We Need to Stop Using ‘Length’ as a Dead Leg Design Parameter

No matter what type of building you are designing, you will likely have a design parameter relating to dead legs. The reason for the design parameter is usually to align with one of the following client requests...

No matter what type of building you are designing, you will likely have a design parameter relating to dead legs.

The reason for the design parameter is usually to align with one of the following client requests:

User Comfort

To limit the wait time for heated water at the outlet e.g. in an apartment or hotel building

Public Health

To limit the amount of microbial growth in stagnant water e.g. in a healthcare building

Sustainability

To reduce the amount of wasted ‘dead’ water at the outlet

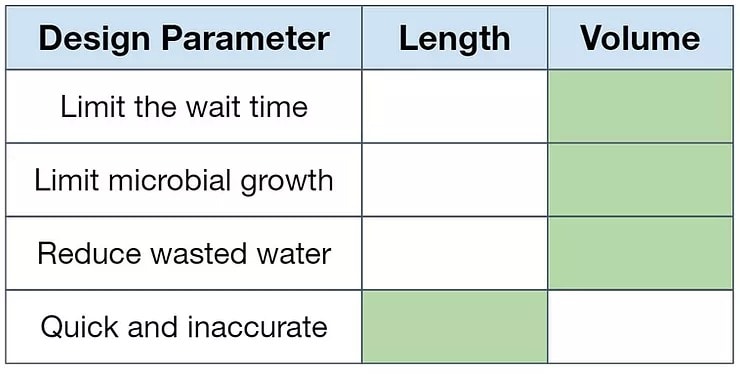

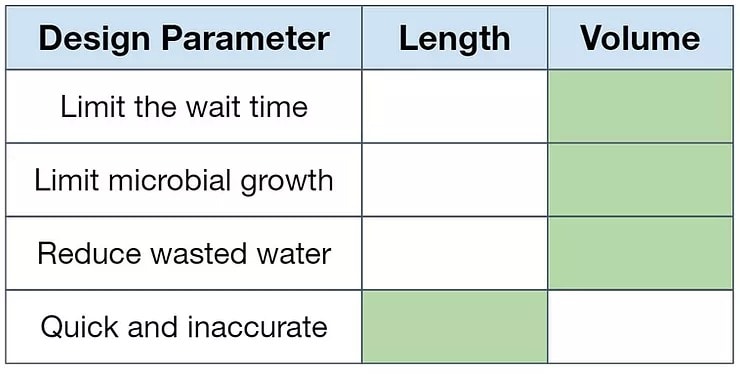

There are two common methods used to measure dead legs – the length of the pipe or the volume of water within the pipe.

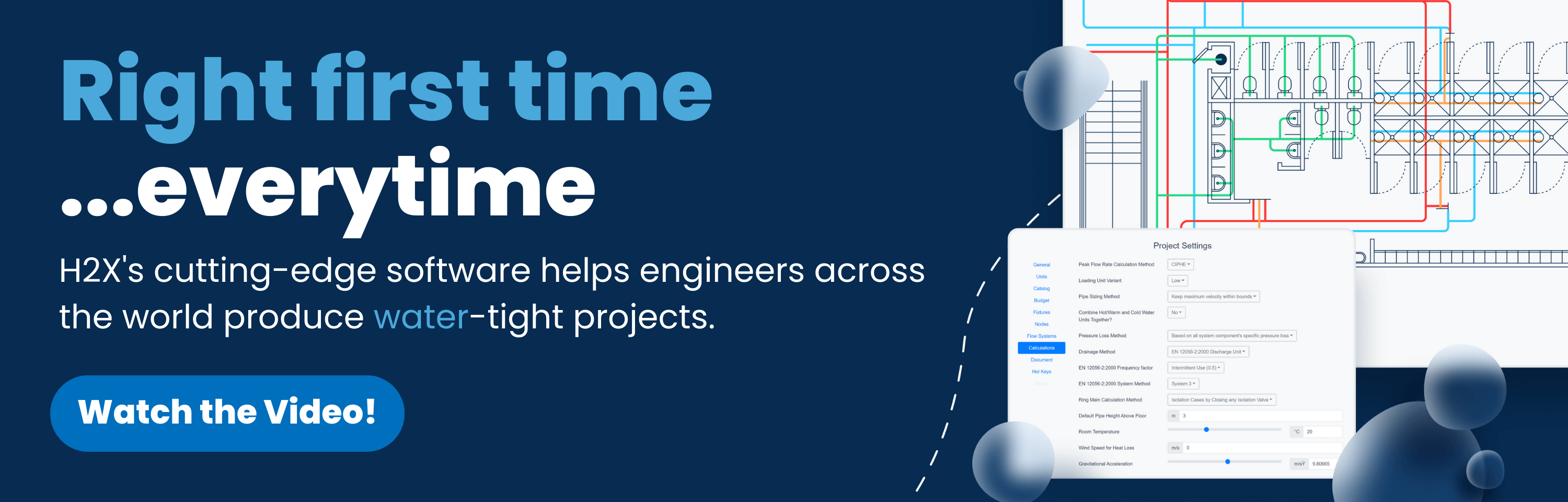

Each method has their pros and cons but effectively, as illustrated in the table below, if you are looking for an outcome that is anything but ‘quick and inaccurate’, you need to calculate based on the volume of water within the dead leg pipe.

Example #1

Your client has asked you to ensure that there is a maximum wait time of 30 seconds for heated water at any outlet.

How do you comply with this by using length? It is not possible.

How do you comply with this by using volume? Internal diameter of the pipe, multiplied by the length, divided by the flow rate of the outlet.

Example #2

Your client has asked you to ensure that there is a maximum dead leg of 2L dead leg to limit microbial growth.

How do you comply with this by using length? It is not possible.

How do you comply with this by using volume? Internal diameter of the pipe, multiplied by the length.

Example #3

Your client has asked you to ensure that there is a maximum dead leg of 3L dead leg to ensure you comply with sustainability guidelines.

How do you comply with this by using length? It is not possible.

How do you comply with this by using volume? Internal diameter of the pipe, multiplied by the length.

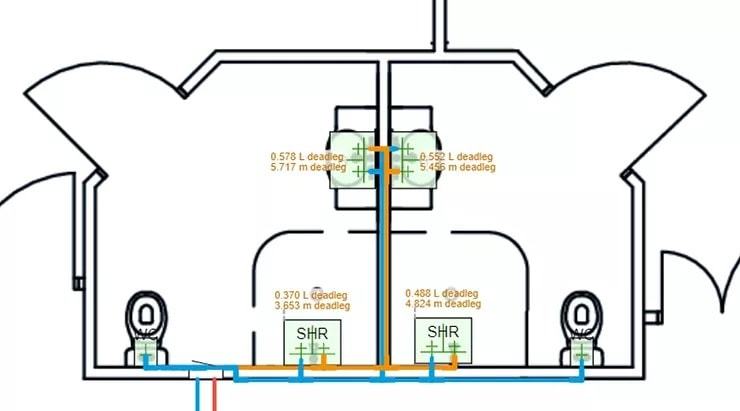

When using H2X, both the length and volume of a dead leg are automatically calculated for you at each individual outlet.

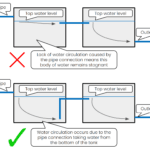

There is a difference in opinion in the industry on whether the pipework from the circulating system to the mixing valve should be included in the dead leg calculation. If your design parameter is in relation to wait time or increasing sustainability, it must be included. If your design parameter is to minimise microbial growth, there is an argument that it does not need to be included. Legionella should have been removed from the water as it has been heated, and it is not reintroduced until it encounters cold water at the mixing valve.

The below is an example of the results that you can export from H2X and append to your design report or maintenance manual.

Start your free trial with H2X and gain confidence that your dead legs are compliant. Also, make sure to download our free Dead Leg App, which will assist in ensuring dead legs are compliant whether you are in the office or out on site.

5 Reasons Industry Experts Design with H2X

- Exceptional Support

- Proven & Reliable

- Ease Of Use

- Built By The Industry

- Worldwide User Base

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!