essential skill for efficient HVAC design and maintenance.

This article aims to provide a clear, concise, and technical walkthrough of air velocity calculations, ensuring you have the knowledge needed for optimal ductwork design.

Why It Is Important To Calculate Air Velocity In A Duct

Accurate air velocity calculation in ducts is crucial for appropriate duct sizing.

Additionally, a solid grasp of airflow dynamics aids in troubleshooting and maintaining HVAC systems, ensuring they operate effectively for longer.

What Could Go Wrong If Done Incorrectly

Incorrect calculations can lead to a myriad of issues, such as:

- Excessive noise

- Increased stress on the system

- Discomfort due to drafts

- Insufficient ventilation

- Poor air quality

- Temperature inconsistencies

Both extremes, high to low velocities, often lead to higher operational costs and reduced system lifespan.

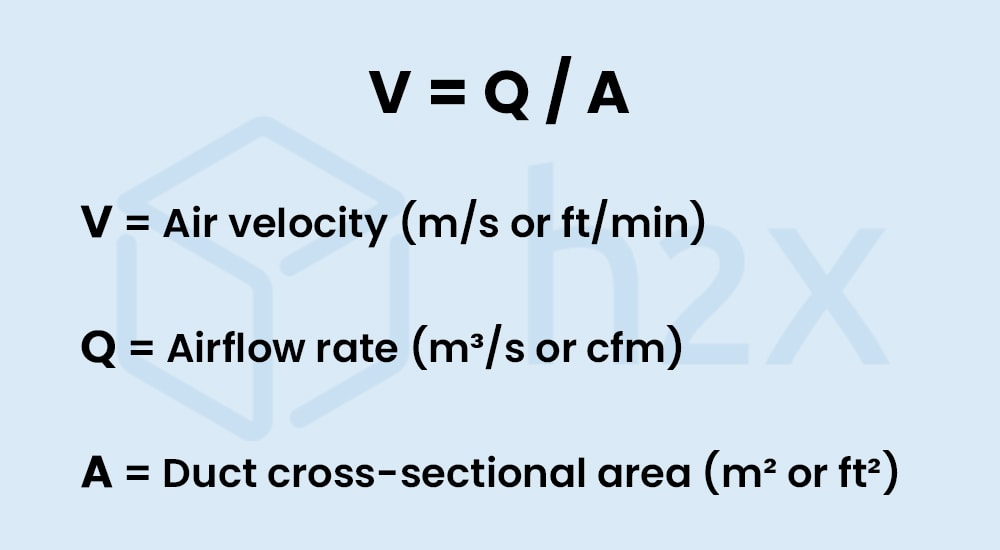

Formula To Calculate Air Velocity In A Duct

To calculate air velocity in ducts, the following formula is used:

V = Q / A

Where:

– V = Air velocity (m/s or ft/min)

– Q = Airflow rate (m3/s or cfm)

– A = Duct cross-sectional area (m2 or ft2)

For circular ducts, the area is calculated as A = π × r2, where r is the radius of the duct.

For rectangular ducts, the area is calculated as A = l × w, where l is the length and w is the width of the duct.

Hypothetical Calculation Example

Metric Example (Circular Duct):

• Diameter of duct: 0.5 meters

• Radius of duct: 0.25 meters

• Airflow rate (Q): 0.3 m3/s

• Area (A) = π×(0.25)2 = 0.196 m2

• Air velocity (V) = 0.3/0.196 = 1.53 m/s

Imperial Example (Circular Duct):

• Diameter of duct: 20 inches

• Radius of duct: 10 inches (converted to feet: 0.833 ft)

• Airflow rate (Q): 500 cfm

• Area (A) = π×(0.833)2 = 2.18 ft2

• Air velocity (V) = 500/2.18 = 229 ft/min

Metric Example (Rectangular Duct):

• Length of duct: 0.6 meters

• Width of duct: 0.4 meters

• Airflow rate (Q): 0.3 m3/s

• Area (A) = 0.6×0.4 = 0.24 m2

• Air velocity (V) = 0.3/0.24 = 1.25 m/s

Imperial Example (Rectangular Duct):

• Length of duct: 24 inches (converted to feet: 2 ft)

• Width of duct: 16 inches (converted to feet: 1.33 ft)

• Airflow rate (Q): 500 cfm

• Area (A) = 2×1.33 = 2.66 ft2

• Air velocity (V) = 500/2.66 = 188 ft/min

Conclusion

Accurate calculation of air velocity in ducts is a cornerstone of effective HVAC design and maintenance.

By understanding and applying the principles outlined in this guide, mechanical engineers can ensure their systems deliver optimal performance, comfort, and longevity.

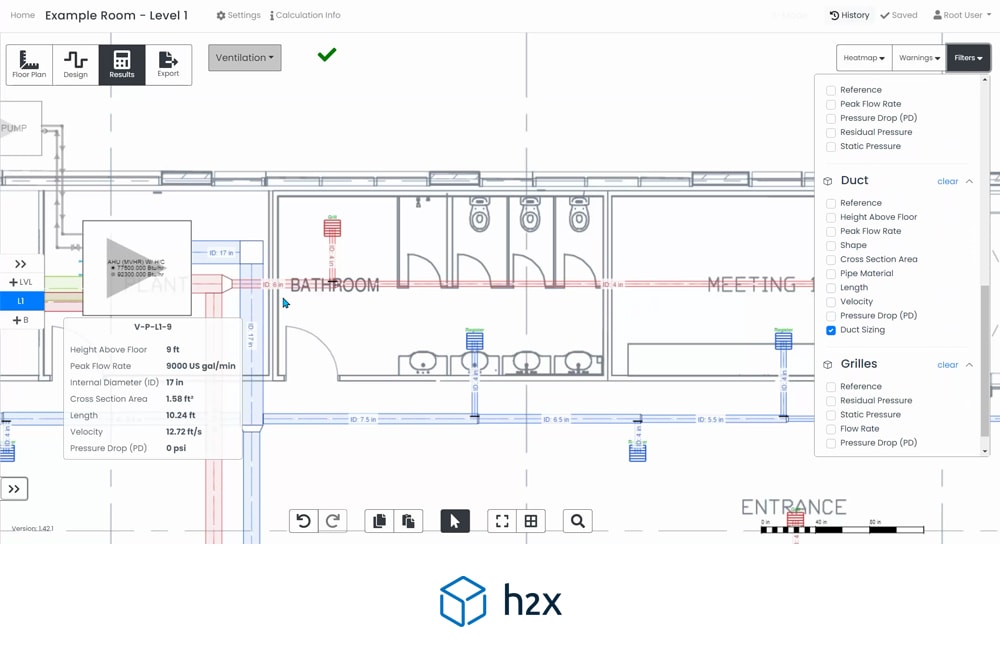

h2x is a design tool built to ensure compliance, efficiency, accuracy and collaboration.

The software simplifies calculations for flow rate, velocity, pressure, pump duty, plant size, and recirculation systems, freeing you from tedious math and enabling you to concentrate on project design.

h2x simplifies the design process for engineers, enabling them to create top-notch designs efficiently while ensuring compliance with industry standards.

The tool has sized millions of kilometres of pipes in projects across the world.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

FAQs

Why is air velocity crucial in duct design?

It determines duct sizing, influences noise levels, and ensures efficient air distribution.

What is the maximum recommended velocity?

For residential systems, maintaining supply duct velocities below 800 ft/min (4 m/s) minimises noise and enhances comfort.

In commercial settings, slightly higher velocities are generally acceptable.

Does duct shape affect air velocity calculations?

Yes, different shapes have varying cross-sectional areas, which affects the velocity for a given air flow rate.

The calculation principle remains the same, but the duct area formula differs.

Is this calculation method applicable regardless of duct material?

Absolutely.

While the duct material doesn’t affect the air velocity calculation, it may influence other factors like noise and system durability.

How can I determine the appropriate air velocity for different types of HVAC systems?

Determining the appropriate air velocity for HVAC systems involves considering factors such as the size of the space being conditioned, the type of equipment used, and the desired level of comfort.

Different systems may have different velocity requirements based on their specific design and intended use.

What are some common challenges or pitfalls to avoid when performing air velocity calculations for ductwork design and maintenance?

Common challenges when performing air velocity calculations include accurately measuring air flow rates, accounting for variations in duct shape and size, and accounting for factors like turbulence or obstructions in the ductwork.

It’s important to use accurate measurements and reliable calculation methods to avoid errors that could lead to inefficient system performance or discomfort for building occupants.

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!

h2x: All-In-One Tool for Calculating, Designing, Estimating, and Paperwork

Testimonials

What Installers Say

What Consultants Say

A game changer for the humble plumber. Incredible.

Brad Winkel

Director at Queenstown Plumbing

Brilliant, simple and easy to use. Game changer.

James Major

Director at Hubb

Big time game changer to the industry!

Viv Jude

Director at UHC

Incredible software! Super user-friendly and allows you to save so much time.

Devni Gamage

Engineer at DMA

h2x is great software, our company use it nearly every day. It is easy to use with direct conversion from h2x to Revit.

Callum Craig

Engineer at WDE

h2x is fantastic software. It is very easy to use and the ability to output to Revit is a fantastic time saver.

Joe Kirrane

Engineer at MEP