Viking Plastics

What is a Grease Trap?

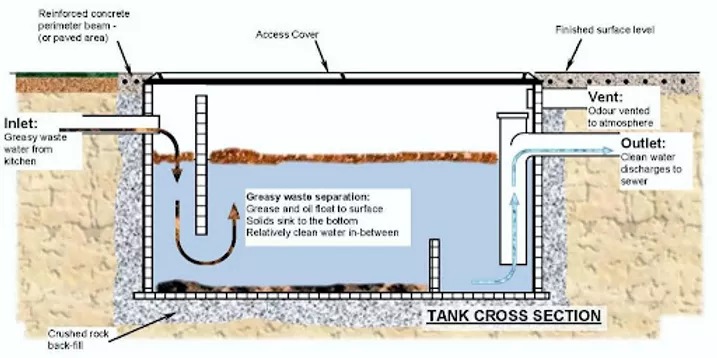

A grease trap (also known as a grease interceptor, grease arrestor or food and oil interceptor) is a holding tank with a number of baffles. It is specifically designed to slow the flow of warm/hot greasy wastewater from commercial kitchens and food preparation areas allowing the wastewater to cool. As the water cools, suspended fats, oil and grease from day to day cooking separate and float to the top, solids settle on the bottom and the cleaner and cooler water is discharged to the sewer.

The floating fats, oil and grease and the settled food solid will accumulate over time. This means the trap will need to be pumped out at regular intervals by a licensed trade waste collection contractor. The frequency may range from several weeks to several months. The licensed contractor will use a suction pump to remove all of the contents and wash and scrape the walls and baffles of the grease trap. Installing a larger grease trap may reduce the frequency and ongoing cost of pump-outs.

Why does a business need a grease trap?

By law, local water authorities require that all fats, oils and grease from all commercial food preparation businesses must not be discharged to the sewer system. Grease traps are required to prevent most fats, oils and grease from entering the sewer system where they can solidify and build up to cause blockages, overflows or overload wastewater treatment plants.

It is also important to prevent hot liquids from entering a plastic (PVC) sewer system. The pipes can melt and buckle if the wastewater discharged to the sewer is too hot.

Why Plastic Grease Traps?

Plastic grease traps are commonly made from polyethylene and other poly materials for increased efficiency and durability when placed in heavy use. These grease traps are made from a strong chemical compound increasing the longevity of the equipment as it cannot rust like metal grease traps. A plastic grease trap is also easier to repair than other inceptor models made from concrete that are located below the ground. When a concrete interceptor becomes cracked or the walls are fractured, the old equipment will often be replaced by lowering a plastic grease trap into the eroded concrete unit.

Do grease traps need to be an approved design?

Water authorities throughout Australia set the design specifications for grease traps. Viking Plastics’ grease traps are approved for use in virtually all regions of Australia. We will supply the correctly designed grease trap for your client’s particular locality.

In some large metropolitan cities, it is the water supply company that set the design specifications. In other areas, especially rural areas, it is usually the local council. In Melbourne, trade waste is governed by City West Water, South East Water and Yarra Valley Water. In Sydney, it is Sydney Water. In Brisbane, it is the Brisbane City Council. On the Gold Coast, it is the Gold Coast council. Likewise, on the Sunshine Coast, the city council is responsible. In Adelaide, trade waste is governed by SA Water which covers the whole state. Water Corporation governs Western Australia.

Your client will need a trade waste agreement with their local authority and formal approval from that authority before being allowed to discharge trade waste to the sewer.

To find a list of water authorities, click here.

How often will the grease trap need to be cleaned out?

The floating fats, oil and grease and the settled food solid will accumulate over time. This means your client’s grease trap will need to be pumped out at regular intervals by a licensed trade waste collection contractor. The licensed contractor will use a suction pump to remove all of the contents and wash and scrape the walls and baffles of the grease trap.

The frequency of cleaning will be set in your client’s trade waste agreement and will depend upon the capacity of the grease trap and the type of business. The frequency may range from several weeks to several months. Installing a larger grease trap will reduce the frequency and ongoing cost of pump-outs.

Typical maintenance would include removing all the contents, including the wastewater and grease from the unit. Once empty, run the sinks to fill the unit with cold water while inspecting for any issues such as leaks caused by wear-and-tear. Any issues can be fixed and the grease trap placed back into operation.

What tank options are available?

Viking Plastics offers above ground and below ground Paneltim® tanks. Paneltim® is an innovative 50mm thick, dual skin sandwich panel with an internal cross-rib-cell structure that is lightweight yet offers superior strength and rigidity in both length and width.

● Larger above-ground tanks (1100 litres and above) are typically more economical when constructed from Paneltim®.

● Paneltim® below ground tanks are cost-competitive as they offer faster and lower cost below ground installation due to the superior strength and rigidity of Paneltim® that avoids the need for poured concrete reinforcement. Paneltim® grease traps can be backfilled with crushed rock or stabilised sand.

Above Ground Grease Traps

Features

● Suitable for above-ground installation

● Designed to comply with local water authority specifications

● Pipe fittings are fully welded for superior seals

● Fitted with 100mm inlet, outlet and vent plain pipe nozzles

● Circular, quick release, air-tight, access covers prevent the emission of foul odours and provide quick and easy access for tank pump-outs and cleaning

● Optional hinged lids can be supplied

Below Ground Grease Traps

Features

● Suitable for below ground installation

● Designed to comply with local water authority specifications

● Pipe fittings are fully welded for superior seals

● Fitted with 100mm inlet and outlet and a 50mm vent plain pipe nozzles

● Access covers (sold separately) capable of being removed by one man should be fitted on top for easy access and tank cleaning

● Access covers are available in various types (concrete in-fill, solid top or tiling edge), numerous sizes and several weight loadings (pedestrian, car or truck)

For further information, contact Viking Plastics T: 03 9587 2297 W: www.vikingplastics.com.au E: info@vikingplastics.com.au

Did you know?

You can design Vikings Paneltim® Grease Traps in H2X.

Test it out for yourself by starting a free trial here.

5 Reasons Industry Experts Design with H2X

- Exceptional Support

- Proven & Reliable

- Ease Of Use

- Built By The Industry

- Worldwide User Base

What's in the Pipeline?

Get access to our monthly roundup of news and insights

You may unsubscribe from these communications at any time. For more information, please review our Privacy Policy.