How to Improve the Efficiency of Your Design Process

Efficient design in engineering is crucial. For any given engineering project, there are myriad different decisions and calculations. Each one might not seem important on its own, but together they have a huge impact on the end result.

Efficient design in engineering is crucial. For any given engineering project, there are myriad different decisions and calculations. Each one might not seem important on its own, but together they have a huge impact on the end result. Every aspect of the system must be carefully designed to ensure that it’s safe, efficient, and fit for purpose.

The design is a blueprint of what will be constructed, and if there are errors in the design process, it can be difficult to correct them later on in the project. This is especially true if you’re still using legacy processes.

Research shows that errors in engineering and design cause almost 70% of all rework in construction.¹ Another study found that almost 80% of cost deviations on engineering projects are design-related.²

That’s why in this article, we will look at how engineers can improve the efficiency of the design process and produce better, high-quality outcomes with the help of innovative tools and solutions.

Suggested reading: Read more about how new solutions are improving legacy design processes in our recent blog post — H2X vs Spreadsheets

The importance of design efficiency

All engineering projects are born from a problem and the need to find a solution — engineers follow a design process to make sure that the solution is efficient and effective. Design, and by implication, design efficiency, is amongst the most important aspects of any project — and it’s the very first step any engineer should take.

As simplistic as it may sound, design defects are likely to cause problems later on in the project. Even the slightest design error can cause significant delays and cost overruns — both of which can make it difficult to win future business once the project is complete.

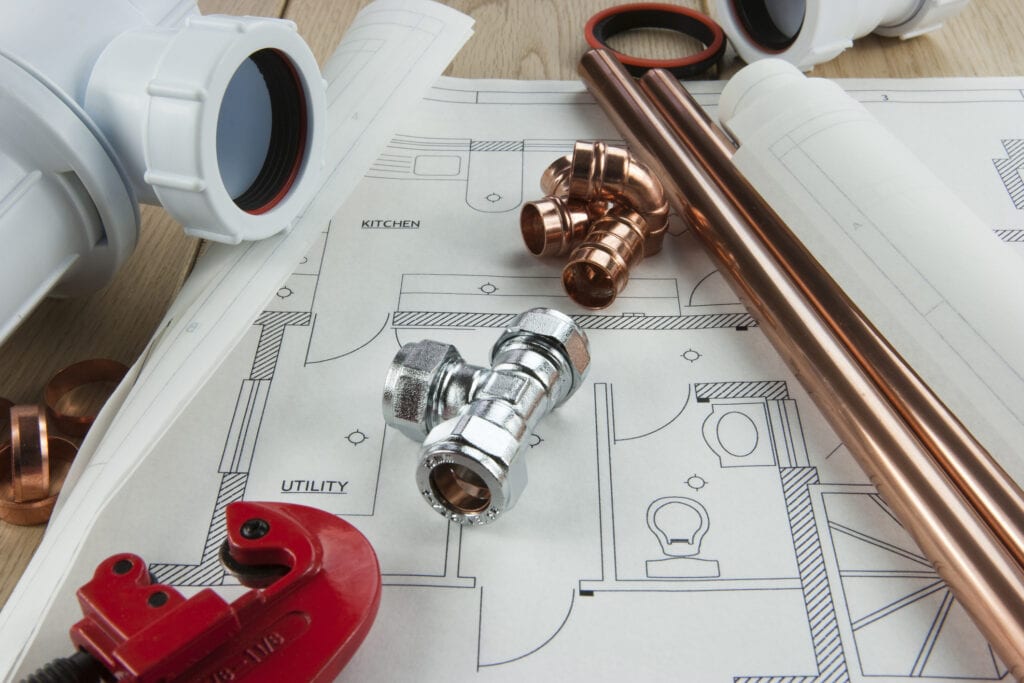

Legacy design processes

Legacy design processes have been passed down through generations, tweaked and adapted over time. As technologies and design needs change, legacy processes have trouble keeping up and adapting.

Unfortunately, legacy design processes are often time-consuming, repetitive, and tedious — all of which have the potential to limit business growth and negatively impact the final outcome of a project.

The current process still utilised by many engineers involves:

- Drawing the layout: The layout of a design must be created and refined. This often happens through several iterations to create a product that’s both effective and appealing to customers.

- Calculating the peak flow rate: The maximum amount of water that can flow past a given point must be calculated by manually counting what is connected downstream of each individual pipe.

- Sizing the pipework, valves and fittings: Each pipe and valve size is selected by determining what the velocity is at the calculated peak flow rate.

- Calculating the residual pressure: The residual pressure calculations are undertaken manually by measuring and counting the pressure loss through each pipe, valve, fitting and change in height.

- Calculating the static pressure: Another pressure calculation needs to be undertaken based on the ‘static’ flow rate to determine if pressure reduction valves are required in the system.

- Calculating the heat loss: In conjunction with parameters like room temperature, water flow and return temperature, insulation material and thickness, you need to calculate the heat loss of every pipe by measuring the length and undertaking a complex calculation.

- Checking the results: A manager will undertake a review of the design and calculations by manually reviewing the inputs in the spreadsheet and spot-checking some of the results against the design layout.

- Revit modeling: Once you’ve completed all the calculations, you have to build a 3D Revit model of the design layout and associated sizes.

- Design Iteration: As the architectural design layout changes the calculation process should start again to ensure your calculations are up to date.

As engineering projects become more complex, the legacy approach of relying on spreadsheets for calculations has become outdated. Not only is this method prone to errors, but it can also make it difficult to track progress, identify potential issues, and keep up with design iterations.

The bottom line is a new approach is required to ensure efficiency throughout the design process. Fortunately, the software can now provide that solution.

Introducing H2X

H2X is a cutting-edge software tool designed by engineers worldwide to automatically size water, heating, wastewater and gas systems. It’s already been used to design over 3,500 projects across a wide range of building types and use cases. Users consistently report that it increases quality and reduces design time by up to 72%.

‘User-friendly software that allows different design options to be quickly and accurately sized’ — Matthew Yanez, Director of Plumbing Design Solutions.

H2X offers a wide range of benefits for engineers in the design and calculation process. These benefits include, but are not limited to:

- Increased productivity

- Standardised outcomes

- Improved quality assurance

How H2X enhances design processes

H2X improves the way you design, calculate and draft your projects. We go beyond the rule of thumb to improve the efficiency of the design process.

That’s why we designed our software with a simple user interface that allows engineers to easily create accurate designs with levels of detail that were previously unattainable. This includes:

- Setting the calculation parameters: Quality control in engineering within the parameters, which can be changed at any time, that allow H2X to complete all of the calculations

- Design layout: Add equipment, pipes, and fixtures to the layout. When the design layout changes, drag the components to their new location for the calculations to dynamically update.

- Reviewing and exporting the results: Once you’re happy with your results in H2X, export the design into AutoCAD or Revit.

That is why users of H2X can design four times faster than with traditional methods while simultaneously improving both accuracy and compliance.

Reduce human error

With the precise and accurate detail that H2X can provide, there’s no possibility of human error and no need to rely on rule of thumb. Instead, the software highlights where problems arise within a specific design, issuing design warnings so these can be rectified early in the design phase.

This functionality makes it easier to troubleshoot issues and provides engineers with confidence that the design is accurate. Automated calculations also prevent simple mistakes from occurring that can have a big impact later on in the project.

Simplified sharing

H2X utilities cloud-based software, which means that engineers’ designs can easily be shared with project teams — both internally and externally. This encourages collaboration and ensures that all the necessary input required for the design is received from all the relevant stakeholders.

In addition to this, it works to improve the review process — allowing internal and external team members to review results directly in H2X.

Easily redesign

Even once the initial design is complete, architects often make changes at a later stage in the project. Historically, this has been a cause of frustration for engineers, often meaning that the design process has to begin again from scratch.

However, with H2X, this is a thing of the past. Using our software, engineers can make changes to the design as the project stages evolve whilst calculations update automatically, saving valuable time and resources.

‘Simple and easy to use and saves hours on re-design/recalculating when the architect changes the floor plans!’ — Nick Soden, Director at NAS Hydraulics

Seamless 3D models

Another key feature of H2X is the ability to import design directly to Revit. This allows engineers to generate a 3D model of all pipes, fittings, and valves within minutes with no chance of errors occurring from miscommunication between the designer and drafter.

This is crucial in improving the efficiency of teams. 3D models take around hours to complete. As H2X allows this to be done much quicker, engineers can focus more time and effort on the actual design, providing value to their clients.

Software that increases productivity and improves quality assurance

If you’re looking for a software solution that can help improve the efficiency of your design process, look no further than H2X. Our software is easy to access and ideal for teams of engineers looking to produce better, more efficient designs.

H2X was founded by engineers frustrated by tedious processes looking to provide the industry with a better solution. That’s why the software is designed to:

- Reduces human error

- Increase productivity

- Improves quality assurance

- Make sharing and reviews seamless

Ready to do away with legacy processes and improve design efficiency? Book a demo of H2X today.

¹ The Cost of Rework: Finding the Key to Improving Productivity in Construction.

² Cost and Time Impacts of Reworks in Building a Reinforced Concrete Structure.

5 Reasons Industry Experts Design with H2X

- Exceptional Support

- Proven & Reliable

- Ease Of Use

- Built By The Industry

- Worldwide User Base

What's in the Pipeline?

Get technical resources delivered to your inbox weekly!