Why Accurate Calculations Are Crucial in Heat Pump Designs

For decades now, engineers have been relying on rule of thumb and their own prior experience when producing calculations for typical gas boiler heating systems. Despite this approach having been effective in the past, change is critical for successful heat pump installations.

For decades now, engineers have been relying on rule of thumb and their own prior experience when producing calculations for typical gas boiler heating systems. Despite this approach having been effective in the past, change is critical for successful heat pump installations.

Whilst utilising the rule of thumb and oversizing has no significant implications when it comes to traditional systems, for heat pumps it’s a different story entirely.

As heat pump installations become more widespread, the consequences of not undertaking accurate calculations in the design phase will cause serious issues. Long-term, it will dramatically slow down the adoption of heat pumps.

That’s why in this article, we’re going to be delving into heat pump calculations. This will involve outlining errors that need to be avoided and examining how software is optimising processes and outcomes.

Let’s start by looking at why heat pumps have become such a critical area of focus for engineers.

Why are heat pumps important for engineers?

Globally, heat accounts for nearly half of all energy consumption and 40% of energy-related carbon dioxide emissions.¹ In the UK, homes are responsible for 25% of the country’s carbon emissions, making them one of the biggest contributors to the country’s greenhouse gas emissions. ²

As a result, last year the government announced a scheme designed to encourage UK property owners to install low carbon heating systems like heat pumps.³ Following the unveiling of these plans, heat pumps have become a hot topic of discussion. Consumers have also become more interested in heat pumps due to installation benefits, including:

- Efficient energy use: With heat pumps, far less energy is used to produce heating and hot water, thereby helping to reduce energy bills.

- Decreased carbon footprint: Unlike traditional gas boilers, heat pumps produce significantly fewer carbon emissions.

However, accessing these and other heat pump-associated benefits requires successful installation, and this, in turn, relies on efficient design and calculation processes.

The vast majority of problems associated with a heat pump system can be traced back to errors and inefficiencies in the design processes. Unfortunately, this isn’t helped by the fact that estimates suggest that there are only 3,000 trained heat pump engineers in the UK.⁴

Given plans to expand the installation of heat pumps and the vital importance of correct design calculations, engineers need to be armed with the tools and knowledge to ensure efficient and successful heat pump systems are produced on a consistent basis.

Heat pump systems

Before the design and calculations of a heat pump can begin the most appropriate system needs to be identified. That means choosing between the two most commonly used types of heat pump, which are:

- Air-source heat pumps: These heat pumps extract energy contained within ambient air and upgrade the temperature. As the external temperature varies throughout the heating system, the performance of an air-source heat pump will vary over the annual cycle, so ‘seasonal’ efficiencies should be considered.

- Ground-source heat pumps: Heat is transferred from the ground outside to heat radiators or underfloor heating. Whilst they are typically more efficient than air-source heat pumps, they are expensive and time-consuming to install, requiring significant excavation work in order to lay the necessary piping.

Choosing which heat pump is suitable depends on a variety of factors specific to the project. This means that, when embarking upon their designs, engineers need to consider:

- How much space is there for the heat pump?

- Are there any noise restrictions that need to be considered?

- Does the heat pump need to double up as a cooling unit in the summer?

Answering these questions makes it much easier to correctly identify the most appropriate heat pump system and thereby avoid potential issues that could otherwise arise during the building process.

Typical heat pump design errors

As we’ve already outlined, design and calculation are both vital to successful heat pump installation. That’s because getting designs and calculations right the first time not only helps to avoid errors and reduce project costs, but also ensures an effective system that produces the desired results for end users.

Let’s take a look at some of the most common errors that engineers need to avoid in order to ensure their design produces the desired outcomes.

Oversizing heat pumps

Ensuring that designs include the correct size of heat pump is critical to the overall success of a project. Surprisingly, it is actually better to undersize a heat pump during the design than to oversize it.

This is true for a variety of reasons, namely because oversizing a heat pump:

- Will cause the heat pump to cycle on/off frequently, which will damage the motor

- Makes the building cycle between being too hot and then too cold rather than maintaining a comfortable temperature

- Results in inefficiency by using more electricity, making the heat pump less sustainable and defeating the purpose of the installation

- Makes the heat pump more expensive to purchase

- Means the system will be much noisier than it needs to be

Undersizing heat pumps

While undersizing a heat pump is more desirable than oversizing, it will still result in a number of undesirable outcomes that engineers want to avoid. This includes:

- The heat pump may not be capable of heating the space up to the desired temperature

- If the heat pump is capable of heating the space, it will take a long time to do so

- Making the heat pump work harder than it wants to will create mechanical problems in the future

- Increased use of electricity which makes the heat pump less sustainable, once again defeating the purpose of installation

Undersizing pipes

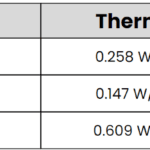

Pipes generally need to be larger for heat pumps than for a traditional gas boiler system. This is due to the fact that a heat pump system needs to run with higher flow rates due to their smaller Delta T.

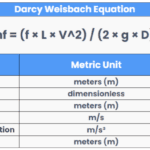

If you design and install pipework that is too small, the velocity will be higher than 1m/sec — the maximum velocity recommended by MCS and CIBSE. This will damage the pipes due to erosion corrosion. Additionally, this can result in a void warranty from the manufacturer of the pipe.

High velocity causes more noise in the system, which is obviously undesirable. It will also create high amounts of pressure loss, which means the recirculation pump may not work effectively.

“Heat pumps require 28mm pipework”

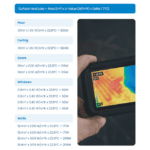

It is commonly stated throughout the industry that heat pumps require 28mm pipes. However, this is a myth, is misleading, and should be avoided. The reality is that rule of thumb, such as this, needs to be avoided throughout the heat pump design process.

The “28mm pipe” emerges from the understanding that heat pumps require larger flow rates than gas boilers. So where a gas boiler system would generally need a 15mm or 22mm pipe, people are using rule of thumb to ‘guesstimate’ that 28mm should be appropriate for heat pumps.

Whilst it is correct in some instances, for example when the pipe is between 6.6kW and 11kW, it isn’t always correct.

Every pipe needs to be accurately sized based on the flow rate/kW rating. The below chart outlines the correct pipe size for a Delta T of 5 degrees and a maximum velocity of 1m/sec:

| 15mm | 3kW |

| 22mm | 6.5kW |

| 28mm | 11kW |

| 35mm | 17kW |

| 42mm | 25kW |

| 54mm | 42kW |

How software can help engineers

As described above, using rule of thumb based on previous experience will not work for heat pump designs.

In fact, relying on rule of thumb can result in a number of issues, including:

- A poorly performing heat pump system

- Unhappy customers

- Investing time and resources going back to fix systems

Given the complex nature of the calculations that need to be undertaken, and the need for efficient solutions to make up for the skill shortage amongst engineers, heating design software is starting to play an increasingly important role.

Innovative software solutions that improve upon traditional design and calculation methods are now available. These tools allow engineers to undertake automatic calculations, most notably the pipe sizes and heat load on the heat pump.

With the help of these solutions, engineers can:

- Automate the complex calculations

- Export detailed drawings with an accurate bill of materials

- Be confident in a high-quality heat pump installation

Remember, there are a range of solutions available, but identifying one that brings together design and calculations can streamline processes, increase productivity and facilitate consistently outstanding designs.

Create efficient and flawless systems with H2X

At H2X, we understand efficient heat pump designs require processes that go beyond rule of thumb. That’s why we designed our software with a simple user interface that allows engineers to easily create accurate designs with levels of detail previously unattainable.

Using H2X, engineers can:

- Automate heating system calculations by:

- Sketching the pipe layout

- Adding the heat emitters

- Setting the properties such as the Delta T

- Export an automated Bill of Materials and a professional PDF to give to their client

Whether you are rushing to complete a tender or creating drawings for installations, H2X is a solution that will help you.

You can check out this case study to learn more about how H2X is helping engineers to create successful heat pump designs. If you’re ready to transform your heat pump calculation process and produce better, more efficient designs, book a demo with us today.

² Over a third of British households miss out on bill savings by not changing home energy use

⁴ Shortage of trained heat pump installers could set back net zero

5 Reasons Industry Experts Design with H2X

- Exceptional Support

- Proven & Reliable

- Ease Of Use

- Built By The Industry

- Worldwide User Base

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!