h2x Tools

Heat Loss Calculator

Using the Heat Loss Calculator, calculate the loss of heat of a building, room by room.

Get accurate results with this simple, yet powerful tool.

Other Users Found These Calculators Useful

Calculate friction losses through a pipe quickly and easily, eliminating the need to perform complex mathematical calculations manually.

Calculate velocity through a pipe quickly and easily, eliminating the need to perform complex mathematical calculations manually.

Find out how much water volume is in your pipe by simply inputting the pipe's diameter and length.

Variables:

Materials, Air Changes, Area, and Temperature

Materials

Building materials directly impact heat loss. Materials with good insulation properties like fiberglass or mineral wool help maintain indoor temperature, whereas conductive materials such as metal and glass facilitate heat escape.

Air Changes

Air changes, through ventilation or leakage, can cause significant loss of heat. For example, buildings that are well-sealed and have controlled ventilation systems tend to lose less heat compared to those with air leakages.

Area

The building's surface area exposed to the outside environment correlates with heat loss. Buildings with a larger external surface area tend to lose heat more rapidly due to increased opportunities for heat transfer.

Temperature

The difference between the indoor and outdoor temperature plays a significant role in heat loss. Higher temperature differentials cause heat to flow more quickly from inside to outside, increasing loss of heat.

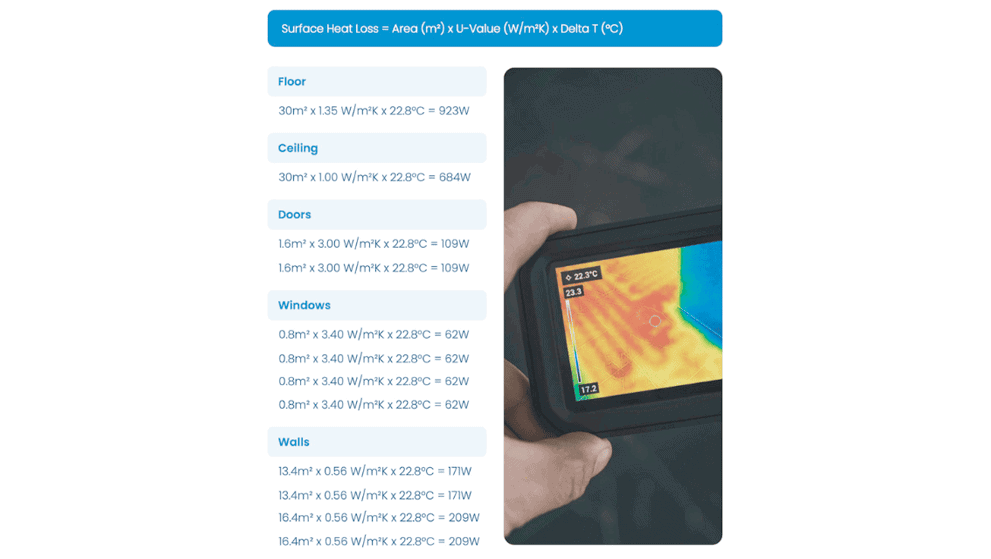

Heat Loss Formula

There are two calculations for heat loss, they should be calculated separately and combined together:

Transmission Losses

Each component of the building (walls, roof, windows, etc.) has its own U-value, measuring heat passage and must be calculated separately.

They are calculated using the formula:

Components

- Area = m²

- U-Value = W/m²K

- Temperature = °C

Ventilation Losses

They occur when warm air inside the building is replaced by colder outside air through ventilation or infiltration.

They can be calculated using the formula:

Components

- Volume = m³

- Temperature = °C

- Specific Heat Capacity = ~0.33

What is the Heat Loss Calculation Used For?

Heat loss refers to the amount of energy that escapes from a building or a home, usually through doors, windows, floors, walls, and the roof.

The lower the heat loss, the less energy you need to keep your home warm, making your house more energy-efficient and reducing your heating bills.

There are several reasons why using our Heat Loss Calculator is vital to calculating loss of heat:

- Helps design and size heating systems accurately.

- Enables greater efficiency in resource utilisation, lowering expenses and environmental impact.

- Can help you identify problem areas in your home where you could improve the loss of heat.

To learn more, check out our blog article Calculating Heat Loss.

Why Use a Heat Loss Calculator?

There are several benefits of using a Heat Loss Calculator, including:

Increased Accuracy:

Determine accurate values by eliminating the possibility of human error when calculating fluid pressure drop by hand.

Time-Saving:

Saves time by providing quick and easy calculations, eliminating the case to perform complex mathematical calcs manually.

Easy to Use:

User-friendly and requires no special training or technical knowledge. Just provide the input and read the detailed results.

Cost-Effective:

Can save money by reducing the number of time spent on manual and long calculations for a project, and avoiding costly mistakes.

FAQs

Resources

Want to Learn More About This Topic?

Heat Pump eBook

This free eBook breaks down everything engineers need to know about heat pump design.

Calculating Heat Loss

Explore everything about calculating heat loss - what it is, why it's important, how you can calculate it, etc.

Boiler Systems vs. Heat Pumps

Making an informed choice about boiler systems vs. heat pumps involves understanding many things...

See what h2x can do

There's a reason we are rated 4.9/5 for customer support on Capterra. Our integrated help button

means that a real engineer will assist with any design query, no matter how big or small.